DOWEX Ion Exchange Resins WATER CONDITIONING MANUAL

DOWEX Ion Exchange Resins WATER CONDITIONING MANUAL

DOWEX Ion Exchange Resins WATER CONDITIONING MANUAL

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Demineralization (Deionization) Process<br />

H2SO4 or HCl is usually used for cation resin regeneration at a rate of 2 to 4 ppm for each ppm of cation<br />

removed. Caustic soda (NaOH) is used at a rate of 1 to 2 ppm for each ppm of acid (e.g., HCl and H2SO4)<br />

removed by a weak base anion resin, or 2 to 3 ppm for each ppm of either strong or weak acid anion<br />

removed by a strong base anion resin. Mixed beds normally require 15–20% higher regenerant dosages<br />

than individual beds.<br />

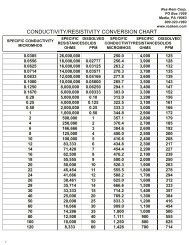

In Table 10, a typical water sample is analyzed before any treatment and after each of the three main<br />

steps in demineralization. The analyses indicate which constituents are removed from the water at each<br />

stage of the process.<br />

Constituent ppm as<br />

Table 10. Results of treatment by the demineralization process.<br />

Typical Raw<br />

Water<br />

Typical Strong<br />

Acid Cation<br />

Effluent after<br />

Degasification<br />

Typical Weak<br />

Base Anion<br />

Effluent after<br />

Degasification<br />

Typical Strong<br />

Base Anion<br />

Effluent<br />

Calcium CaCO3 150 Nil Nil Nil<br />

Magnesium CaCO3 50 Nil Nil Nil<br />

Sodium CaCO3 50 0–5 0–5 0–5<br />

Hydrogen CaCO3 0 100 0 0<br />

Total electrolyte CaCO3 250 100 0–5 0–5<br />

Bicarbonate CaCO3 150 0 0 0<br />

Carbonate CaCO3 0 0 0 0<br />

Hydroxide CaCO3 0 0 0 0–5<br />

Sulfate CaCO3 50 50 0 0<br />

Chloride CaCO3 50 50 0–5 0<br />

Nitrate CaCO3 0 0 0 0<br />

M Alk CaCO3 150 0 0–5 0–5<br />

P Alk CaCO3 0 0 0 0–5<br />

Carbon dioxide CO2 10 5 5 0<br />

pH — 7.5 2.0 7.0 7–9<br />

Silica SiO2 10 10 10 0–0.1<br />

7.3 Equipment Required<br />

A demineralization system may consist of a number of individual ion exchange units (e.g., a two-step<br />

system would involve a cation vessel and an anion vessel) or a single vessel containing a mixture of<br />

cation and anion exchange resins (mixed bed). Also required in any demineralization system are<br />

appropriate piping, valves, chemical regenerant storage, flow controls, and other accessories properly<br />

engineered for economical balance of resin capacity and chemical efficiency. The following illustrations<br />

show the basic types of demineralization processes and which of the constituents is removed by each of<br />

the demineralizing units.<br />

<strong>DOWEX</strong> <strong>Ion</strong> <strong>Exchange</strong> <strong>Resins</strong> 37 Water Conditioning Manual