DOWEX Ion Exchange Resins WATER CONDITIONING MANUAL

DOWEX Ion Exchange Resins WATER CONDITIONING MANUAL

DOWEX Ion Exchange Resins WATER CONDITIONING MANUAL

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Demineralization (Deionization) Process<br />

7.3.1 Equipment Sizing<br />

See Section 11.7.<br />

Note: CADIX can also be used to perform these calculations.<br />

7.4 Product Water Quality<br />

If it is a process water, it is likely that complete removal of carbon dioxide and silica is unnecessary. If so,<br />

a weak base anion resin is used. If removal of carbon dioxide and silica is required, a strong base anion<br />

resin is chosen. Demineralizers can produce waters with varied quality, depending on the type of system<br />

and the water supply. They usually produce water free of suspended solids. Determination of dissolved<br />

solids by evaporation will include any organic matter that may be present in the deionized water. Water<br />

quality is often measured in terms of the amount of suspended solids, dissolved solids concentration, and<br />

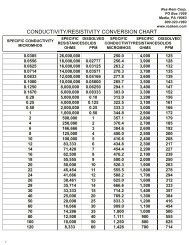

conductivity (µS/cm) or resistivity (MΩ.cm). Since conductivity is the reciprocal of resistivity, 1 µS/cm is<br />

equivalent to 1 MΩ.cm and represents approximately 0.5 ppm. A mixed bed unit is required if water purity<br />

in excess of 5 MΩ.cm is needed. The mixed bed may be the primary unit or a polishing unit following a<br />

multiple bed system.<br />

7.5 Product Water Quantity<br />

Usually, if the water demand is less than approximately 50 gpm (11.4 m 3 /h), the plant will benefit from the<br />

simplest piece of equipment at the expense of a higher chemical operating cost. For that reason, it is<br />

common to find mixed bed demineralizers widely used for small plant requirements because both the<br />

anion and cation resin can be contained in one unit and no degasifier is used. On the other hand, when<br />

plant demands exceed 200 gpm, it is almost certain that several units will be built into the demineralizer<br />

and one will probably be a degasifier.<br />

7.6 Other Demineralization Techniques<br />

The various ion exchange resin combinations indicated in the flow diagrams in Table 11 represent the<br />

majority of system designs employed today. Variations from these standard designs, however, are being<br />

increasingly utilized, especially those techniques that demonstrate significant chemical regenerant<br />

utilization improvements. Two of these techniques are outlined here.<br />

7.6.1 Counter-current Operation<br />

This term refers to the relative flow directions of the service and regeneration cycles. As opposed to the<br />

typical downflow service and regeneration of many systems, counter-current operation is typically<br />

downflow service and upflow regeneration. The primary advantage of counter-current operation is that<br />

very low leakage can be obtained at moderate regeneration levels, thus minimizing operating and waste<br />

disposal costs. Counter-current operation is also advantageous in softening.<br />

7.6.2 Layered Beds<br />

A layered bed of ion exchange resin involves the use of two cation resins or two anion resins in a single<br />

unit. A cation layered bed is composed of a weak acid resin upper layer and a strong acid resin lower<br />

layer, while an anion layered bed uses either a weak base resin upper layer with a strong base resin<br />

lower layer or a strong base resin upper layer and weak base resin lower layer depending on the density<br />

of the resins. In general, the use of layered beds allows some of the advantages of weak acid and weak<br />

base resins to be realized in the operation of a single cation or anion bed. Improved regenerant<br />

efficiencies and, in some cases, improved operating capacities over the corresponding strong acid or<br />

strong base units alone are attained. The layered bed concept is made possible by the density and<br />

particle size differences between the resins used. Upon exhaustion, the backwashing operation separates<br />

the resin layers that may have become partially mixed during service. In order for the full advantages of<br />

the weak acid and weak base resins to be realized, good resin separation is important.<br />

<strong>DOWEX</strong> <strong>Ion</strong> <strong>Exchange</strong> <strong>Resins</strong> 39 Water Conditioning Manual