ENSACO® Conductive Carbon Black for polymer ... - Timcal Graphite

ENSACO® Conductive Carbon Black for polymer ... - Timcal Graphite

ENSACO® Conductive Carbon Black for polymer ... - Timcal Graphite

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

10<br />

The selection of a<br />

conductive carbon black<br />

NENSACO ® <strong>Conductive</strong> <strong>Carbon</strong> <strong>Black</strong>s find<br />

their applications in an unlimited number of<br />

plastics. The combination of the <strong>polymer</strong> type<br />

and grade and the carbon black grade are determining<br />

the overall electrical and mechanical<br />

per<strong>for</strong>mance.<br />

NThe main parameter influencing the final<br />

conductivity of a finished part in a given <strong>polymer</strong><br />

is the type and level of carbon black used.<br />

NThe higher the structure of the carbon black,<br />

the lower the level of carbon black needed to<br />

achieve the required conductivity. Nevertheless,<br />

in a minor way, other parameters like the additives<br />

in presence, the compounding or processing<br />

conditions may also influence the final conductivity<br />

of parts.<br />

NLow surface area conductive carbon blacks<br />

show a particular advantage on dispersion and<br />

processing.<br />

NPercolation curves – correlating the volume<br />

resistivity and the carbon black percentage – are<br />

a useful comparative tool to predict the conductivity<br />

in place and to select the more appropriate<br />

system. These curves are valid <strong>for</strong> a given <strong>for</strong>mulation<br />

and sample preparation technique.<br />

NThe selection of the conductive carbon black<br />

will also influence:<br />

the compounding behaviour<br />

(dispersibility, resistance to shear, mixing cycle,<br />

melt flow index, extrusion throughput);<br />

the surface appearance of the finished<br />

material (number of surface defects);<br />

the mechanical properties<br />

(<strong>polymer</strong> property retention, rein<strong>for</strong>cement);<br />

the overall price – per<strong>for</strong>mance ratio.<br />

www.timcal.com<br />

Typical applications <strong>for</strong> ENSACO ® <strong>Conductive</strong> <strong>Carbon</strong> <strong>Black</strong><br />

Electrically<br />

conductive plastics<br />

The preparation of a<br />

conductive compound<br />

NSuitable mixing equipments <strong>for</strong> the preparation<br />

of black conductive compounds include<br />

internal mixers, twin screw extruders, single<br />

screw kneader machines and LCM. The feeding<br />

of low bulk density, soft flake-type carbon<br />

blacks into extruders requires the use of twin<br />

screw feeders and separate introduction on an<br />

already molten <strong>polymer</strong> (split feeding technology).<br />

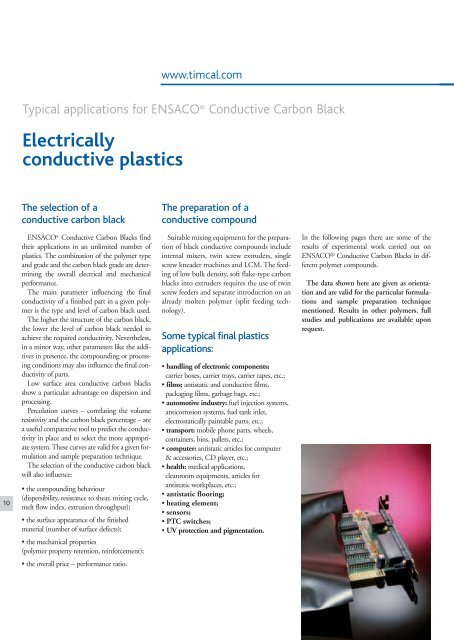

Some typical final plastics<br />

applications:<br />

handling of electronic components:<br />

carrier boxes, carrier trays, carrier tapes, etc.;<br />

films: antistatic and conductive films,<br />

packaging films, garbage bags, etc.;<br />

automotive industry: fuel injection systems,<br />

anticorrosion systems, fuel tank inlet,<br />

electrostatically paintable parts, etc.;<br />

transport: mobile phone parts, wheels,<br />

containers, bins, pallets, etc.;<br />

computer: antistatic articles <strong>for</strong> computer<br />

& accessories, CD player, etc.;<br />

health: medical applications,<br />

cleanroom equipments, articles <strong>for</strong><br />

antistatic workplaces, etc.;<br />

antistatic flooring;<br />

heating element;<br />

sensors;<br />

PTC switches;<br />

UV protection and pigmentation.<br />

In the following pages there are some of the<br />

results of experimental work carried out on<br />

ENSACO ® <strong>Conductive</strong> <strong>Carbon</strong> <strong>Black</strong>s in different<br />

<strong>polymer</strong> compounds.<br />

The data shown here are given as orientation<br />

and are valid <strong>for</strong> the particular <strong>for</strong>mulations<br />

and sample preparation technique<br />

mentioned. Results in other <strong>polymer</strong>s, full<br />

studies and publications are available upon<br />

request.