ENSACO® Conductive Carbon Black for polymer ... - Timcal Graphite

ENSACO® Conductive Carbon Black for polymer ... - Timcal Graphite

ENSACO® Conductive Carbon Black for polymer ... - Timcal Graphite

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

18<br />

Self lubricating<br />

<strong>polymer</strong>s<br />

NThe choice of a <strong>polymer</strong>-based self lubricating<br />

solid <strong>for</strong> a particular application depends<br />

mainly upon the operating conditions of:<br />

temperature, chemical environment and the<br />

maximum values of pressure (p) and sliding<br />

speed (v). For each <strong>polymer</strong> or composite<br />

material, a pv limit is quoted, which corresponds<br />

to the pressure times the sliding speed<br />

at which the material fails, either due to unacceptable<br />

de<strong>for</strong>mation, or to the high frictional<br />

energy dissipated causes surface melting,<br />

softening and excessive wear.<br />

NThe pv limit of a <strong>polymer</strong>ic material may<br />

be increased by increasing its mechanical<br />

strength (resistance to de<strong>for</strong>mation), thermal<br />

conductivity (reduction in surface temperatures)<br />

and by decreasing friction (reduces frictional<br />

heating). In practice, thermoplastics<br />

(with the exception of PTFE) are mainly used<br />

as pure solids, since their wear resistance and<br />

frictional coefficient, are satisfactory <strong>for</strong><br />

most applications. Solid lubricant fillers or<br />

fibre rein<strong>for</strong>cement (glass fibres, carbon<br />

fibres, textiles) are only employed under the<br />

more extreme conditions of load and speed.<br />

NThe major <strong>polymer</strong>s employed as self lubricating<br />

solids/composites, are illustrated<br />

below.<br />

www.timcal.com<br />

Typical applications <strong>for</strong> TIMREX® <strong>Graphite</strong> and Coke<br />

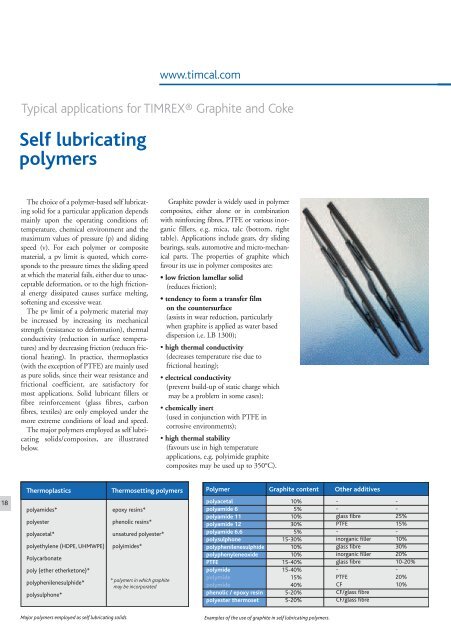

Thermoplastics Thermosetting <strong>polymer</strong>s<br />

polyamides*<br />

polyester<br />

polyacetal*<br />

polyethylene (HDPE, UHMWPE)<br />

Polycarbonate<br />

poly (ether etherketone)*<br />

polyphenilenesulphide*<br />

polysulphone*<br />

epoxy resins*<br />

phenolic resins*<br />

unsatured polyester*<br />

polyimides*<br />

Major <strong>polymer</strong>s employed as self lubricating solids.<br />

* <strong>polymer</strong>s in which graphite<br />

may be incorporated<br />

N <strong>Graphite</strong> powder is widely used in <strong>polymer</strong><br />

composites, either alone or in combination<br />

with rein<strong>for</strong>cing fibres, PTFE or various inorganic<br />

fillers, e.g. mica, talc (bottom, right<br />

table). Applications include gears, dry sliding<br />

bearings, seals, automotive and micro-mechanical<br />

parts. The properties of graphite which<br />

favour its use in <strong>polymer</strong> composites are:<br />

low friction lamellar solid<br />

(reduces friction);<br />

tendency to <strong>for</strong>m a transfer film<br />

on the countersurface<br />

(assists in wear reduction, particularly<br />

when graphite is applied as water based<br />

dispersion i.e. LB 1300);<br />

high thermal conductivity<br />

(decreases temperature rise due to<br />

frictional heating);<br />

electrical conductivity<br />

(prevent build-up of static charge which<br />

may be a problem in some cases);<br />

chemically inert<br />

(used in conjunction with PTFE in<br />

corrosive environments);<br />

high thermal stability<br />

(favours use in high temperature<br />

applications, e.g. polyimide graphite<br />

composites may be used up to 350°C).<br />

Polymer <strong>Graphite</strong> content Other additives<br />

polyacetal<br />

polyamide 6<br />

polyamide 11<br />

polyamide 12<br />

polyamide 6.6<br />

polysulphone<br />

polyphenilenesulphide<br />

polyphenyleneoxide<br />

PTFE<br />

polymide<br />

polymide<br />

polymide<br />

phenolic / epoxy resin<br />

polyester thermoset<br />

10%<br />

5%<br />

10%<br />

30%<br />

5%<br />

15-30%<br />

10%<br />

10%<br />

15-40%<br />

15-40%<br />

15%<br />

40%<br />

5-20%<br />

5-20%<br />

Examples of the use of graphite in self lubricating <strong>polymer</strong>s.<br />

-<br />

-<br />

glass fibre<br />

PTFE<br />

-<br />

inorganic filler<br />

glass fibre<br />

inorganic filler<br />

glass fibre<br />

-<br />

PTFE<br />

CF<br />

CF/glass fibre<br />

CF/glass fibre<br />

-<br />

-<br />

25%<br />

15%<br />

-<br />

10%<br />

30%<br />

20%<br />

10-20%<br />

-<br />

20%<br />

10%