ENSACO® Conductive Carbon Black for polymer ... - Timcal Graphite

ENSACO® Conductive Carbon Black for polymer ... - Timcal Graphite

ENSACO® Conductive Carbon Black for polymer ... - Timcal Graphite

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

12<br />

www.timcal.com<br />

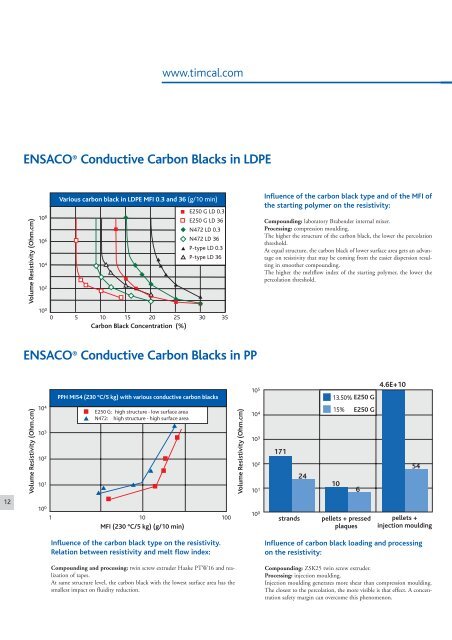

ENSACO ® <strong>Conductive</strong> <strong>Carbon</strong> <strong>Black</strong>s in LDPE<br />

Volume Resistivity (Ohm.cm)<br />

Volume Resistivity (Ohm.cm)<br />

10 8<br />

10 6<br />

10 4<br />

10 2<br />

10 0<br />

10 4<br />

10 3<br />

10 2<br />

10 1<br />

10 0<br />

Various carbon black in LDPE MFI 0.3 and 36 (g/10 min)<br />

E250 G LD 0.3<br />

E250 G LD 36<br />

N472 LD 0.3<br />

N472 LD 36<br />

P-type LD 0.3<br />

P-type LD 36<br />

0 5 10 15 20 25 30 35<br />

<strong>Carbon</strong> <strong>Black</strong> Concentration (%)<br />

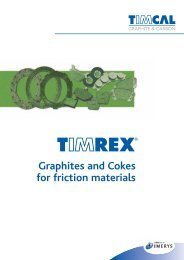

ENSACO ® <strong>Conductive</strong> <strong>Carbon</strong> <strong>Black</strong>s in PP<br />

PPH MI54 (230 °C/5 kg) with various conductive carbon blacks<br />

E250 G: high structure - low surface area<br />

N472: high structure - high surface area<br />

1 10<br />

MFI (230 °C/5 kg) (g/10 min)<br />

100<br />

Influence of the carbon black type on the resistivity.<br />

Relation between resistivity and melt flow index:<br />

Compounding and processing: twin screw extruder Haake PTW16 and realization<br />

of tapes.<br />

At same structure level, the carbon black with the lowest surface area has the<br />

smallest impact on fluidity reduction.<br />

Volume Resistivity (Ohm.cm)<br />

10 5<br />

10 4<br />

10 3<br />

10 2<br />

10 1<br />

10 0<br />

Influence of the carbon black type and of the MFI of<br />

the starting <strong>polymer</strong> on the resistivity:<br />

Compounding: laboratory Brabender internal mixer.<br />

Processing: compression moulding.<br />

The higher the structure of the carbon black, the lower the percolation<br />

threshold.<br />

At equal structure, the carbon black of lower surface area gets an advantage<br />

on resistivity that may be coming from the easier dispersion resulting<br />

in smoother compounding.<br />

The higher the meltflow index of the starting <strong>polymer</strong>, the lower the<br />

percolation threshold.<br />

171<br />

24<br />

13.50% E250 G<br />

15% E250 G<br />

10<br />

strands pellets + pressed<br />

plaques<br />

6<br />

4.6E+10<br />

54<br />

pellets +<br />

injection moulding<br />

Influence of carbon black loading and processing<br />

on the resistivity:<br />

Compounding: ZSK25 twin screw extruder.<br />

Processing: injection moulding.<br />

Injection moulding generates more shear than compression moulding.<br />

The closest to the percolation, the more visible is that effect. A concentration<br />

safety margin can overcome this phenomenon.