ENSACO® Conductive Carbon Black for polymer ... - Timcal Graphite

ENSACO® Conductive Carbon Black for polymer ... - Timcal Graphite

ENSACO® Conductive Carbon Black for polymer ... - Timcal Graphite

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Introduction to TIMREX ®<br />

<strong>Graphite</strong> and Coke<br />

N<strong>Graphite</strong> finds wide application because<br />

of its favourable combination of properties.<br />

These include:<br />

low friction, chemical inertness<br />

and absence of inherent abrasiveness;<br />

high thermal conductivity, thermal<br />

stability and electrical conductivity;<br />

film <strong>for</strong>ming ability on metal surfaces;<br />

relatively inoffensive nature of both<br />

Npowders and products of combustion.<br />

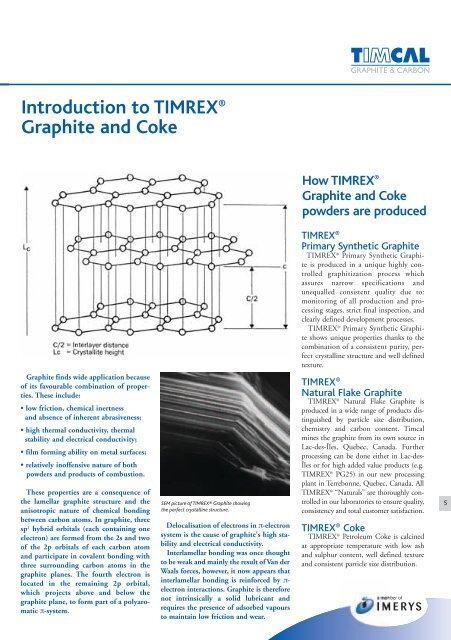

NThese properties are a consequence of<br />

the lamellar graphite structure and the<br />

anisotropic nature of chemical bonding<br />

between carbon atoms. In graphite, three<br />

sp 2 hybrid orbitals (each containing one<br />

electron) are <strong>for</strong>med from the 2s and two<br />

of the 2p orbitals of each carbon atom<br />

and participate in covalent bonding with<br />

three surrounding carbon atoms in the<br />

graphite planes. The fourth electron is<br />

located in the remaining 2p orbital,<br />

which projects above and below the<br />

graphite plane, to <strong>for</strong>m part of a polyaromatic<br />

π-system.<br />

SEM picture of TIMREX® <strong>Graphite</strong> showing<br />

the perfect crystalline structure.<br />

NDelocalisation of electrons in π-electron<br />

system is the cause of graphite's high stability<br />

and electrical conductivity.<br />

Interlamellar bonding was once thought<br />

to be weak and mainly the result of Van der<br />

Waals <strong>for</strong>ces, however, it now appears that<br />

interlamellar bonding is rein<strong>for</strong>ced by πelectron<br />

interactions. <strong>Graphite</strong> is there<strong>for</strong>e<br />

not intrinsically a solid lubricant and<br />

requires the presence of adsorbed vapours<br />

to maintain low friction and wear.<br />

How TIMREX ®<br />

<strong>Graphite</strong> and Coke<br />

powders are produced<br />

TIMREX ®<br />

Primary Synthetic <strong>Graphite</strong><br />

TIMREX ® Primary Synthetic <strong>Graphite</strong><br />

is produced in a unique highly controlled<br />

graphitization process which<br />

assures narrow specifications and<br />

unequalled consistent quality due to:<br />

monitoring of all production and processing<br />

stages, strict final inspection, and<br />

clearly defined development processes.<br />

TIMREX ® Primary Synthetic <strong>Graphite</strong><br />

shows unique properties thanks to the<br />

combination of a consistent purity, perfect<br />

crystalline structure and well defined<br />

texture.<br />

TIMREX ®<br />

Natural Flake <strong>Graphite</strong><br />

TIMREX ® Natural Flake <strong>Graphite</strong> is<br />

produced in a wide range of products distinguished<br />

by particle size distribution,<br />

chemistry and carbon content. <strong>Timcal</strong><br />

mines the graphite from its own source in<br />

Lac-des-Îles, Quebec, Canada. Further<br />

processing can be done either in Lac-des-<br />

Îles or <strong>for</strong> high added value products (e.g.<br />

TIMREX ® PG25) in our new processing<br />

plant in Terrebonne, Quebec, Canada. All<br />

TIMREX ® “Naturals” are thoroughly controlled<br />

in our laboratories to ensure quality,<br />

consistency and total customer satisfaction.<br />

TIMREX ® Coke<br />

TIMREX ® Petroleum Coke is calcined<br />

at appropriate temperature with low ash<br />

and sulphur content, well defined texture<br />

and consistent particle size distribution.<br />

5