ENSACO® Conductive Carbon Black for polymer ... - Timcal Graphite

ENSACO® Conductive Carbon Black for polymer ... - Timcal Graphite

ENSACO® Conductive Carbon Black for polymer ... - Timcal Graphite

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

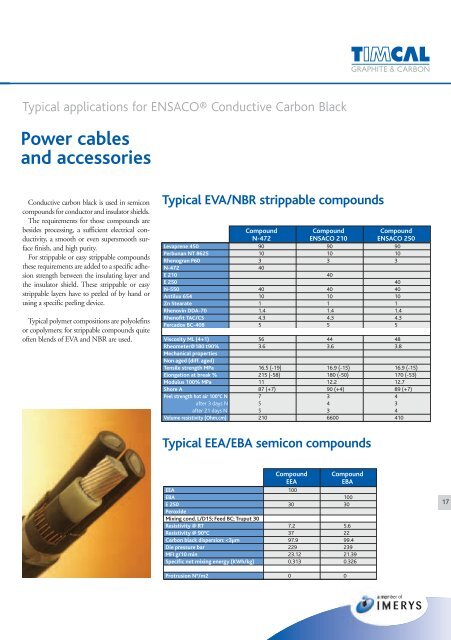

Typical applications <strong>for</strong> <strong>ENSACO®</strong> <strong>Conductive</strong> <strong>Carbon</strong> <strong>Black</strong><br />

Power cables<br />

and accessories<br />

N<strong>Conductive</strong> carbon black is used in semicon<br />

compounds <strong>for</strong> conductor and insulator shields.<br />

NThe requirements <strong>for</strong> those compounds are<br />

besides processing, a sufficient electrical conductivity,<br />

a smooth or even supersmooth surface<br />

finish, and high purity.<br />

NFor strippable or easy strippable compounds<br />

these requirements are added to a specific adhesion<br />

strength between the insulating layer and<br />

the insulator shield. These strippable or easy<br />

strippable layers have to peeled of by hand or<br />

using a specific peeling device.<br />

NTypical <strong>polymer</strong> compositions are polyolefins<br />

or co<strong>polymer</strong>s; <strong>for</strong> strippable compounds quite<br />

often blends of EVA and NBR are used.<br />

Typical EVA/NBR strippable compounds<br />

Levaprene 450<br />

Perbunan NT 8625<br />

Rhenogran P60<br />

N-472<br />

E 210<br />

E 250<br />

N-550<br />

Antilux 654<br />

Zn Stearate<br />

Rhenovin DDA-70<br />

Rhenofit TAC/CS<br />

Percadox BC-408<br />

Viscosity ML (4+1)<br />

Rheometer@180 t90%<br />

Mechanical properties<br />

Non aged (diff. aged)<br />

Tensile strength MPa<br />

Elongation at break %<br />

Modulus 100% MPa<br />

Shore A<br />

Peel strength hot air 100°C N<br />

after 3 days N<br />

after 21 days N<br />

Volume resistivity (Ohm.cm)<br />

Compound<br />

N-472<br />

90<br />

10<br />

3<br />

40<br />

40<br />

10<br />

1<br />

1.4<br />

4.3<br />

5<br />

56<br />

3.6<br />

16.5 (-19)<br />

215 (-58)<br />

11<br />

87 (+7)<br />

7<br />

5<br />

5<br />

210<br />

Compound<br />

ENSACO 210<br />

90<br />

10<br />

3<br />

40<br />

40<br />

10<br />

1<br />

1.4<br />

4.3<br />

5<br />

44<br />

3.6<br />

16.9 (-15)<br />

180 (-50)<br />

12.2<br />

90 (+4)<br />

3<br />

4<br />

3<br />

6600<br />

Typical EEA/EBA semicon compounds<br />

EEA<br />

EBA<br />

E 250<br />

Peroxide<br />

Mixing cond. L/D15; Feed BC; Truput 30<br />

Resistivity @ RT<br />

Resistivity @ 90°C<br />

<strong>Carbon</strong> black dispersion: