Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

worldmags<br />

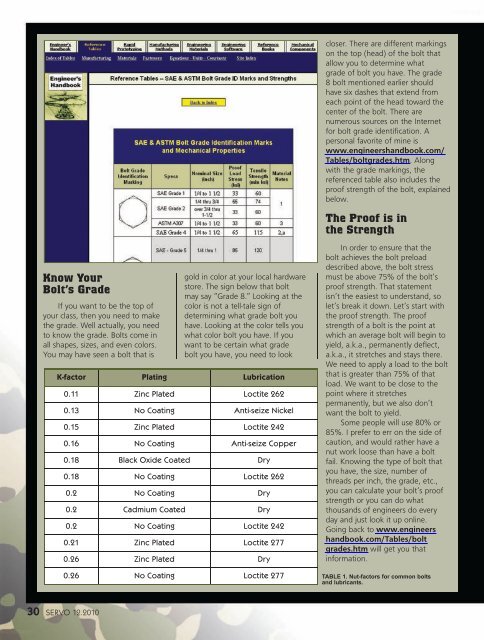

Know Your<br />

Bolt’s Grade<br />

If you want to be the top of<br />

your class, then you need to make<br />

the grade. Well actually, you need<br />

to know the grade. Bolts come in<br />

all shapes, sizes, <strong>and</strong> even colors.<br />

You may have seen a bolt that is<br />

30 SERVO 12.2010<br />

gold in color at your local hardware<br />

store. The sign below that bolt<br />

may say “Grade 8.” Looking at the<br />

color is not a tell-tale sign of<br />

determining what grade bolt you<br />

have. Looking at the color tells you<br />

what color bolt you have. If you<br />

want to be certain what grade<br />

bolt you have, you need to look<br />

K-factor Plating Lubrication<br />

0.11 Zinc Plated Loctite 262<br />

0.13 No Coating Anti-seize Nickel<br />

0.15 Zinc Plated Loctite 242<br />

0.16 No Coating Anti-seize Copper<br />

0.18 Black Oxide Coated Dry<br />

0.18 No Coating Loctite 262<br />

0.2 No Coating Dry<br />

0.2 Cadmium Coated Dry<br />

0.2 No Coating Loctite 242<br />

0.21 Zinc Plated Loctite 277<br />

0.26 Zinc Plated Dry<br />

closer. There are different markings<br />

on the top (head) of the bolt that<br />

allow you to determine what<br />

grade of bolt you have. The grade<br />

8 bolt mentioned earlier should<br />

have six dashes that extend from<br />

each point of the head toward the<br />

center of the bolt. There are<br />

numerous sources on the Internet<br />

for bolt grade identification. A<br />

personal favorite of mine is<br />

www.engineersh<strong>and</strong>book.com/<br />

Tables/boltgrades.htm. Along<br />

with the grade markings, the<br />

referenced table also includes the<br />

proof strength of the bolt, explained<br />

below.<br />

The Proof is in<br />

the Strength<br />

In order to ensure that the<br />

bolt achieves the bolt preload<br />

described above, the bolt stress<br />

must be above 75% of the bolt’s<br />

proof strength. That statement<br />

isn’t the easiest to underst<strong>and</strong>, so<br />

let’s break it down. Let’s start with<br />

the proof strength. The proof<br />

strength of a bolt is the point at<br />

which an average bolt will begin to<br />

yield, a.k.a., permanently deflect,<br />

a.k.a., it stretches <strong>and</strong> stays there.<br />

We need to apply a load to the bolt<br />

that is greater than 75% of that<br />

load. We want to be close to the<br />

point where it stretches<br />

permanently, but we also don’t<br />

want the bolt to yield.<br />

Some people will use 80% or<br />

85%. I prefer to err on the side of<br />

caution, <strong>and</strong> would rather have a<br />

nut work loose than have a bolt<br />

fail. Knowing the type of bolt that<br />

you have, the size, number of<br />

threads per inch, the grade, etc.,<br />

you can calculate your bolt’s proof<br />

strength or you can do what<br />

thous<strong>and</strong>s of engineers do every<br />

day <strong>and</strong> just look it up online.<br />

Going back to www.engineers<br />

h<strong>and</strong>book.com/Tables/bolt<br />

grades.htm will get you that<br />

information.<br />

0.26 No Coating Loctite 277 TABLE 1. Nut-factors for common bolts<br />

<strong>and</strong> lubricants.<br />

worldmags