Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

worldmags<br />

PWM(), respectively. Examining these methods, you would<br />

notice they each have an infinite loop that would never<br />

finish. Quad continuously monitors <strong>and</strong> updates the<br />

quadrature state count, <strong>and</strong> PWM() ensures the PWM<br />

signal is constantly updated.<br />

In traditional interrupt or event-driven programming,<br />

these loops would have to be “interrupted” occasionally to<br />

allow for the rest of the program to execute. Also, since<br />

they would be running together you wouldn’t be able to<br />

put them in two separate loops like we have them now.<br />

Furthermore, due to the interruptions their actions would<br />

not be fully deterministic, meaning that the system may<br />

have signaling jitter <strong>and</strong> missed pulse counts while other<br />

tasks are being h<strong>and</strong>led by the processor.<br />

In the Propeller chip, these two methods run fully in<br />

parallel in their own cogs eliminating the need for<br />

interrupts. Notice the statements that call CogNew() in the<br />

Start() methods in both figures. This function launches the<br />

associated method (subroutine) into one of the eight cogs.<br />

Once a cog is started, it will continuously do its tasks<br />

independently of other cogs. However, notice how in<br />

Figure 11 the PWM duty level is set. This is the way to<br />

communicate between the cog that is<br />

running the main program <strong>and</strong> the cog that<br />

carries out the PWM work. We just set a<br />

value within the hub RAM which PWM()<br />

knows about <strong>and</strong> can read. Upon reading<br />

this value, it will change the duty level of the<br />

PWM signal.<br />

Likewise, the quadrature encoder cog<br />

will continue to interrogate the infrared<br />

hardware <strong>and</strong> update the state count into a<br />

variable in the hub RAM. The cog running<br />

the main program reads this count when<br />

needed from that variable.<br />

We do not have to worry about<br />

contention h<strong>and</strong>ling because the Propeller<br />

chip does that for us by ensuring that each<br />

cog can only read or write to the hub RAM<br />

in a round robin fashion. This guarantees<br />

that no two cogs can simultaneously read<br />

<strong>and</strong> write to the shared memory.<br />

The round robin contention prevention<br />

works on a long (32 bits) by long basis.<br />

Should you need to ensure exclusive access<br />

to a block of memory over multiple round<br />

robin turns, the Propeller chip also provides<br />

hardware-based semaphores (eight of them,<br />

called locks) which simplify semaphore<br />

programming tremendously. In our programs,<br />

we do not need them since we are only<br />

using longs for the PWM duty <strong>and</strong> the<br />

quadrature state count.<br />

Putting A Fresh Spin<br />

On Things<br />

The RobotBASIC program was necessary<br />

in the original project because we needed a GUI for the<br />

operator of the system to be able to comm<strong>and</strong> it.<br />

Additionally, the simulator aspect was powerful for the<br />

purposes of operator training <strong>and</strong> for tweaking system<br />

parameters like PID factors. With the Propeller-based<br />

project, you are able to dispense with the PC system (with a<br />

caveat).<br />

With the Propeller chip <strong>and</strong> a few pre-written powerful<br />

objects <strong>and</strong> some resistors, you can add a PS/2 mouse <strong>and</strong><br />

keyboard, as well as a VGA (or TV) display to the system.<br />

The Propeller can also do floating point math (using an<br />

object) which would enable the implementation of an<br />

accurate PID control algorithm. You can therefore<br />

implement the user interface for the operator, as well as<br />

the PID control using just the Propeller chip.<br />

This is definitely a powerful option, but the graphics<br />

<strong>and</strong> GUI are not going to be as powerful as you can<br />

achieve on a PC. Also, a PC system can provide additional<br />

processing <strong>and</strong> other services that can enhance a Propellerbased<br />

project (e.g., the simulator in this project). SV<br />

www.servomagazine.com/index.php?/magazine/article/<br />

december2010_Blankenship<br />

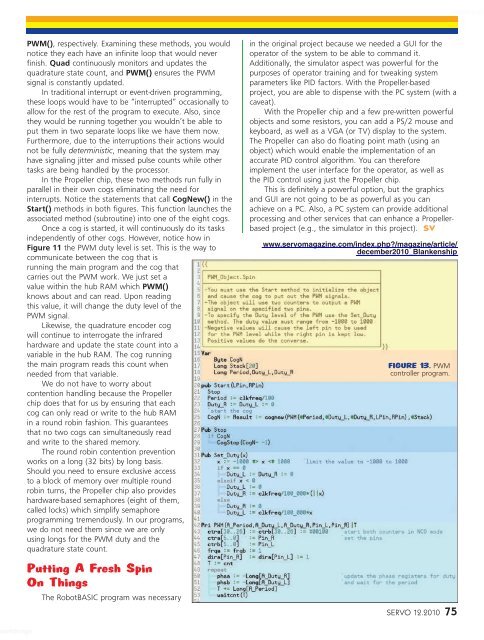

FIGURE 13. PWM<br />

controller program.<br />

SERVO 12.2010 75<br />

worldmags