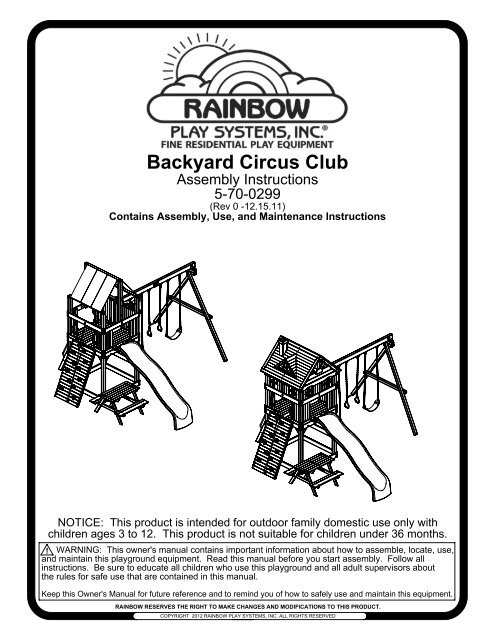

Backyard Circus Club

Backyard Circus Club

Backyard Circus Club

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Backyard</strong> <strong>Circus</strong> <strong>Club</strong><br />

Assembly Instructions<br />

5-70-0299<br />

(Rev 0 -12.15.11)<br />

Contains Assembly, Use, and Maintenance Instructions<br />

NOTICE: This product is intended for outdoor family domestic use only with<br />

children ages 3 to 12. This product is not suitable for children under 36 months.<br />

! WARNING: This owner's manual contains important information about how to assemble, locate, use,<br />

and maintain this playground equipment. Read this manual before you start assembly. Follow all<br />

instructions. Be sure to educate all children who use this playground and all adult supervisors about<br />

the rules for safe use that are contained in this manual.<br />

Keep this Owner's Manual for future reference and to remind you of how to safely use and maintain this equipment.<br />

RAINBOW RESERVES THE RIGHT TO MAKE CHANGES AND MODIFICATIONS TO THIS PRODUCT.<br />

COPYRIGHT 2012 RAINBOW PLAY SYSTEMS, INC. ALL RIGHTS RESERVED

OWNER'S MANUAL<br />

Rainbow Play Systems, Inc.<br />

Thank you for choosing Rainbow Play Systems, Inc. For your and your<br />

children's safety, please read the instruction manual thoroughly before<br />

you start building your Rainbow Play Systems, Inc. playground.<br />

Familiarize yourself with all hardware and parts to help with building your<br />

playground.<br />

WARNING: Failure to follow the assembly, location, use, and<br />

maintenance instructions in this manual could result<br />

in serious injury to children using this playground.<br />

Rules for Safe Play..........................................................................2<br />

Choosing Location of Play System..................................................3<br />

Choosing Proper Surface Material...................................................3-4<br />

Maintenance....................................................................................4<br />

Helpful Tips.....................................................................................5<br />

Commonly Asked Questions...........................................................6<br />

Parts Identification...........................................................................7-15<br />

Hardware.........................................................................................16-19<br />

Tools Required for Assembly..........................................................19<br />

Instructions......................................................................................20-52<br />

Warranty..........................................................................................53<br />

1

Thoroughly read all Safety Instructions on pages 2-5 before beginning assembly of<br />

your playset.<br />

Welcome to RAINBOW<br />

Welcome to our family of ready-to-build residential play equipment. Ease of assembly has been pre-engineered into<br />

our product and we provide step-by-step installation instructions.<br />

To ensure safe play for your children, before building your play system, please take some time with your children and<br />

go over the Rules for safe play on your play system. Do not allow children in the area while you are assembling<br />

your play system. Many of Rainbow's components are very heavy and could seriously injure a child. Observing these<br />

rules reduces the likelihood of serious or fatal injury.<br />

After thoroughly reading the information below, locate your play site and carefully unpack parts. As you<br />

unpack your play system, keep the parts list handy and become familiar with each part before beginning assembly.<br />

Remember that a little extra time spent familiarizing yourself with the parts and the instructions before you begin will<br />

help to avoid mistakes and save you time later. Please keep these instructions for future reference.<br />

This product is recommended for children 3 to 12 years of age.<br />

Note: This product is not intended for public use. Rainbow Play Systems, Inc. does not<br />

warranty its Residential Play Equipment subject to commercial use.<br />

Safety Instructions<br />

Rules for Safe Play<br />

WARNING: Before allowing children to play on this equipment for the first time, carefully review<br />

the rules for safe play with them. Observing the following statements and warnings<br />

reduces the likelihood of a serious or fatal injury.<br />

1. IT IS RECOMMENDED that no more than 6-8 children, not exceeding a combined weight of 1,200 pounds, play on the<br />

system at one time. This product is recommended for children 3 to 12 years of age.<br />

2. CLOSE ADULT SUPERVISION is required for children of all ages.<br />

3. WARN CHILDREN TO AVOID playing or walking in front of, behind, or between moving equipment.<br />

4. WARN CHILDREN NOT TO twist swing chains or ropes, or to loop them over the top support bar since this may reduce the<br />

strength of the chain or rope.<br />

5. INSTRUCT CHILDREN NOT TO swing empty seats, trapeze bar, gliders, buoy balls or tire swings.<br />

6. INSTRUCT CHILDREN to always sit, never stand or kneel, in the center of the swing seat with their full weight.<br />

7. INSTRUCT CHILDREN NOT TO use any part of the play system in a manner other than what it is intended.<br />

8. INSTRUCT CHILDREN NOT TO get off equipment while it is in motion.<br />

9. DRESS CHILDREN APPROPRIATELY. CHILDREN SHOULD NOT wear scarves, hats with straps, helmets, jackets with<br />

draw strings, hooded jackets, poorly fitting shoes, or any other loose fitting clothing that is potentially hazardous while<br />

using equipment.<br />

10. INSTRUCT CHILDREN NOT TO play on the equipment if it is wet. Potentially slippery surfaces may cause a hazard.<br />

11. VERIFY all suspended items such as ropes and chains are secure at both ends.<br />

12. VERIFY all suspended items such as climbing ropes are tight so they cannot be looped back on themselves.<br />

13. INSTRUCT CHILDREN NOT TO attach items to the play system not specifically intended for use with the play equipment.<br />

Items such as, but not limited to, jump ropes, clotheslines, pet leashes, cables and chain may pose a strangulation hazard.<br />

14. INSTRUCT CHILDREN TO REMOVE any bike or other sports helmets before playing on the play equipment, as they may<br />

pose a possible hanging hazard. Children must be dressed appropriately.<br />

15. INSTRUCT CHILDREN there may only be one person on a swing at a time with a maximum weight of 150 pounds per swing.<br />

16. VERIFY there are no gaps between the slide bed way and the slide screws.<br />

17. INSTRUCT CHILDREN to always go down slides feet first. Never slide head first.<br />

18. INSTRUCT CHILDREN TO NEVER climb, crawl, or walk on items not intended for such use. Such types of play on top of<br />

Monkey Bars, Fort Roof, and Swing Beams greatly increase the risk of a serious or fatal fall.<br />

2

Choosing a location for your play system<br />

When selecting your play site, always keep the child's safety in mind. Here are some recommendations that should help you achieve a safe<br />

play area.<br />

1. The play system should be located on solid level ground free of objects that could cause injury such as, but not limited to, tree stumps,<br />

roots, and large rocks. Stationary components such as ladders and slides must be no less than SIX FEET (1.8 meters) from any<br />

structure or obstruction such as a fence, garage, house, tree or overhanging branches, electrical wires or clotheslines. Any swinging<br />

equipment must be a minimum distance of TWICE the height of the swing beam away from any structures or obstructions as specified<br />

above. We also recommend that you do not install your play system near a lake, river, swimming pool or other water hazards.<br />

2. If anchoring your play system, all underground utilities must be located in play zone before starting assembly of play system.<br />

3. Try to locate slide out of direct sunlight to reduce the likelihood of serious burns. A slide that faces north will receive the least direct<br />

sunlight.<br />

4. It is recommended not to place a set on sandy soil or loose fill as it may require additional anchoring in that situation.<br />

5. Do not install your play system over concrete, asphalt, packed earth, grass, carpet, or any other hard surface. A fall onto a hard surface<br />

can result in serious injury to the play system user.<br />

Set Dimensions Play Zone<br />

L 15 1/2' x W 15' x<br />

H 11'<br />

L 27 1/2' x W 30 1/2'<br />

6' min.<br />

6' min. 6' min.<br />

6' min.<br />

2x Swing<br />

Beam Height<br />

2x Swing<br />

Beam Height<br />

Choosing a surfacing material<br />

The consumer shall provide playground surfacing materials under and around residential play equipment that conforms to the<br />

recommendations of the Consumer Product Safety Commission's Outdoor Home Playground Safety Handbook publications #324. A copy<br />

of the section relating to surfacing materials is included in the installation instructions. Free copies of this handbook are available on line at<br />

www.cpsc.gov or by contacting the CPSC Publications Office in Washington D.C. 20207.<br />

The URL is http://www.cpsc.gov/cpscpub/pubs/324.pdf and the file size is 456.5KB<br />

Playground equipment should never be placed on hard surfaces such as concrete or asphalt. Do not use loose fill surfacing on top of hard<br />

surfaces such as concrete or asphalt. While grass may appear to be acceptable, it may quickly turn to hard packed earth in areas of high<br />

traffic. Shredded bark mulch, wood chips, fine sand or fine gravel are considered to be acceptable shock absorbing surfaces when installed<br />

and maintained at a sufficient depth under and around playground equipment. The U.S. Product Safety Commission (CPSC) estimates that<br />

about 100,000 playground equipment-related injuries resulting from falls to the ground surface are treated annually in U.S. hospital's<br />

emergency rooms. Injuries involving this hazard pattern tend to be the most serious of all playground injuries, and have a potential to be<br />

fatal, particularly when the injury is to the head. The surface under and around playground equipment can be a major factor in determining<br />

the injury-causing potential of a fall. It is self evident that a fall onto a shock absorbing surface is less likely to cause a serious injury than a<br />

fall onto a hard surface.<br />

The following information is intended to assist in comparing the relative shock-absorbing properties of various materials. No particular<br />

material is recommended over another. However, each material is only effective when properly maintained. Materials should be checked<br />

periodically and replenished to maintain correct depth as determined necessary for your equipment. The choice of a material depends on<br />

the type and height of your playground equipment, the availability of the material in your area, and its cost.<br />

Table 3.1 lists the maximum height from which a child would not be expected to sustain a life-threatening head injury in a fall onto four<br />

different loose-fill surfacing materials if they are installed and maintained at depths of 6, 9, and 12 inches. However, it should be recognized<br />

that all injuries due to falls cannot be prevented no matter what surfacing material is used.<br />

3

TABLE 3.1 Fall Height in Feet From Which a Life Threatening Head Injury Would Not Be Expected<br />

Type of Material 6 in. depth 9 in. depth 12 in. depth<br />

Double Shredded Bark Mulch 6 ft. 10 ft. 11 ft.<br />

Wood Chips 6 ft. 7 ft. 12 ft.<br />

Fine Sand 5 ft. 5 ft. 9 ft.<br />

Fine Gravel 6 ft. 7 ft. 10 ft.<br />

Surfacing in "compressed" depths - See CPS & ASTM for Fall Heights of equipment<br />

Equipment Fall Height 1' 2' 3' 4' 5' 6' 7' 8' 9' 10' 11' 12'<br />

Wood Chips 6" 6" 6" 6" 6" 6" 6 1/2" 7 1/2" 8 1/4" 9" 12" 13"<br />

Double Shredded Bark Mulch 6" 6" 6" 6" 7" 8" 9" 9 3/4" 10 1/2" 11 1/2" 12" 13"<br />

Engineered Wood Fibers 6" 6" 6" 7" 8 1/2" 9" 9 1/2" 10 1/4" 10 3/4" 11" 10 3/4" 12"<br />

Fine Sand 6" 6" 6 1/2" 8" 9 10" 10 1/2" 11 1/4" 12" 13 1/2" 14 3/4" 16"<br />

Coarse Sand 6" 6" 7 1/2" 9" 10 1/2" 12" 14" 16" 18" 20" 22" 24"<br />

Fine Gravel 6" 6" 6" 6 3/4" 8" 9" 10" 10 3/4" 11 1/2" 12" 13 1/4" 14 1/2"<br />

Medium Gravel 6" 6 1/4" 8" 9" 9" 12" 14" 16" 18" 20" 22" 24"<br />

Chart obtained from U.S. Consumer Product Safety Commission Handbook for Public Playground Safety<br />

NOTICE: It is recommended to use containment, such as digging out around the perimeter and/or lining the perimeter with<br />

landscape edging for surfacing materials.<br />

Installations of rubber tiles or poured-in-place surfaces (other than loose-fill materials) generally require a professional and are<br />

not "do-it-yourself" projects.<br />

When surfacing is to be used it is recommended to use Playground Surfacing Materials (other than loose-fill materials) which<br />

comply to the safety standard ASTM 1292 Standard Specification for Impact Attenuation of Surfacing Materials within the Use<br />

Zone of Playground Equipment.<br />

Maintenance of your play system<br />

To ensure safe enjoyment of your Rainbow Play System for years to come, follow these maintenance tips:<br />

1. At the beginning of each usage season and twice each month, check and tighten as needed (but do not over<br />

tighten causing the wood to crack) all nuts and bolts. Acorn nuts should be tightened to 5 foot pounds of torque.<br />

Hardware used on swinging elements should be checked at least twice a month to ensure proper fastening.<br />

2. At the beginning of each usage season and twice each month, check all coverings for bolts and sharp edges<br />

to be certain they are in place. Replace when necessary.<br />

3. Oil all metallic moving parts and grease Tire Swivel monthly during the usage period.<br />

4. Check all moving parts including swing seats, ropes, and chains for wear, rust, or other deterioration and replace<br />

as needed.<br />

5. Check all metal parts for rust. If needed, sand and repaint using a nonlead-based paint meeting the<br />

requirements of Title 16 CFR Part 1303.<br />

6. Check the S-Hooks on the chains to ensure the gap is less than .040 inches. Tighten/close as necessary.<br />

7. Remove plastic swing seats and take indoors or do not use when temperature drops below 32 Fahrenheit.<br />

Reinstall swing seats when the cold season is complete.<br />

8. Check, twice a month, the depth of loose fill protective surfacing materials to prevent compaction and to<br />

maintain appropriate depth. Rake or replace as necessary.<br />

9. When you are ready to dispose of your playset, make sure all metal, plastic and wood components are<br />

disposed of in accordance with local waste ordinances and ensure that no unreasonable hazards exist.<br />

10. On a yearly basis, we recommend that you coat your play system with a sealant or preservative. You may<br />

also want to spot sand areas before sealing. Be sure that the sealant you select is non-toxic and child safe.<br />

11. Check all wood members for deterioration and splinters. Spot sand any areas that are checking or<br />

splintering. If parts are deteriorating, replace as needed.<br />

4

Helpful Installation Hints<br />

1. Wear safety glasses to protect your eyes from flying wood chips when drilling or cutting.<br />

2. Verify that all bolts and screws are secured tightly and all acorn nuts are snug (acorn nuts should be<br />

tightened to 5 foot pounds of torque).<br />

3. DO NOT allow children to play on the play system until it is completely assembled in a proper location.<br />

4. DO NOT allow children in the area while you are assembling your play system. Many of the Rainbow Play<br />

Systems, Inc. components are very heavy and could seriously injure a child.<br />

5. After thoroughly reading all information and properly locating your play system site, carefully unpack<br />

parts. As you unpack your play system, keep the parts list handy and become familiar with each part before<br />

beginning assembly. Remember that a little extra time spent familiarizing yourself with the parts and<br />

instructions before you begin will help avoid mistakes and save you time later.<br />

6. Group both wood and non-wood parts together in accordance to each page, or Step, of this assembly<br />

manual. Doing this now will help you quickly locate parts and assemble the set with ease.<br />

7. Sort your hardware into groups of similar hardware pieces. Use a solid surface, such as the empty boxes, to<br />

ensure you do not lose any hardware.<br />

8. Before starting each Step, thoroughly read all of the instructions to ensure all information is understood. Pay<br />

special attention to the orientation of each part, details & notes, and proper usage of hardware. Each piece of<br />

hardware is required for a certain part of the assembly.<br />

9. Certain steps of the assembly are best performed on a hard flat surface to ensure proper and accurate<br />

assembly.<br />

10. All Lag Bolts must have pre-drilled holes 2" deep (as shown in Detail A). Use a 1/8" drill bit for all 1/4" and<br />

5/16" Lag Bolts and use a 1/4" drill bit for all 3/8" Lag Bolts. Lag Bolts can be difficult to put in knot holes.<br />

Pre-drilling pilot holes will help to prevent the Lag Bolts from breaking.<br />

11. All #14 Phillips Pan Head Tap Screws must have pre-drilled holes 1/2" deep. Use a 1/8" drill bit.<br />

12. Use a clamp to secure facias flush to the Uprights and use holes in facia as a guide for placing Lag Bolt Pilot<br />

Holes (as shown in Detail B).<br />

13. Verify Facias are flush with Uprights.<br />

14. Check assembly periodically to ensure the set is level and all facias are square to the uprights.<br />

15. If a gap occurs between boards when inserting Screws or Lag Bolts, back out hardware and apply pressure to<br />

the top board while reinserting hardware in the same hole.<br />

UPRIGHT<br />

PILOT<br />

HOLES<br />

WARNING<br />

Drilling, sawing, sanding or machining wood products generates wood dust,<br />

a substance known to the State of California to cause cancer. Avoid inhaling<br />

wood dust or use a dust mask or other safeguards for personal protection.<br />

California Health and Safety Code Section 25249.6<br />

DETAIL A<br />

FACIA<br />

FACES MUST<br />

BE FLUSH<br />

5<br />

DETAIL B<br />

USE FACIA AS<br />

A GUIDE FOR<br />

PRE-DRILLING<br />

HOLES

COMMONLY ASKED QUESTIONS<br />

Question: How do I know when Lag Bolts and other Fasteners are tightened properly?<br />

Answer: Lag Bolts and other Fasteners are tight when the head of the Lag Bolt and Washer<br />

are firmly compressed against the wood. If splintering occurs, that is an indication you<br />

are over tightening the Lag Bolts and other Fasteners. (Splintering is when the wood<br />

fibers fracture out from under the washers).<br />

Question: What should I do if a Lag Bolt or other Fastener lines up with a knot, or if the Lag Bolt<br />

breaks?<br />

Answer: There is extra Hardware provided with the set for this reason. Re-Drill a new hole with<br />

a 1/8" Drill Bit in a new direction to miss the obstruction.<br />

Question: What if my Play System is leaning and/or rocks?<br />

Answer: This is caused by unleveled ground under the Base and Support Wings of the Play<br />

System. It may be necessary to remove or add some soil beneath the Play System<br />

to make it level. Ground Stakes, when installed, will also provide stability.<br />

Question: What if my Play System has cracks on the wood or seems to be developing cracks?<br />

Answer: Seasonal checks, surface cracks, and knot holes are natural characteristics of all<br />

wooden play equipment. A check is a separation of the wood fibers running with the<br />

grain. This is caused by varying temperature and moisture conditions. By coating<br />

your Play System annually with a sealant or preservative, you can help protect your<br />

Play System from developing (not stopping) seasonal checks. Please remember to<br />

follow all installation instructions, including installing the play set on solid level ground.<br />

Question: What is the sticky substance that appears on the wood?<br />

Answer: The sticky substance that may appear on the wood is called pitch. It is common for<br />

the lumber to have occasional pitch seepage which does not affect the structural<br />

integrity of the part. Pitch provides the natural rot resistant characteristics of the<br />

lumber. If play surfaces or play items become overly sticky with pitch use rubbing<br />

alcohol to safely remove.<br />

Question: What accessories may be added or what modifications can be made to my Rainbow<br />

boxed kit set?<br />

Answer: Rainbow boxed kit sets are complete kits and are not modular. Play sets with<br />

unauthorized accessories or modifications will not be covered under warranty.<br />

Non-residential use of the play set voids warranty.<br />

Question: Is my child old enough to use all play items on my set?<br />

Answer: All play items on Rainbow boxed kit sets are designed<br />

for children ages 3 to 12, but it is the end users<br />

responsibility to determine suitability of use by their<br />

children for each play item.<br />

6<br />

EXAMPLE OF SEASONAL<br />

CHECKS OR SURFACE<br />

CRACKS

200<br />

207<br />

330<br />

331<br />

332<br />

333<br />

641<br />

663<br />

660<br />

406<br />

642<br />

352<br />

53<br />

54<br />

55<br />

56<br />

BACKYARD CIRCUS CLUBHOUSE PARTS LIST<br />

15@ 1 x 4 x 27 1/2" Rail Upright (3-01-0037)<br />

1@ 1 x 4 x 21" Ladder Entrapment Board (3-01-0044)<br />

1@ 1 x 4 x 32 1/2" Top Rock Wall Board (3-01-0093)<br />

6@ 1 x 4 x 32 1/2" 2 Hole Inside Rock Wall Board (3-01-0094)<br />

6@ 1 x 4 x 32 1/2" Rock Wall Board (3-01-0095)<br />

6@ 1 x 4 x 32 1/2" 2 Hole Rock Wall Board (3-01-0096)<br />

2@ 1 x 4 x 45 1/4" Short Deck Board (3-01-0156)<br />

12@ 1 x 4 x 52" Deck Board (3-01-0159)<br />

6@ 1 x 4 x 41" Table Board (3-01-0158)<br />

1@ 1 x 4 x 32 1/2" Rock Wall Board w/Rope Hole (3-01-0123)<br />

1@ 1 x 6 x 52" Deck Board (3-02-0032)<br />

1@ 2 x 4 x 61" Rock Wall Runner (3-03-0005)<br />

1@ 2 x 4 x 19" Table Runner (3-03-0008)<br />

2@ 2 x 4 x 30" Left Picnic Table Leg (3-03-0009)<br />

2@ 2 x 4 x 30" Right Picnic Table Leg (3-03-0010)<br />

2@ 2 x 4 x 18 3/4" Table Brace (3-03-0011)<br />

7

57<br />

58<br />

353<br />

427<br />

646<br />

418<br />

640<br />

226<br />

664<br />

408<br />

661<br />

644<br />

234<br />

BACKYARD CIRCUS CLUBHOUSE PARTS LIST<br />

2@ 2 x 4 x 45" Seat Support (3-03-0012)<br />

2@ 2 x 4 x 19" Table Support (3-03-0013)<br />

2@ 2 x 4 x 62 3/8" Rock Wall Leg (3-03-0021)<br />

1@ 2 x 4 x 5 1/4" Ship's Wheel<br />

Block (3-03-0059)<br />

1@ 2 x 4 x 51" Deck Runner (3-03-0066)<br />

4@ 2 x 6 x 52" 4 Hole Facia (3-04-0011)<br />

2@ 2 x 6 x 52" Main Beam (3-04-0015)<br />

4@ 5/4 x 4 x 27 1/2" Rail Upright w/Handle Holes<br />

(3-09-0003)<br />

6@ 5/4 x 4 x 13 1/8" Corner Facia<br />

(3-09-0086)<br />

2@ 5/4 x 4 x 9" Slide Block (3-09-0036)<br />

2@ 5/4 x 4 x 41" Seat Board<br />

(3-09-0073)<br />

4@ 5/4 x 4 x 52" 2 Hole Facia (3-09-0084)<br />

4@ 5/4 x 6 x 18" Ladder Step (3-10-0004)<br />

8

715<br />

662<br />

647<br />

650<br />

645<br />

639<br />

638<br />

643<br />

648<br />

222<br />

223<br />

77<br />

78<br />

2@ 5/4 x 6 x 52" 6 Hole Facia (3-10-0051)<br />

2@ 5/4 x 6 x 41" Seat Board (3-10-0030)<br />

2@ 5/4 x 6 x 52" 6 Hole Facia (3-10-0041)<br />

3@ 5/4 x 6 x 52" 4 Hole Facia (3-10-0042)<br />

1@ 5/4 x 6 x 52" Facia w/Rope Hole (3-10-0040)<br />

2@ 4 x 4 x 105" Corner Upright w/TJ Holes (1-06-0761)<br />

2@ 4 x 4 x 105" Corner Upright (1-06-0760)<br />

1@ 4 x 4 x 52" Top Joist w/Swing Holes (3-06-0039)<br />

1@ 4 x 6 x 64 9/16" Left Ladder Leg (3-07-0004)<br />

1@ 4 x 6 x 64 9/16" Right Ladder Leg (3-07-0005)<br />

2@ 4 x 4 x 104" A-Frame Leg (3-06-0003)<br />

1@ 4 x 4 x 60" A-Frame Cross Member (3-06-0004)<br />

81 82<br />

1@ 4 x 4 x 15" Upper A-Frame<br />

Bracket (3-06-0007)<br />

346<br />

BACKYARD CIRCUS CLUBHOUSE PARTS LIST<br />

2 @ 4 x 4 x 52" Center Post (3-06-0040)<br />

714 8 @ 4 x 4 x 16" Angled Brace (3-06-0062)<br />

1@ 4 x 6 x 106" 3 Position Swing Beam (3-07-0006)<br />

9<br />

1@ 4 x 4 x 15" Lower A-Frame<br />

Bracket (3-06-0008)

247<br />

2@ 1 x 4 x 17" Fan Vertical (3-01-0052)<br />

200<br />

11 @ 1 x 4 x 27 1/2" Rail Upright<br />

(3-01-0037)<br />

329<br />

363<br />

4@ 1 x 4 x 6 1/2" Chimney Trim (3-01-0092)<br />

1@ 1 x 4 x 13" Fan Vertical (3-01-0099)<br />

362<br />

2@ 1 x 4 x 8 3/4" Fan Ray (3-01-0098)<br />

364<br />

377<br />

1@ 1 x 4 x 15 5/8" Left Dormer Board<br />

1@ 1 x 4 x 3 3/8" Right Dormer<br />

(3-01-0100)<br />

Board (3-01-0113)<br />

365<br />

376<br />

1@ 1 x 4 x 13 9/16" Left Dormer Board<br />

1@ 1 x 4 x 5 7/16" Right Dormer<br />

(3-01-0101)<br />

Board (3-01-0112)<br />

366<br />

375<br />

1@ 1 x 4 x 11 9/16" Left Dormer Board<br />

(3-01-0102)<br />

1@ 1 x 4 x 7 1/2" Right Dormer<br />

Board (3-01-0111)<br />

367<br />

374<br />

1@ 1 x 4 x 9 1/2" Left Dormer Board<br />

(3-01-0103)<br />

1@ 1 x 4 x 9 1/2" Right Dormer<br />

Board (3-01-0110)<br />

368<br />

373<br />

1@ 1 x 4 x 7 1/2" Left Dormer Board<br />

1@ 1 x 4 x 11 9/16" Right Dormer<br />

(3-01-0104)<br />

Board (3-01-0109)<br />

369<br />

372<br />

1@ 1 x 4 x 5 7/16" Left Dormer Board<br />

1@ 1 x 4 x 13 9/16" Right Dormer<br />

(3-01-0105)<br />

Board (3-01-0108)<br />

370 371<br />

1@ 1 x 4 x 3 3/8" Left Dormer Board<br />

1@ 1 x 4 x 15 5/8" Right Dormer<br />

(3-01-0106)<br />

Board (3-01-0107)<br />

399<br />

401<br />

4@ 1 x 4 x 11 3/4" Fan Ray (3-01-0116)<br />

12@ 1 x 4 x 14 1/2" Window Upright<br />

(3-01-0118)<br />

402<br />

11@ 1 x 4 x 14 1/2" Cabin Upright (3-01-0119)<br />

404<br />

6@ 1 x 4 x 15 1/2" Window Board<br />

(3-01-0121)<br />

653<br />

WOOD ROOF ADD-ON PARTS LIST<br />

24@ 1 x 4 x 54 5/8" Roof Board (3-01-0157)<br />

378<br />

379<br />

1@ 1 x 6 x 18" Chimney Front (3-02-0025)<br />

1@ 1 x 6 x 12 1/8" Chimney Back<br />

(3-02-0026)<br />

416<br />

655<br />

2@ 1 x 6 x 44" Fan Horizontal (3-02-0027)<br />

2@ 1 x 6 x 44 3/4" Filler Board<br />

(3-02-0033)<br />

355<br />

1@ 2 x 4 x 26" Fan Horizontal (3-03-0050)<br />

356<br />

1@ 2 x 4 x 6" Fan Center (3-03-0051)<br />

10<br />

659<br />

1 @ 1 x 6 x 27 1/2" Rail Upright<br />

(3-02-0034)

357<br />

1@ 2 x 4 x 24 1/4" Left Dormer Support (3-03-0052)<br />

358<br />

1@ 2 x 4 x 24 1/4" Right Dormer Support (3-03-0053)<br />

359<br />

651<br />

652<br />

380<br />

409<br />

410<br />

654<br />

308<br />

382<br />

390<br />

1@ 2 x 4 x 6 5/8" Chimney Block (3-03-0054)<br />

2@ 2 x 4 x 40" Left Roof Support (3-03-0067)<br />

2@ 2 x 4 x 40" Right Roof Support (3-03-0068)<br />

2@ 5/4 x 4 x 23 1/2" Dormer Runner (3-09-0033)<br />

4@ 5/4 x 4 x 35" Roof Frame Side (3-09-0037)<br />

2@ 5/4 x 4 x 39" Roof Runner (3-09-0038)<br />

4@ 5/4 x 4 x 58 5/8" Roof Frame (3-09-0085)<br />

2@ 5/4 x 6 x 9 1/2" Peak Facia (3-10-0012)<br />

2@ 5/4 x 6 x 17 3/8" Chimney Side (3-10-0016)<br />

2@ 5/4 x 6 x 52" Angled Double Arched Facia (3-10-0018)<br />

656<br />

1@ 5/4 x 6 x 52" Double Arched Facia (3-10-0043)<br />

657<br />

WOOD ROOF ADD-ON PARTS LIST<br />

1@ 5/4 x 6 x 52" Arched Facia (3-10-0044)<br />

11<br />

412<br />

349<br />

6@ 5/4 x 4 x 15 1/2" Window Horizontal<br />

(3-09-0040)<br />

2@ 5/4 x 6 x 9" Fan Center (3-10-0013)

N20<br />

N8<br />

1@ Ship's Wheel<br />

(5-41-0021)<br />

8@ Small 90 Bracket<br />

(5-35-0089)<br />

N29<br />

14@ Bolt Cup<br />

(5-47-0043)<br />

N73<br />

N5<br />

2@ Small Bolt Cup<br />

(5-47-0035)<br />

4@ Safety Handle - Yellow<br />

(5-33-0102)<br />

4@ 90 Bracket<br />

(5-35-0090)<br />

N19<br />

N170 N171 N33<br />

1@ 45 Bracket<br />

(5-35-0094)<br />

N9<br />

2@ 90 Bracket<br />

(5-35-0095)<br />

1@ Telescope<br />

(5-41-0020)<br />

2@ T - Bracket<br />

(5-35-0087)<br />

N83<br />

1@ Plaque<br />

(5-42-0028)<br />

N38<br />

12@ Rock<br />

(5-42-0012/5-42-0021)<br />

N26 N27 N30 N31<br />

6@ Swing Hanger<br />

(5-45-0012)<br />

PARTS IDENTIFICATION<br />

6@ Spring Clip<br />

(5-47-0023)<br />

12<br />

4@ C-Link<br />

(5-47-0044)<br />

N28<br />

6@ Rebar Stake<br />

(5-47-0033)<br />

N10<br />

1@ Swing Beam<br />

Plate - Brown<br />

(5-35-0092)<br />

4@ Pear Link<br />

(5-47-0045)

N18 N14<br />

1@ Trapeze Bar - Yellow<br />

(5-40-0063)<br />

N15<br />

N6<br />

N13<br />

N12<br />

2@ Swing Seats<br />

(5-40-0034/5-40-0049)<br />

2@ Ladder Handle<br />

(5-33-0133)<br />

4@ Long Chain - Yellow<br />

(5-37-0027)<br />

2@ Short Chain - Yellow<br />

(5-37-0026)<br />

PARTS IDENTIFICATION<br />

2@ Trapeze Ring<br />

(5-40-0014)<br />

Parts Not Shown<br />

N24<br />

N264<br />

N1<br />

N17<br />

N169<br />

1@ Double Wall Wave Slide - Yellow (5-44-0139)<br />

1@ Tarp - Green/RYB (5-22-0258/0259)<br />

1@ 12' Rope (5-20-0124)<br />

1@ Half Bucket Swing (designed for children ages 3-5)<br />

1@ 4-Chain Tire Swing (optional)<br />

13

N24<br />

55<br />

54<br />

57<br />

56 662<br />

661<br />

660<br />

58<br />

418<br />

638<br />

639<br />

650<br />

715<br />

664<br />

406<br />

332<br />

333<br />

331<br />

353<br />

650<br />

N5<br />

226<br />

645<br />

664<br />

641<br />

663<br />

642<br />

330<br />

N21<br />

647<br />

644<br />

N264<br />

714<br />

200<br />

77<br />

78<br />

81<br />

82<br />

N171<br />

N170<br />

346<br />

N83<br />

N26<br />

N15<br />

N31<br />

N14<br />

N18<br />

N13<br />

N12<br />

PARTS IDENTIFICATION<br />

14

PARTS IDENTIFICATION<br />

329<br />

N171<br />

346<br />

363<br />

378<br />

654<br />

382<br />

81<br />

653<br />

356<br />

409<br />

362<br />

247<br />

308<br />

82<br />

416<br />

357<br />

399<br />

355<br />

652<br />

77<br />

654<br />

655<br />

412<br />

390<br />

349<br />

401<br />

404<br />

78<br />

647<br />

N5<br />

15<br />

200<br />

N6<br />

223<br />

N24

H7<br />

H1<br />

H30<br />

H32<br />

H34<br />

H28<br />

H17<br />

H24<br />

HARDWARE FOR ASSEMBLY<br />

H93<br />

H108<br />

H116<br />

H155<br />

H154<br />

H152<br />

H194<br />

H176<br />

H157<br />

H158<br />

H166<br />

H164<br />

H163<br />

H169<br />

H170<br />

16<br />

H11<br />

H9<br />

H3<br />

H4<br />

0<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9

H135 H56<br />

H50<br />

HARDWARE FOR ASSEMBLY<br />

*NOTE: Thread length may vary from what is pictured.<br />

H60<br />

17<br />

H124<br />

H184<br />

H55<br />

0<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9

H100<br />

HARDWARE FOR ASSEMBLY<br />

*NOTE: Thread length may vary from what is pictured.<br />

H104<br />

H146<br />

18<br />

H184<br />

H131<br />

H139<br />

0<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9

<strong>Backyard</strong> <strong>Circus</strong> <strong>Club</strong>house Hardware List<br />

F/N# DESCRIPTION DIMENSION QTY<br />

H1 Flat Washer 1/4" 118<br />

H3 Flat Washer 3/8" 29<br />

H4 Flat Washer 1/2" 11<br />

H7 SAE Washer 1/4" 92<br />

H9 Lock Washer 1/4" 12<br />

H11 Lock Washer 3/8" 30<br />

H17 Standard Nut 3/8" 10<br />

H24 Nylock Nut 3/8" 12<br />

H28 Acorn Nut 3/8" 22<br />

H30 Round Pallet Nut 3/8" 4<br />

H32 4 Prong T-Nut 1/4" 44<br />

H34 4 Prong T-Nut 3/8" 4<br />

H50 Carriage Bolt 3/8" x 3 1/2" 2<br />

H55 Carriage Bolt 3/8" x 6" 2<br />

H56 Carriage Bolt 3/8" x 6 1/2" 4<br />

H60 Carriage Bolt 3/8" x 8 1/2" 1<br />

H93 Lag Bolt 1/4" x 2" 6<br />

H100 Lag Bolt 1/4" x 4 1/2" 4<br />

H108 Lag Bolt 5/16" x 3" 104<br />

H116 Lag Bolt 3/8" x 3 1/2" 2<br />

H212 Hex Bolt 1/4" x 3/4" 4<br />

H146 Hex Bolt 1/4" x 2 1/4" 8<br />

H124 Hex Bolt 3/8" x 1 1/2" 2<br />

H184 Hex Bolt 3/8" x 2 1/2" 2<br />

H131 Hex Bolt 3/8" x 4 1/2" 4<br />

H135 Hex Bolt 3/8" x 6 1/2" 12<br />

H139 Hex Bolt 3/8" x 9" 1<br />

H176 Phillips Wood Screw #8 x 1" 174<br />

H194 Phillips Wood Screw #8 x 1 1/4" 258<br />

H152 Phillips Wood Screw #8 x 1 1/2" 334<br />

H154 Phillips Wood Screw #8 x 2" 32<br />

H155 Phillips Wood Screw #8 x 2 1/2" 18<br />

H158 Phillips Pan Head Tap Screw #10 x 1 1/2" 8<br />

H163 Phillips Pan Head Tap Screw #14 x 3/4" 8<br />

H164 Phillips Pan Head Tap Screw #14 x 1" 37<br />

H166 Phillips Pan Head Tap Screw #14 x 1 1/2" 8<br />

H169 Phillips Pan Head Machine Screw 1/4" x 1" 8<br />

H170 Phillips Pan Head Machine Screw 1/4" x 1 1/4" 24<br />

NOTE: EXTRA HARDWARE IS INCLUDED IN THE BAGS.<br />

NOT ALL HARDWARE WILL BE USED TO COMPLETE THE INSTALLATION.<br />

TOOLS REQUIRED FOR ASSEMBLY<br />

Tape Measure<br />

Carpenters Level<br />

Carpenters Square<br />

Rubber Mallet<br />

Claw Hammer<br />

Wood Clamp<br />

Standard or Cordless Drill<br />

with #2 & #3 Phillips Bits<br />

Electric Impact Gun or 1/4"<br />

and 3/8" Ratchet<br />

1/8" Drill Bit<br />

1/4" Drill Bit<br />

5/16" Drill Bit<br />

7/16" Drill Bit<br />

Torque Wrench<br />

Crescent Wrench<br />

19<br />

7/16" Deep Well Socket<br />

1/2" Deep Well Socket<br />

9/16" Deep Well Socket<br />

9/16" Box Wrench<br />

8' Step Ladder<br />

Safety Glasses<br />

Adult Helper

418<br />

418<br />

Step 1<br />

INSET A<br />

638<br />

DETAIL B<br />

H108<br />

1 1/4"<br />

638<br />

H1<br />

H108 H1<br />

Wall Assembly<br />

*NOTE: Pre-drill holes for all 5/16" Lag Bolts with a 1/8" drill bit.<br />

*NOTE: Do not fully tighten through bolt hardware.<br />

1. Position Corner Uprights (638) (639) on the ground. Diagram shows assembly standing up for<br />

proper assembly only. Assemble both wall assemblies separate.<br />

2. Attach Top Joist w/Swing Holes (643) to Corner Uprights (639) using 1/2" Hardware (H4) and 3/8"<br />

Hardware (H3) (H11) (H17) (H28) (H56).<br />

3. Attach bottom 4 Hole Facias (418) to Corner Uprights (638) (639) using 5/16" Hardware (H108)<br />

and 1/4" Hardware (H1). Assembly will measure 52" when properly assembled.<br />

*NOTE: 4 Hole Facias (418) must be flush with bottoms of Corner Uprights (638) (639).<br />

Holes are offset, orient as shown in Inset A.<br />

*SUGGESTION: When installing Facias, put bottom lag bolts in first and check that<br />

measurements are correct and assembly is square before inserting top lag bolts.<br />

4. Measure up 57 3/8" up on Corner Uprights (638) (639).<br />

5. Position Main Beams (640), with inside holes down, and attach using 1/4" Hardware (H1) and<br />

5/16" Hardware (H108).<br />

6. Measure up 87" on Corner Uprights (638) and attach Facia w/Rope Hole (645) using 1/4"<br />

Hardware (H1) and 5/16" Hardware (H108). Tighten all hardware at this time.<br />

638<br />

645<br />

H108<br />

640<br />

418<br />

52"<br />

639<br />

H1<br />

20<br />

B<br />

H56<br />

87"<br />

643<br />

H4<br />

418<br />

H3<br />

H17<br />

H11<br />

57 3/8"<br />

H28

Step 2<br />

1 1/4"<br />

H1<br />

H108<br />

650<br />

HOLE<br />

DOWN<br />

INSET A<br />

638<br />

639<br />

58"<br />

HOLE UP<br />

DETAIL A<br />

H108 647<br />

H1<br />

H108<br />

H108<br />

H1<br />

H1<br />

HOLE DOWN<br />

Wall Assembly<br />

*NOTE: Pre-drill holes for all 5/16" Lag Bolts with a 1/8" drill bit.<br />

*SUGGESTION: Two or three people may be required to complete this step.<br />

1. Stand both wall assemblies up and attach with 4 Hole Facias (418) using 1/4" Hardware (H1) and<br />

5/16" Hardware (H108). Ensure assembly is square. Assembly should measure<br />

52" wide when properly assembled.<br />

*NOTE: 4 Hole Facias (418) must be flush with bottoms of Corner Uprights (638) (639).<br />

Holes are offset, orient as shown in Inset A.<br />

*SUGGESTION: When installing Facias, put bottom lag bolts in first and check that<br />

measurements are correct and assembly is square before inserting top lag bolts.<br />

2. Measure up 58" on Uprights and attach 6 Hole Facia (715), with inside holes down, and 4 Hole<br />

Facias (650) using 1/4" Hardware (H1) and 5/16" Hardware (H108).<br />

*NOTE: Facias (645) (647) (650) (715) must be positioned so holes are offset.<br />

3. Attach 6 Hole Facias (647) to Uprights using 1/4" Hardware (H1) and 5/16" Hardware (H108).<br />

Top faces should be flush with tops of Top Joist (643) and Facia w/Rope Hole (645).<br />

715<br />

418<br />

21<br />

645<br />

418<br />

A<br />

715<br />

418<br />

638<br />

639<br />

643<br />

52"<br />

647<br />

H1<br />

H108

Step 3<br />

N8<br />

H164<br />

646<br />

INSET A<br />

H163<br />

H7<br />

638<br />

715<br />

663<br />

418<br />

Deck Installation<br />

1. Evenly space Deck Boards (641) (642) (663) across Main Beams (640) (as shown).<br />

2. Attach Deck Boards (641) (642) (663) to Main Beams (640) using #8 Hardware (H152).<br />

3. Center Deck Runner (646) on center pre-drilled holes and attach to Deck Boards using #8<br />

Hardware (H152).<br />

4. Center Small 90 Brackets (N8) at the ends of Deck Runner (646) and attach to Runner<br />

(646) and 6 Hole Facias (715) using 1/4" Hardware (H7) and #14 Hardware (H163) (H164).<br />

5. Measure up 25" on Corner Uprights (639) and attach 4 Hole Facia (650) using 1/4" Hardware (H1)<br />

and 5/16" Hardware (H108).<br />

641<br />

418<br />

642<br />

639<br />

22<br />

638<br />

646<br />

650<br />

715<br />

418<br />

639<br />

H152<br />

641<br />

H1<br />

640<br />

25"<br />

H108

714<br />

Step 4<br />

640<br />

*NOTE: Pre-drill holes for all 5/16" Lag Bolts with a 1/8" drill bit. Angled Braces (714) may<br />

split if not pre-drilled as instructed.<br />

1. Position Angled Braces (714) against 6 Hole Facias (715), Main Beams (640), Corner<br />

Uprights (638) (639) and flush against the bottom side of Deck Boards (not shown).<br />

2. Secure Angled Braces (714) in place using 1/4" Hardware (H1) and 5/16" Hardware (H108).<br />

715<br />

DETAIL A<br />

H1<br />

H1<br />

H108<br />

DECK BOARDS HAVE<br />

BEEN REMOVED FROM<br />

THIS VIEW FOR CLARITY<br />

OF ANGLED BRACE<br />

INSTALLATION<br />

H108<br />

714<br />

Angled Brace<br />

Installation<br />

418<br />

639<br />

638 638 639<br />

H108 H1<br />

715<br />

H1<br />

418<br />

23<br />

H108<br />

H1<br />

A<br />

H108<br />

640<br />

H108<br />

715<br />

418

Step 5<br />

664<br />

638<br />

DETAIL A<br />

664<br />

H108<br />

H1<br />

H1<br />

H108<br />

Facia Installation<br />

*NOTE: Pre-drill holes for all 5/16" Lag Bolts with a 1/8" drill bit.<br />

1. Position 2 Hole Facia (644) on Top Joist (643) side of Corner Uprights (639) and attach using 1/4"<br />

Hardware (H1) and 5/16" Hardware (H108).<br />

2. Position Corner Facias (664) (in locations shown) on top of 6 Hole Facias (715) and 4 Hole<br />

Facia (650) and attach to Corner Uprights (638) (639) using 1/4" Hardware (H1) and 5/16"<br />

Hardware (H108).<br />

638<br />

639<br />

643<br />

639<br />

664<br />

A<br />

638<br />

664 644<br />

650<br />

24<br />

715<br />

664<br />

H1<br />

H108

Step 6<br />

H169<br />

H32<br />

Safety Handle<br />

Installation<br />

1. Lay Rail Uprights w/Handle Holes (226) on a flat surface. Install 1/4" Hardware (H32) into<br />

pre-drilled holes (as shown). A small hammer or mallet may be used if needed.<br />

2. Flip Rail Uprights w/Handle Holes (226) and attach Safety Handles (N5) (as shown) using<br />

1/4" Hardware (H169) and previously installed 1/4" Hardware (H32).<br />

226<br />

25<br />

H169<br />

H32<br />

N5<br />

226

Step 7<br />

*NOTE: Install Rail Uprights as shown below if assembling the <strong>Club</strong>house without a Cabin<br />

package.<br />

1. Attach Rail Uprights w/Handle Holes (226) to 6 Hole Facia (647), Facia w/Rope Hole (645), and<br />

Corner Facias (664) using #8 Hardware (H152) (as shown). Flush outside faces (as shown<br />

in Detail A).<br />

2. On sides A, B, and C evenly space Rail Uprights (200) (as shown) and attach to 6 Hole Facias<br />

(647), Corner Facias (664), and Facia w/Rope Hole (645) using #8 Hardware (H194).<br />

3. Attach Rail Uprights (200) to Top Joist (643) and 2 Hole Facia (644) approximately 2 13/16 apart<br />

(as shown) using #8 Hardware (H194).<br />

645<br />

647<br />

200<br />

226<br />

226<br />

A<br />

H152<br />

B<br />

664<br />

200<br />

226<br />

Rail Installation<br />

(for sets without<br />

Cabin Package)<br />

H194<br />

664<br />

26<br />

643<br />

664<br />

FACES<br />

FLUSH<br />

2 13/16"<br />

200<br />

DETAIL A<br />

H194<br />

C<br />

664<br />

226<br />

200<br />

647<br />

644<br />

200

Step 7b<br />

*NOTE: Install Rail Uprights as shown below if installing Cabin package.<br />

1. Attach Rail Uprights w/Handle Holes (226) to 6 Hole Facia (647), Facia w/Rope Hole (645), and<br />

Corner Facias (664) using #8 Hardware (H152) (as shown). Flush outside faces (as shown<br />

in Detail A).<br />

2. On sides A, B, and C evenly space Rail Uprights (200) (as shown) and attach to 6 Hole Facias<br />

(647), Corner Facias (664), and Facia w/Rope Hole (645) using #8 Hardware (H194).<br />

3. Evenly space and attach Rail Uprights (200) (659) to Top Joist (643) and 2 Hole Facia (644)<br />

(as shown) using #8 Hardware (H194).<br />

645<br />

647<br />

200<br />

226<br />

226<br />

A<br />

H152<br />

B<br />

664<br />

200<br />

226<br />

Rail Installation<br />

(for sets with Cabin<br />

Package)<br />

H194<br />

664<br />

26b<br />

643<br />

664<br />

FACES<br />

FLUSH<br />

659<br />

H194<br />

C<br />

DETAIL A<br />

200<br />

664<br />

226<br />

200<br />

647<br />

644<br />

200

Step 8<br />

H32<br />

N21<br />

222<br />

H7<br />

H170<br />

H34<br />

Rock Wall & Step<br />

Ladder T-Nut Installation<br />

*NOTE: Do not fully tighten 3/8" Hardware (H184) (H124) in this step.<br />

1. Position Step Ladder Legs (222) (223) and Rock Wall Legs (353) as shown and install 3/8"<br />

Hardware (H34) into pre-drilled holes. A small hammer or mallet may be used to gently tap<br />

hardware flush with the wood.<br />

2. Install 1/4" Hardware (H32) into pre-drilled holes of Rock Wall Boards (331) (333). Only two Rock<br />

Wall Boards are shown, be sure to complete this step for all Rock Wall Boards (331) (333).<br />

3. Attach 90 Bracket (N9) to Step Ladder Legs (222) (223) using 3/8" Hardware (H11) (H34) (H184).<br />

4. Attach 90 Bracket (N9) to Rock Wall Legs (353) using 3/8" Hardware (H11) (H34) (H124).<br />

5. Attach Rocks (N21) to Rock Wall Boards (331) (333) using 1/4" Hardware (H7) (H170).<br />

*NOTE: Four 1/4" SAE Washers (H7) must be used per Rock installation (as shown).<br />

H11<br />

H184<br />

N9 H34<br />

H32<br />

27<br />

223<br />

N9<br />

H34<br />

N21<br />

H7<br />

H170<br />

333<br />

353<br />

N9<br />

H34<br />

353<br />

N9<br />

H11<br />

H124<br />

331

Step 9<br />

17"<br />

11/16"<br />

223<br />

222<br />

N6<br />

234<br />

H155<br />

N6<br />

Step Ladder<br />

Assembly<br />

*NOTE: To ease assembly, assemble Ladder on a flat surface. Place ends of ladder legs<br />

on boards to allow for centering and attaching Ladder Steps (234) (as shown) in<br />

INSET A.<br />

1. Flush surfaces of Left Step Ladder Leg (222) and Right Step Ladder Leg (223).<br />

2. Center Steps (234) on Ladder Legs (222) (223) (as shown in INSET A) and attach using #8<br />

Hardware (H155).<br />

3. Measure down approximately 1 1/4" from the angled edge of Ladder legs (222) (223) (as shown in<br />

INSET A) and attach Ladder Entrapment Board (207) using #8 Hardware (H152).<br />

4. Measure up 17" from the bottom of Ladder Legs (222) (223) (as shown in INSET A) and attach<br />

Ladder Handles (N6) using #14 Hardware (H166).<br />

INSET A<br />

H166<br />

28<br />

N6<br />

H152<br />

207<br />

N9<br />

207 H152<br />

1 1/4"<br />

N9

Step 10<br />

*NOTE: To ease assembly, assemble Ladder on a flat surface.<br />

1. Position Rock Wall Legs (353) (as shown) on a flat surface. Flush the top end of the Rock Wall<br />

Legs (as shown) in Inset A and Detail A.<br />

2. Position Top Rock Wall Board (330) in place (as shown) and attach using #8 Hardware (H152).<br />

3. Position top two Inside 2 Hole Rock Wall Boards (331) in the locations shown but do not attach at<br />

this time (Boards will not be attached until Step 11).<br />

4. Position Rock Wall Board (332) in location directly below unattached boards and attach using #8<br />

Hardware (H152).<br />

5. Place the rest of the Rock Wall Boards (331) (332) (333) (406) in the proper locations (as shown in<br />

Inset A) but only attach the bottom Rock Wall Board (352) (as shown) using #8 Hardware (H152).<br />

6. Ensure assembly is square and finish attaching all the rock wall boards using #8 Hardware<br />

(H152).<br />

7. Position Rock Wall Runner (352) against the bottom of Top Rock Wall Board (330) and center on<br />

Rock Wall Board holes (as shown in Inset A) and attach to Rock Wall Boards using #8 Hardware<br />

(H152).<br />

H152<br />

332 333 333<br />

DETAIL A<br />

352<br />

30 1/2"<br />

BOTTOM<br />

406<br />

406<br />

FACES<br />

FLUSH<br />

332<br />

353<br />

Rock Wall Assembly<br />

POSITION BOARD<br />

AND ATTACH<br />

POSITION BOARDS<br />

AS SHOWN BUT<br />

DO NOT ATTACH<br />

INSET A<br />

POSITION BOARD<br />

AND ATTACH<br />

333 332 331 332 333 332 331 332 333 332 331 330<br />

29<br />

332<br />

TOP<br />

332<br />

H152<br />

330<br />

1"<br />

13 5/8"<br />

331<br />

32 1/2"

Step 11<br />

715<br />

N9<br />

H7<br />

H164<br />

Rock Wall Assembly<br />

1. Center Ladder Assembly on 6 Hole Facia (715) and attach using 1/4" Hardware (H7) and #14<br />

Hardware (H164).<br />

2. Center Rock Wall Assembly on 4 Hole Facia (650) and attach using 1/4" Hardware (H7) and #14<br />

Hardware (H164).<br />

3. Tighten 3/8" Hardware in 90 Brackets (N9).<br />

4. Install Inside 2 Hole Rock Wall Boards (331) using #8 Hardware (H152).<br />

5. Thread Rope (N1) through Rock Wall Board w/Rope Hole (406) and tie a double knot on the back<br />

side of the rock wall board.<br />

6. Tie three single knots evenly throughout the rope.<br />

7. Thread rope through Facia w/Rope Hole (645) and tie a double knot on the backside of Facia<br />

(645).<br />

645<br />

A<br />

650<br />

H164<br />

30<br />

H7<br />

H164<br />

353<br />

DETAIL A<br />

H7<br />

N9<br />

N38<br />

N1<br />

H152<br />

331<br />

H152<br />

SINGLE KNOTS<br />

406<br />

DOUBLE KNOT<br />

ON BACKSIDE<br />

715<br />

N9

Step 12<br />

715<br />

408<br />

Slide Installation<br />

*NOTE: Use an 1/8" drill bit to drill holes 1/2" deep for #14 Hardware.<br />

1. Center Double Wall Wave Slide (N24) in the opening and position approximately 4" back from the<br />

front face of 6 Hole Facia (715).<br />

2. Position Slide Blocks (408) under the deck boards and attach Slide (N24) through the deck boards,<br />

into Slide Blocks (408) using 1/4" Hardware (H7) and #14 Hardware (H166).<br />

3. Center Small 90 Brackets (N8) behind each Rail Upright w/Handle Holes (226) and the two Rail<br />

Uprights (200) that create the slide opening. Attach to deck and rails using 1/4" Hardware (H7) and<br />

#14 Hardware (H163) (H164) (as shown in INSET A).<br />

200<br />

H166<br />

H7<br />

31<br />

226<br />

200<br />

641<br />

N8<br />

INSET A<br />

H163<br />

N24<br />

H7<br />

H164<br />

H7

Step 13<br />

N13<br />

N31<br />

N15<br />

N17<br />

Swing Assembly<br />

*NOTE: Half-Bucket Swing (N17) is intended for use by children ages 3 to 5, under adult<br />

supervision.<br />

1. Open C-Links (N30) and Pear Links (N31).<br />

*NOTE: When closing C-Links and Pear Links, securely tighten using a crescent wrench.<br />

2. Attach two Long Chains (N13) to each Swing Seat (N15) and Half-Bucket Swing (N17) using Pear<br />

Links (N31) and C-Links (N30) (as shown in Inset A).<br />

3. Attach two Short Chains (N12) to Trapeze Bar (N18) using C-Links (N30) (as shown in Inset A).<br />

4. Attach Trapeze Rings (N14) to Trapeze Bar (N18) by connecting C-Links (N30) to both the Trapeze<br />

Bar (N18) and Trapeze Rings (N14) (as shown in Inset B).<br />

*NOTE: When completed, swing assemblies should look as shown in Inset B.<br />

5. Securely close all C-Links (N30) and Pear Links (N31) by tightening with a crescent wrench.<br />

N13<br />

N30<br />

INSET A<br />

INSET B<br />

32<br />

N12<br />

N30<br />

N30<br />

N14<br />

N18

Step 14<br />

H56<br />

H4<br />

N29<br />

N10<br />

H11<br />

H3<br />

H17<br />

H28<br />

H139<br />

77<br />

H3<br />

N170<br />

H135<br />

N29<br />

N26<br />

H3<br />

H24 H11<br />

H28<br />

H3<br />

H116<br />

A-Frame Assembly &<br />

Swing Hanger Installation<br />

*NOTE: It is possible to modify your 3 Position Swing Beam to a 2 Position Swing Beam for<br />

use in small yards. See Step 31, page 51 for instructions on how to modify the 3<br />

Position Swing Beam to a 2 Position Swing Beam. Proceed with the following steps<br />

after making the modifications.<br />

1. Attach Swing Hangers (N26) to Swing Beam (346) using 3/8" Hardware (H3) (H11) (H24) (H28)<br />

(H135) and 3/8" Bolt Cup (N29).<br />

*SUGGESTION: Use a locking pliers to hold on to Hex Head Bolts (H135).<br />

2. Position Plaque (N83) in the approximate position shown and attach to Swing Beam using #10<br />

Hardware (H157) or (H158) (as shown).<br />

3. Attach Swing Beam Plate (N10) to Swing Beam (346) using 3/8" Bolt Cup (N29), 3/8" Hardware<br />

(H3) (H11) (H17) (H28) (H56), and 1/2" Hardware (H4) (as shown).<br />

*NOTE: Do not fully tighten hardware at this time.<br />

4. Attach Upper A-Frame Block (81) and Lower A-Frame Block (82) (as shown) using 3/8" Hardware<br />

(H3) (H116).<br />

5. Attach A-Frame Legs (77) to A-Frame Block assembly using 45 Bracket (N170) and 3/8" Hardware<br />

(H139) (H3) (H11) (H17).<br />

*NOTE: Do not tighten hardware completely at this time.<br />

6. Lay assembly on the ground with A-Frame Legs (77) pointing in opposite directions.<br />

N83<br />

H158<br />

H157<br />

81<br />

33<br />

82<br />

H3<br />

H11<br />

346<br />

H17<br />

77

Step 15<br />

*NOTE: Pre-drill holes for all Lag Bolts with the appropriate drill bit.<br />

1. On the ground, place Swing Beam (346) on top of Swing Beam Block (81). Align pre-drilled hole and<br />

attach through 45 Bracket (N170) using Bolt Cup (N29), 1/2" Hardware (H4), and 3/8" Hardware<br />

(H56) (H3) (H11) (H17).<br />

2. Make sure Swing Beam (346) is centered on the Swing Beam Block (81). Position 90 Brackets<br />

(N171) on Swing Beam Block (81), up against the Swing Beam (346), and attach using Bolt Cups<br />

(N73), #14 Hardware (H164), 1/4" Hardware (H1) (H100) and 5/16" Hardware (H108) (as shown in<br />

Inset B).<br />

3. Lift Swing Beam assembly into position on top of the Top Joist (643) and attach through Swing Beam<br />

(346) and Swing Beam Plate (N10) using 1/2" Hardware (H4) and 3/8" Hardware (H50) (H60) (H3)<br />

(H11) (H17) (as shown in Inset A).<br />

*NOTE: For ease of installation, insert Carriage Bolt (H60) through the Swing Beam (346), and<br />

then insert Carriage Bolts (H50). Do not tighten hardware at this time.<br />

4. Lift Swing Beam assembly up until A-Frame Legs hold Swing Beam in a level position.<br />

*CAUTION: Legs will close inward as Swing Beam is lifted up into position.<br />

*SUGGESTION: Use at least two people to lift Swing Beam assembly.<br />

*CAUTION: Legs are very unstable until Cross Member (78) is installed.<br />

5. Tighten Hex Head Bolt (H139) that goes through A-Frame Legs (77) and A-Frame Block assembly<br />

and attach 3/8" Hardware (H28). Tighten all hardware that goes through Swing Beam Plate (N10) at<br />

this time.<br />

6. Hold A-Frame Cross Member (78) in a level position against A-Frame Legs (77) so holes are centered<br />

on A-Frame Legs, and drill through A-Frame Legs using a 7/16" drill bit. Attach Cross Member using<br />

3/8" Hardware (H55) (H3) (H11) (H17) and 1/2" Hardware (H4).<br />

7. Attach A-Frame Legs (77) to A-Frame Blocks using 1/4" Hardware (H1) (H100).<br />

8. Place 3/8" Acorn Nuts (H28) on all Hardware that goes through Swing Beam Plate (N10), A-Frame<br />

Cross Member (78) and 45 Bracket (N170) after all Hardware is tightened.<br />

9. Attach Spring Clips (N27) to Swing Hangers (N26).<br />

10. Attach Swing Options to Spring Clips (N27).<br />

Swing Beam<br />

Installation<br />

*NOTE: There must be no less than 8" from the ground to the bottom of Sling Swing, Tire<br />

Swing and Half Bucket Swing when properly installed.<br />

*NOTE: Only ONE Swing Option in each opening on the Swing Beam.<br />

*NOTE: If installing 4 Chain Tire Swing see Step 30, page 50 for assembly instructions.<br />

34<br />

Continued on next page:

Step 15<br />

Continued from previous page:<br />

N10<br />

643<br />

H3<br />

H11<br />

H17<br />

H60<br />

H28<br />

INSET A<br />

643<br />

H4 H50<br />

N26<br />

N27<br />

H4<br />

346<br />

H55 H4<br />

Swing Beam<br />

Installation<br />

N170<br />

H11<br />

346<br />

H3<br />

H28<br />

77<br />

H17<br />

35<br />

H164<br />

H108<br />

H3<br />

H11<br />

H56<br />

H4<br />

N29<br />

H1<br />

H28 H17<br />

78<br />

INSET B<br />

81<br />

82<br />

346<br />

H1 H100<br />

H28<br />

77<br />

H100<br />

N73<br />

H164<br />

N171<br />

82<br />

81<br />

H4 H55

Step 16<br />

SHIP'S WHEEL<br />

HARDWARE<br />

N20<br />

N20<br />

H155<br />

Ship's Wheel &<br />

Telescope Installation<br />

*NOTE: Do not over-tighten Hardware. Ship's Wheel (N20) and Telescope Base<br />

(N19) should rotate freely.<br />

*NOTE: Pre-drill holes for all Lag Bolts with 1/8" drill bit.<br />

1. Position Ship's Wheel Block (427) against the end of Swing Beam (346) and attach using #8<br />

Hardware (H155).<br />

2. Center Ship's Wheel (N20) on Ship's Wheel Block (427) and attach using Hardware provided in<br />

Ship's Wheel Bag. Snap cap into place.<br />

3. Center Base of Telescope (N19) on Top Joist (643) and attach using Hardware provided in<br />

Telescope Bag. Snap Telescope (N19) into base.<br />

643<br />

36<br />

TELESCOPE<br />

HARDWARE<br />

427<br />

N19<br />

N19<br />

346

Step 17<br />

648<br />

INSET A<br />

H108<br />

638<br />

H1<br />

647<br />

N33<br />

647<br />

BOTTOMS<br />

FLUSH<br />

644<br />

H164<br />

648<br />

H7<br />

H108<br />

H1<br />

Tarp Installation<br />

*NOTE: If installing Wood Roof option skip to Step 19, page 39.<br />

*NOTE: Pre-drill holes for all 5/16" Lag Bolts with 1/8" drill bit.<br />

1. Line up the larger center hole on T-Brackets (N33) with the top pre-drilled hole on 6 Hole Facia<br />

(647) and attach 6 Hole Facia (647), T-Bracket (N33), and Center Post (648) together using 1/4"<br />

Hardware (H1) and 5/16" Hardware (H108). Center Posts and 6 Hole Facias should be flush on<br />

the bottom (as shown in Inset A).<br />

2. Use a level and square to ensure T-Brackets (N33) and Center Posts (648) are square with 6 Hole<br />

Facias (647) and secure T-Brackets (N33) and Center Posts (648) in place using 1/4" Hardware<br />

(H7) and #14 Hardware (H164).<br />

3. Finish attaching Center Posts (648) to 6 Hole Facias (647) using 1/4" Hardware (H1) and 5/16"<br />

Hardware (H108) through the bottom hole of the 6 Hole Facias (647).<br />

4. Position 2 Hole Facias (644) on Corner Uprights (638) (639) and Center Posts (648) and attach<br />

using 1/4" Hardware (H1) and 5/16" Hardware (H108).<br />

H108<br />

H1<br />

N33<br />

638<br />

639<br />

644<br />

37<br />

H1<br />

H108<br />

N33<br />

H7<br />

648<br />

H164<br />

644<br />

H108<br />

H1<br />

639<br />

647

Step 18<br />

644<br />

INSET A<br />

644<br />

H182<br />

N264<br />

Tarp Installation<br />

1. Evenly spread Tarp (N264) over the top of the 2 Hole Facia (644) (as shown). Female ends of the<br />

tarp snaps should face in towards each other when the tarp is freely hanging.<br />

2. Wrap Tarp (N264) around the bottom side of 2 Hole Facias (644). Starting with the middle tarp<br />

snap, work your way out gently tapping each tarp snap to leave an indentation in the wood.<br />

3. Install Snap Screws (H182) in the center of the indentations.<br />

*NOTE: Snap Screws (H182) are rolled up in the Tarp.<br />

4. Snap the Tarp (N264) to the Snap Screws (H182).<br />

5. Repeat parts 2, 3, and 4 for the other side. Ensure Tarp (N264) is pulled tight when marking Snap<br />

Screw (H182) locations.<br />

38<br />

644<br />

N264<br />

644

Step 19<br />

H131<br />

H11<br />

638<br />

639<br />

H30<br />

H3<br />

651<br />

DETAIL A<br />

308<br />

647<br />

H30<br />

639<br />

651<br />

H154<br />

FLUSH<br />

FACES<br />

652<br />

Wood Roof<br />

Installation<br />

*SUGGESTION: Have a helper hold Roof Supports (651) (652) in place.<br />

1. Install 3/8" Hardware (H30) into pre-drilled holes of Corner Posts (638) (639) (as shown) by gently<br />

tapping with a hammer until flush with face of wood.<br />

2. Position and attach Left and Right Roof Supports (651) (652) (as shown) using 3/8" Hardware (H3)<br />

(H11) (H30) (H131). Do not fully tighten hardware at this time.<br />

3. Flush faces of Roof Supports (651) (652) and Peak Facias (308) (as shown in Detail B) and attach<br />

Peak Facias using #8 Hardware (H154).<br />

*NOTE: Tighten 3/8" Hardware (H131) at this time.<br />

4. Insert 1/4" Hardware (H32) in extra holes in 6 Hole Facias (647) and attach using 1/4" Hardware<br />

(H1) (H9) (H212).<br />

FLUSH<br />

FACES<br />

652<br />

39<br />

H154<br />

638<br />

H32<br />

H9<br />

H1<br />

H30<br />

651<br />

DETAIL B<br />

308<br />

H212<br />

308<br />

651<br />

H3<br />

652<br />

H11<br />

H131<br />

639<br />

647<br />

FLUSH<br />

FACES

Step 20<br />

653<br />

654<br />

651<br />

NO GAP<br />

H152<br />

INSET A<br />

35"<br />

654<br />

653<br />

654<br />

308<br />

652<br />

H152 H176 H152<br />

410<br />

Wood Roof<br />

Installation<br />

*NOTE: Holes in Roof Frame (654) boards are offset. Position boards correctly as shown<br />

below.<br />

1. Center top Roof Frame (654) boards on Roof Supports (651) (652) and attach using #8 Hardware<br />

(H152) (as shown in Insets A & B). Top Roof Frame (654) boards should overhang Peak Facia<br />

(308) approximately 1 1/8". Roof Frames (654) should form a peak without gaps between boards<br />

(as shown in INSET A).<br />

2. Measure down 35" from the bottom of the Roof Frames (654) on BOTH Roof Supports and attach<br />

bottom Roof Frames (654) to Roof Supports using #8 Hardware (H152).<br />

3. Position Roof Boards (653) on Roof Supports (651) (652) between the top and bottom Roof Frame<br />

(654) boards. Center Roof Boards (653) on Roof Supports (651) (652), space evenly, and attach<br />

using #8 Hardware (H152).<br />

4. After attaching the first 5-6 Roof Boards (653) (on each side of roof), center and attach Roof<br />

Runner (410) to Roof Boards (653) using #8 Hardware (H176), and to Roof Frames (654) using #8<br />

Hardware (H152).<br />

5. Finish attaching the rest of Roof Boards (653) to Roof Supports (651) (652) using #8 Hardware<br />

(H152) and to Roof Runner (410) using #8 Hardware (H176).<br />

40<br />

308<br />

H152<br />

INSET B<br />

651<br />

654<br />

654<br />

308<br />

1 1/4"<br />

1 1/8"<br />

652

Step 21<br />

1. Position Roof Frame Sides (409) in locations shown and attach to Roof Boards (653) using #8<br />

Hardware (H152). When properly installed, outside faces of Roof Frames (654) and Roof Frame<br />

Sides (409) should be flush.<br />

2. Repeat for other side of Roof.<br />

409<br />

654<br />

H152<br />

654<br />

Wood Roof<br />

Installation<br />

653<br />

41<br />

654<br />

409<br />

409<br />

410<br />

DETAIL A<br />

A<br />

FACES<br />

FLUSH<br />

409

Step 22<br />

H108<br />

H1<br />

656<br />

Cabin Facia<br />

Installation<br />

1. Position Angled Double Arched Facias (390) up against the bottom of Roof Supports (651) (652)<br />

and attach using 1/4" Hardware (H1) and 5/16" Hardware (H108). Angled Double Arched Facias<br />

(390) and Roof Supports (651) (652) should have minimal gaps between surfaces.<br />

2. Position Arched Facia (657) and Double Arched Facia (656) (in locations shown) with bottoms<br />

flush to the bottoms of Angled Double Arched Facias (390) (as shown in Inset A) and attach to<br />

Uprights using 1/4" Hardware (H1) and 5/16" Hardware (H108).<br />

42<br />

390<br />

390<br />

BOTTOM<br />

FACES<br />

FLUSH<br />

651<br />

657<br />

INSET A<br />

652<br />

H1<br />

656<br />

H108<br />

NO<br />

GAP

Step 23<br />

404<br />

H194<br />

401<br />

412<br />

404<br />

A<br />

INSET A<br />

16 1/4"<br />

402<br />

H194<br />

H194<br />

401<br />

11 1/4"<br />

402<br />

200<br />

Cabin Rail<br />

Installation<br />

*NOTE: All window openings must have Window Uprights (401) on each side with holes<br />

facing in (as shown in Inset A).<br />

*NOTE: Window Uprights (401) and Cabin Uprights (402) should rest on top of or flush with<br />

tops of Rail Uprights (200) (226).<br />

1. Using the measurements provided in the diagrams below, install Window Uprights (401) and Cabin<br />

Uprights (402) in locations shown using #8 Hardware (H194).<br />

2. Center Window Horizontals (412) vertically and horizontally on Window Uprights (401) pre-drilled<br />

holes and attach through the Window Uprights (401) using #8 Hardware (H194) (as shown in<br />

Inset A).<br />

3. Center Window Vertical (404) on pre-drilled hole of Window Horizontal (412) and attach through<br />

Window Horizontal (412) using #8 Hardware (H194).<br />

4. Secure the top and bottom of Window Verticals (404) in place by attaching to Facias using #8<br />

Hardware (H194).<br />

412<br />

390<br />

401<br />

43<br />

401<br />

402<br />

16 1/4"<br />

H194<br />

11 1/4"<br />

402

Step 24<br />

H194<br />

655<br />

INSET A<br />

416<br />

651<br />

399<br />

247<br />

247<br />

638<br />

399<br />

Fan Installation<br />

1. Position Filler Boards (655) in between Uprights (638) (639) and with the top edge approximately<br />

2 1/4" up from tops of Uprights (638) (639) and attach to Roof Supports (651) (652) using #8<br />

Hardware (H152).<br />

2. On a flat surface position Fan Horizontal (416), Fan Vertical (247), and Fan Center (349) (as<br />

shown) and attach using #8 Hardware (H194).<br />

3. Position Fan Rays (399) (as shown in Inset A & B) and attach to Fan Center (349) using #8<br />

Hardware (H194).<br />

4. Position Fan assembly directly on top of Filler Boards (655) and attach to Roof Supports (651)<br />

(652) using #8 Hardware (H152).<br />

652<br />

652<br />

416<br />

44<br />

349<br />

H152<br />

399<br />

3"<br />

247<br />

H152<br />

INSET B<br />

399<br />

247<br />

651<br />

416<br />

655<br />

45°<br />

17 1/2"<br />

2 1/4"<br />

639

Step 25<br />

358<br />

364<br />

365<br />

366<br />

367<br />

368<br />

369<br />

370<br />

371<br />

362<br />

363<br />

357<br />

355<br />

INSET A<br />

H152<br />

H154<br />

355<br />

Dormer Assembly<br />

1. On a flat surface arrange Right Dormer Support (358), Left Dormer Support (357), and Fan<br />

Horizontal (355) (as shown in Inset A & B) and attach using #8 Hardware (H154).<br />

2. Position Fan Vertical (363) and Fan Rays (362) and Fan Center (356) (as shown in Inset A & B)<br />

and attach using #8 Hardware (H152).<br />

3. Attach top two Roof Boards (364) (371) to Dormer Supports (357) (358) using #8 Hardware<br />

(H152). The top two Roof Boards should not have gaps at the peak.<br />

4. Continue attaching all Roof Boards to Dormer Supports (357) (358) using #8 Hardware (H152).<br />

5. Position Dormer Runners (380) (as shown in lower right diagram) and attach to Roof Boards using<br />

#8 Hardware (H176) and to Dormer Supports (357) (358) using #8 Hardware (H154). When<br />

Dormer Runners (380) are properly installed, they should measure approximately 3/4" in from the<br />

farthest point on the Dormer Boards.<br />

H152<br />

H152<br />

357<br />

355<br />

15/16"<br />

358<br />

45<br />

377<br />

376<br />

362<br />

375<br />

357<br />

3/4"<br />

H152<br />

374<br />

373<br />

356<br />

372<br />

INSET B<br />

371<br />

H154<br />

363<br />

358<br />

45°<br />

7 7/8"<br />

H152<br />

3/4"<br />

362<br />

364<br />

H176<br />

380<br />

H154

Step 26<br />

INSET A<br />

H152<br />

Dormer Installation<br />

1. Position Dormer assembly on roof. Dormer assembly should be centered horizontally and Dormer<br />

Supports (357) (358) should be flush with bottom edge of the third Roof Board (653).<br />

2. Attach Dormer assembly to the roof through Roof Boards (653), into Dormer Runners (380) using<br />

#8 Hardware (H152).<br />

357<br />

46<br />

380<br />

INSET B<br />

653<br />

358<br />

653

Step 27<br />

H154<br />

H152<br />

379<br />

H194<br />

INSET A<br />

378<br />

329<br />

653<br />

359<br />

382<br />

11"<br />

Chimney Installation<br />

1. On a flat surface, stand Chimney Sides (382), Chimney Back (379), and Chimney Front (378) on<br />

end (as shown) and attach using #8 Hardware (H152). Angled faces of Chimney parts should be<br />

flush.<br />

2. Center Chimney Trim (329) pieces on Chimney Sides (382) and attach using #8 Hardware (H194).<br />

3. Center Chimney Trim (329) pieces on Chimney Back (379) and Chimney Front (378) and attach<br />

using #8 Hardware (H194).<br />

4. Place Chimney Block (359) flush with angled faces of Chimney Sides (382) and attach through<br />

Chimney Sides (382) using #8 Hardware (H154).<br />

5. Position Chimney assembly on roof in desired location and attach through the underside of Roof<br />

Boards (653) into Chimney Block (359) using #8 Hardware (H152).<br />

H154<br />

H194<br />

47<br />

653<br />

INSET B<br />

H152

Step 28<br />

H146<br />

55<br />

H146<br />

H1<br />

H9<br />

H1<br />

H9<br />

H1<br />

57<br />

58<br />

54<br />

Picnic Table<br />

Assembly<br />

1. Place Left Table Legs (54), Right Table Legs (55) and Seat Supports (57) on a hard surface and<br />

pound in T-Nuts (H32) with a hammer (as shown in Inset A).<br />

*NOTE: Counter-sunk holes on Table Legs (54) (55) must be facing down.<br />

2. Line up holes on Left Table Legs (54), Right Table Legs (55), Seat Supports (57) and Table Support<br />

(58) (as shown) and attach using 1/4" Hardware (H1) (H9) (H146) (H32).<br />

57<br />

54<br />

57<br />

48<br />

H1<br />

H9<br />

55<br />

55<br />

H146<br />

54<br />

58<br />

55<br />

54<br />

H1<br />

H9<br />

H146<br />

H32<br />

H32<br />

INSET A<br />

H32

Step 29<br />

662<br />

661<br />

57<br />

660<br />

58<br />

H154<br />

53<br />

H154<br />

56<br />

H154<br />

H152<br />

55 54<br />

Picnic Table<br />

Assembly<br />

1. Stand Leg assemblies up and center Seat Boards (661) (662) on Seat Supports (57). Seat Boards<br />

(661) (662) should overhang 5 7/8" on the ends and the edges of Seat Boards (662) and Seat<br />

Supports (57) must be flush (as shown). Attach Seat Boards (661) (662) to Seat Supports (57)<br />

using #8 Hardware (H154).<br />

2. Center Table Boards (660) on Table Supports (58) and attach using #8 Hardware (H152). Table<br />

should not have gaps between Table Boards (660) when properly assembled.<br />

*NOTE: Assembling Picnic Table on a hard level surface will help ensuring that the<br />

Table is square.<br />

3. Insert Screws (H154) into holes on Left Table Legs (54) and Right Table Legs (55) and attach to<br />

Table Supports (58) using #8 Hardware (H154).<br />

4. Center and attach Table Runner (53) on the bottom side of Table Boards (660) using #8 Hardware<br />

(H152).<br />