You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

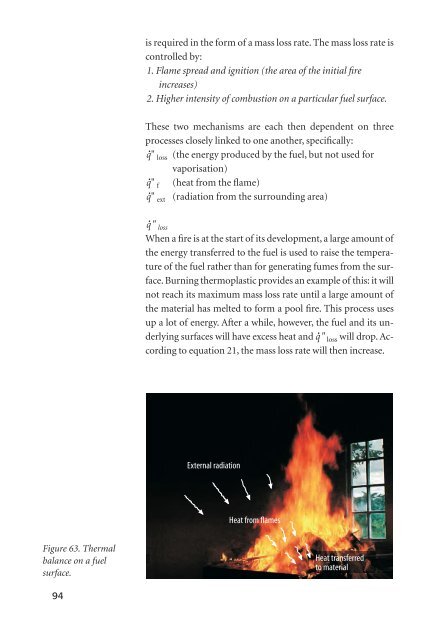

Figure 63. Thermal<br />

balance on a fuel<br />

surface.<br />

94<br />

is required in the form of a mass loss rate. The mass loss rate is<br />

controlled by:<br />

1. Flame spread and ignition (the area of the initial fi re<br />

increases)<br />

2. Higher intensity of combustion on a particular fuel surface.<br />

These two mechanisms are each then dependent on three<br />

processes closely linked to one another, specifi cally:<br />

q" loss (the energy produced by the fuel, but not used for<br />

vaporisation)<br />

q" f (heat from the fl ame)<br />

q" ext (radiation from the surrounding area)<br />

q" loss<br />

When a fi re is at the start of its development, a large amount of<br />

the energy transferred to the fuel is used to raise the temperature<br />

of the fuel rather than for generating fumes from the surface.<br />

Burning thermoplastic provides an example of this: it will<br />

not reach its maximum mass loss rate until a large amount of<br />

the material has melted to form a pool fi re. This process uses<br />

up a lot of energy. After a while, however, the fuel and its underlying<br />

surfaces will have excess heat and q" loss will drop. According<br />

to equation 21, the mass loss rate will then increase.<br />

External radiation<br />

Heat from flames<br />

Heat transferred<br />

to material