- Page 1 and 2: Engineers’ Guide to Pressure Equi

- Page 3 and 4: About the Author Cliff has extensiv

- Page 5 and 6: Foreword During the course of my ca

- Page 7 and 8: vi Engineers’ Guide to Pressure E

- Page 9 and 10: viii Engineers’ Guide to Pressure

- Page 11 and 12: x Engineers’ Guide to Pressure Eq

- Page 13 and 14: 2 Engineers’ Guide to Pressure Eq

- Page 15 and 16: 4 Engineers’ Guide to Pressure Eq

- Page 17 and 18: 6 Engineers’ Guide to Pressure Eq

- Page 19 and 20: Plant 'blocks' Units Plant systems

- Page 21 and 22: CHAPTER 2 Pressure Equipment Types

- Page 23 and 24: Pressure Equipment Types and Compon

- Page 25 and 26: Fig. 2.2 Heat exchanger symbols. (C

- Page 27 and 28: Fig. 2.4 Piping and fittings symbol

- Page 29 and 30: Pressure Equipment Types and Compon

- Page 31 and 32: CHAPTER 3 Basic Design 3.1 Introduc

- Page 33 and 34: Basic Design 23 3.2.2 Safety first

- Page 35 and 36: Basic Design 25 Fig. 3.3 Longitudin

- Page 37 and 38: Basic Design 27 Solving these two e

- Page 39 and 40: Basic Design 29 head are, therefore

- Page 41 and 42: Basic Design 31 Section through cri

- Page 43 and 44: 3.2.8 Pipes and flanges Basic Desig

- Page 45 and 46: Basic Design 35 The spacing of vess

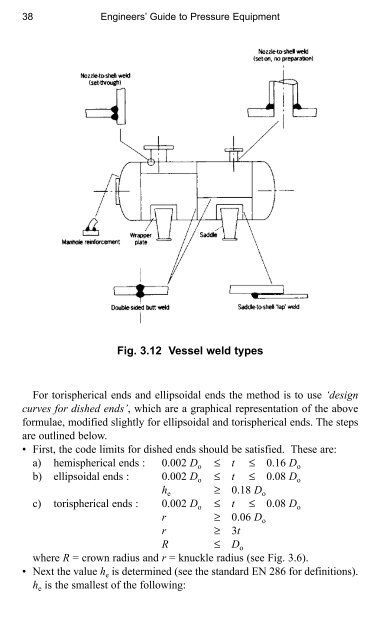

- Page 47: Basic Design 37 These are low carbo

- Page 51 and 52: Table 3.1 Gas cylinder standard EN

- Page 53 and 54: Basic Design 43 • Radiographic te

- Page 55 and 56: Basic Design 45 Fig. 3.16 BS EN 144

- Page 57 and 58: Basic Design 47 3.5 Heat exchangers

- Page 59 and 60: Basic Design 49 Fig. 3.18 Heat exch

- Page 61 and 62: Basic Design 51 Sliding head and O-

- Page 63 and 64: Basic Design 53 where A = surface a

- Page 65 and 66: Feed inlet Feed outlet Toroidal hea

- Page 67 and 68: Basic Design 57 Table 3.4 pr EN 134

- Page 69 and 70: 60 Engineers’ Guide to Pressure E

- Page 71 and 72: 62 Engineers’ Guide to Pressure E

- Page 73 and 74: 64 4.5 PD 5500 Engineers’ Guide t

- Page 75 and 76: 66 Engineers’ Guide to Pressure E

- Page 77 and 78: 68 Engineers’ Guide to Pressure E

- Page 79 and 80: 70 PED Annex 1 clause Engineers’

- Page 81 and 82: 72 Engineers’ Guide to Pressure E

- Page 83 and 84: 74 Engineers’ Guide to Pressure E

- Page 85 and 86: 76 4.6 The ASME vessel codes 4.6.1

- Page 87 and 88: 78 3 Materials • Permissible mate

- Page 89 and 90: 80 Engineers’ Guide to Pressure E

- Page 91 and 92: Product/material Wrought or cast fe

- Page 93 and 94: 84 Thick cylindrical shells under i

- Page 95 and 96: 86 sets of rules governing openings

- Page 97 and 98: 88 Engineers’ Guide to Pressure E

- Page 99 and 100:

90 Engineers’ Guide to Pressure E

- Page 101 and 102:

92 Engineers’ Guide to Pressure E

- Page 103 and 104:

94 Engineers’ Guide to Pressure E

- Page 105 and 106:

96 Table 4.16 Construction to ASME

- Page 107 and 108:

98 • Production test plates • E

- Page 109 and 110:

100 Engineers’ Guide to Pressure

- Page 111 and 112:

102 1 Boiler feed pump 2 Feed check

- Page 113 and 114:

104 Engineers’ Guide to Pressure

- Page 115 and 116:

106 Engineers’ Guide to Pressure

- Page 117 and 118:

108 Engineers’ Guide to Pressure

- Page 119 and 120:

110 Pressure tubes Boiler/ superhea

- Page 121 and 122:

CHAPTER 5 Manufacture, QA, Inspecti

- Page 123 and 124:

Manufacture, QA, Inspection, and Te

- Page 125 and 126:

Manufacture, QA, Inspection, and Te

- Page 127 and 128:

These are relevant mainly to gas cy

- Page 129 and 130:

Fig. 5.3 Vessel misalignment and di

- Page 131 and 132:

So: Manufacture, QA, Inspection, an

- Page 133 and 134:

5.4.4 Vacuum leak testing Vacuum te

- Page 135 and 136:

Manufacture, QA, Inspection, and Te

- Page 137 and 138:

Manufacture, QA, Inspection, and Te

- Page 139 and 140:

Manufacture, QA, Inspection, and Te

- Page 141 and 142:

Manufacture, QA, Inspection, and Te

- Page 143 and 144:

Manufacture, QA, Inspection, and Te

- Page 145 and 146:

Standard code ASTM Material Yield k

- Page 147 and 148:

140 Engineers’ Guide to Pressure

- Page 149 and 150:

142 Engineers’ Guide to Pressure

- Page 151 and 152:

144 Engineers’ Guide to Pressure

- Page 153 and 154:

146 Engineers’ Guide to Pressure

- Page 155 and 156:

148 Engineers’ Guide to Pressure

- Page 157 and 158:

150 Engineers’ Guide to Pressure

- Page 159 and 160:

152 Engineers’ Guide to Pressure

- Page 161 and 162:

154 Engineers’ Guide to Pressure

- Page 163 and 164:

156 Engineers’ Guide to Pressure

- Page 165 and 166:

158 Engineers’ Guide to Pressure

- Page 167 and 168:

160 Engineers’ Guide to Pressure

- Page 169 and 170:

162 90° long radius elbow Engineer

- Page 171 and 172:

164 System Unit Job Engineers’ Gu

- Page 173 and 174:

CHAPTER 7 Boilers and HRSGs Boilers

- Page 175 and 176:

Boilers and HRSGs 169 Figures 7.2 a

- Page 177 and 178:

Kg/cm 2 x 0.09807 x 14.223 Boilers

- Page 179 and 180:

Boilers and HRSGs 173 The critical

- Page 181 and 182:

Boilers and HRSGs 175 Low-pressure

- Page 183 and 184:

Boilers and HRSGs 177 Table 7.2 Typ

- Page 185 and 186:

Boilers and HRSGs 179 operated type

- Page 187 and 188:

Boilers and HRSGs 181 • Shrink is

- Page 189 and 190:

7.2.4 HRSG materials Table 7.3 show

- Page 191 and 192:

186 Engineers’ Guide to Pressure

- Page 193 and 194:

321 ASTM A240, Wk 1.4541, 18/8/Ti,

- Page 195 and 196:

190 Engineers’ Guide to Pressure

- Page 197 and 198:

192 Engineers’ Guide to Pressure

- Page 199 and 200:

CHAPTER 9 Welding and NDT 9.1 Weld

- Page 201 and 202:

Welding and NDT 197 Fig. 9.2 Weld p

- Page 203 and 204:

Welding and NDT 199 Fig. 9.3 BS wel

- Page 205 and 206:

Welding and NDT 201 Fig. 9.5 MMA we

- Page 207 and 208:

Welding and NDT 203 Fig. 9.9 FCA we

- Page 209 and 210:

ange of approval involved. The prin

- Page 211 and 212:

Welding and NDT 207 Fig. 9.13 Tensi

- Page 213 and 214:

9.5 Non-destructive testing (NDT) t

- Page 215 and 216:

Welding and NDT 211 Fig. 9.16 Dye p

- Page 217 and 218:

Defects are classified into: •

- Page 219 and 220:

Welding and NDT 215 pressures equip

- Page 221 and 222:

Welding and NDT 217 Fig. 9.20 Ultra

- Page 223 and 224:

9.5.5 Radiographic testing (RT) Wel

- Page 225 and 226:

Welding and NDT 221 A single-wall X

- Page 227 and 228:

9.6 NDT acronyms Welding and NDT 22

- Page 229 and 230:

Welding and NDT 225 WFMPI Wet Fluor

- Page 231 and 232:

Welding and NDT 227 ASME VIII Radio

- Page 233 and 234:

CHAPTER 10 Failure 10.1 How pressur

- Page 235 and 236:

10.1.2 Multi-axis stress states Fai

- Page 237 and 238:

Failure 233 Stresses in engineering

- Page 239 and 240:

Failure 235 where: Sw(b) = fatigue

- Page 241 and 242:

Failure 237 What is a typical creep

- Page 243 and 244:

Incomplete tin coating Failure 239

- Page 245 and 246:

Deposit of Fe (OH)3 Oxygen OH - Cat

- Page 247 and 248:

Pitting corrosion Stress corrosion

- Page 249 and 250:

Failure 245 Cathode In a corrosion

- Page 251 and 252:

Failure 247 Graphitization A metall

- Page 253 and 254:

CHAPTER 11 Pressure Equipment: Dire

- Page 255 and 256:

Pressure Equipment: Directives and

- Page 257 and 258:

Pressure Equipment: Directives and

- Page 259 and 260:

Pressure Equipment: Directives and

- Page 261 and 262:

Pressure Equipment: Directives and

- Page 263 and 264:

Pressure Equipment: Directives and

- Page 265 and 266:

Pressure Equipment: Directives and

- Page 267 and 268:

Pressure Equipment: Directives and

- Page 269 and 270:

Standardization body Pressure Equip

- Page 271 and 272:

Pressure Equipment: Directives and

- Page 273 and 274:

Pressure Equipment: Directives and

- Page 275 and 276:

• The approach Unlike the PED, th

- Page 277 and 278:

Pressure Equipment: Directives and

- Page 279 and 280:

Pressure Equipment: Directives and

- Page 281 and 282:

Determine fluid group (Page 7) Tabl

- Page 283 and 284:

Pressure Equipment: Directives and

- Page 285 and 286:

Pressure Equipment: Directives and

- Page 287 and 288:

Pressure Equipment: Directives and

- Page 289 and 290:

Pressure Equipment: Directives and

- Page 291 and 292:

Pressure Equipment: Directives and

- Page 293 and 294:

Pressure Equipment: Directives and

- Page 295 and 296:

Pressure Equipment: Directives and

- Page 297 and 298:

Pressure Equipment: Directives and

- Page 299 and 300:

Pressure Equipment: Directives and

- Page 301 and 302:

Pressure Equipment: Directives and

- Page 303 and 304:

Pressure Equipment: Directives and

- Page 305 and 306:

Pressure Equipment: Directives and

- Page 307 and 308:

Pressure Equipment: Directives and

- Page 309 and 310:

Pressure Equipment: Directives and

- Page 311 and 312:

Pressure Equipment: Directives and

- Page 313 and 314:

Pressure Equipment: Directives and

- Page 315 and 316:

Pressure Equipment: Directives and

- Page 317 and 318:

Pressure Equipment: Directives and

- Page 319 and 320:

Pressure Equipment: Directives and

- Page 321 and 322:

Pressure Equipment: Directives and

- Page 323 and 324:

Pressure Equipment: Directives and

- Page 325 and 326:

322 Engineers’ Guide to Pressure

- Page 327 and 328:

324 Engineers’ Guide to Pressure

- Page 329 and 330:

326 Engineers’ Guide to Pressure

- Page 331 and 332:

328 Engineers’ Guide to Pressure

- Page 333 and 334:

330 Engineers’ Guide to Pressure

- Page 335 and 336:

332 Engineers’ Guide to Pressure

- Page 337 and 338:

334 TUV TUV (UK) Ltd Surrey House S

- Page 339 and 340:

336 Engineers’ Guide to Pressure

- Page 341 and 342:

Pressure [kPa] Temp. [°C] Specific

- Page 343 and 344:

31.19 70 0.0010228 5.0409772 5.042

- Page 345 and 346:

APPENDIX 2 Some European Notified B

- Page 347 and 348:

0045 TÜV Nord EV Grosse Bahnstrass

- Page 349 and 350:

0686 Zentrallabor der TOS E V - Zer

- Page 351 and 352:

Lloyd's Register Of Shipping 29 Wel

- Page 353 and 354:

APPENDIX 3 Standards and Directives

- Page 355 and 356:

Flanges and their joints - Circular

- Page 357 and 358:

Flanges and their joints - Gaskets

- Page 359 and 360:

Metallic industrial piping - Part 1

- Page 361 and 362:

Industrial valves - End-to-end and

- Page 363 and 364:

Shell boilers - Part 2: Materials f

- Page 365 and 366:

Water-tube boilers and auxiliary in

- Page 367 and 368:

Technical delivery conditions for s

- Page 369 and 370:

Subject Work item ID Butt welding p

- Page 371 and 372:

Non-destructive testing of steel tu

- Page 373 and 374:

Non-destructive testing of steel tu

- Page 375 and 376:

Pipework - Corrugated flexible meta

- Page 377 and 378:

Steel tubes, fittings and structura

- Page 379 and 380:

Flat products made of steels for pr

- Page 381 and 382:

Cold formed welded structural hollo

- Page 383 and 384:

Subject Work item ID Pressure regul

- Page 385 and 386:

Index Index Terms Links A ASME A st

- Page 387 and 388:

Index Terms Links C Canadian standa

- Page 389 and 390:

Index Terms Links Deaerator, contac

- Page 391 and 392:

Index Terms Links Fatigue (Continue

- Page 393 and 394:

Index Terms Links Internal energy 3

- Page 395 and 396:

Index Terms Links P Pads 33 PD 5500

- Page 397 and 398:

Index Terms Links R Radiographic te

- Page 399 and 400:

Index Terms Links Steel: alloy 185

- Page 401 and 402:

Index Terms Links Ultrasonic testin