Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

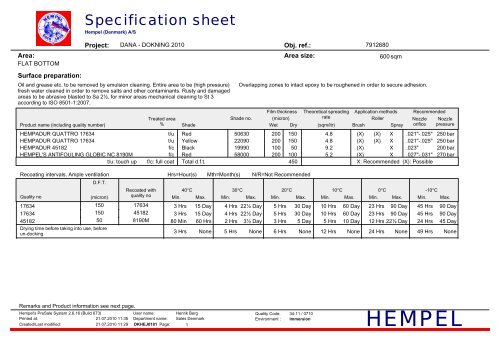

Area:<br />

FLAT BOTTOM<br />

Surface preparation:<br />

Specification sheet<br />

Hempel (Denmark) A/S<br />

Project:<br />

DANA - DOKNING 2010<br />

Oil and grease etc. to be removed by emulsion cleaning. Entire area to be (high pressure)<br />

fresh water cleaned in order to remove salts and other contaminants. Rusty and damaged<br />

areas to be abrasive blasted to Sa 2½, for minor areas mechanical cleaning to St 3<br />

according to ISO 8501-1:2007.<br />

Product name (including quality number)<br />

Treated area<br />

% Shade<br />

Obj. ref.: 7912680<br />

Area size:<br />

600 sqm<br />

Overlapping zones to intact epoxy to be roughened in order to secure adhesion.<br />

Shade no.<br />

Film thickness Theoretical spreading Application methods<br />

(micron)<br />

rate<br />

Roller<br />

Wet Dry (sqm/ltr) Brush<br />

Spray<br />

Recommended<br />

HEMPADUR QUATTRO 17634 t/u Red 50630 200 150 4.8 (X) (X) X .021"-.025" 250 bar<br />

HEMPADUR QUATTRO 17634 t/u Yellow 22090 200 150 4.8 (X) (X) X .021"-.025" 250 bar<br />

HEMPADUR 45182 f/c Black 19990 100 50 9.2 (X) X .023" 200 bar<br />

<strong>HEMPEL</strong>'S ANTIFOULING GLOBIC NC 8190M f/c Red 58000 200 100 5.2 (X) X .027"-.031" 270 bar<br />

t/u: touch up f/c: full coat Total d.f.t. 450 X: Recommended (X): Possible<br />

Recoating intervals. Ample ventilation Hrs=Hour(s) Mth=Month(s) N/R=Not Recommended<br />

Quality no<br />

D.F.T.<br />

(micron)<br />

17634<br />

150<br />

17634<br />

150<br />

45182<br />

50<br />

Drying time before taking into use, before<br />

un-docking<br />

Remarks and Product information see next page.<br />

Recoated with<br />

quality no<br />

17634<br />

45182<br />

8190M<br />

Nozzle<br />

orifice<br />

40°C 30°C 20°C 10°C 0°C -10°C<br />

Nozzle<br />

pressure<br />

Min. Max. Min. Max. Min. Max. Min. Max. Min. Max. Min. Max.<br />

3 Hrs 15 Day 4 Hrs 22½ Day 5 Hrs 30 Day 10 Hrs 60 Day 23 Hrs 90 Day 45 Hrs 90 Day<br />

3 Hrs 15 Day 4 Hrs 22½ Day 5 Hrs 30 Day 10 Hrs 60 Day 23 Hrs 90 Day 45 Hrs 90 Day<br />

80 Min 60 Hrs 2 Hrs 3½ Day 3 Hrs 5 Day 5 Hrs 10 Day 12 Hrs 22½ Day 24 Hrs 45 Day<br />

Hempel's PreSale System 2.6.16 (Build 673)<br />

User name:<br />

Henrik Berg<br />

Quality Code: 34-11 / 0710<br />

Printed at: 21.07.2010 11:35 Department name: Sales Denmark Environment : Immersion<br />

Created/Last modified: 21.07.2010 11:29 DKHEJ0181 Page: 1<br />

3 Hrs None 5 Hrs None 6 Hrs None 12 Hrs None 24 Hrs None 49 Hrs None<br />

<strong>HEMPEL</strong>

Area:<br />

FLAT BOTTOM<br />

Remarks:<br />

Specification sheet<br />

Hempel (Denmark) A/S<br />

Project:<br />

DANA - DOKNING 2010<br />

Obj. ref.: 7912680<br />

Area size:<br />

600 sqm<br />

The surface must be completely clean and dry with a temperature 3°C/5°F above the dew point to avoid condensation.<br />

Normal good painting practice must be followed throughout the entire painting procedure.<br />

Consult the separate APPLICATION INSTRUCTIONS for HEMPADUR QUATTRO 17634.<br />

The designed performance of the antifouling can only be achieved when it is applied at the specified film thickness as a minimum. The antifouling is to be applied by airless spray<br />

equipment. It is recommended to use cross spray technique.<br />

The specified high film thickness can best be obtained by airless spray application. If another application method is used more applications are necessary to achieve the specified dry<br />

film thickness.<br />

Product information:<br />

Mixing ratio Pot life Dry to touch Flash<br />

Application restrictions<br />

Shade no.<br />

Volume<br />

solids %<br />

Curing<br />

agent<br />

volume<br />

20°C 20°C<br />

point<br />

°C<br />

VOC<br />

g/ltr MAL Thinner<br />

Min. Temp. Max. RH%<br />

°C<br />

HEMPADUR QUATTRO 17634 50630 72 97334 4 : 1 2 h 4 h 27 275 4-5 08450 -10<br />

HEMPADUR QUATTRO 17634 22090 72 97334 4 : 1 2 h 4 h 27 270 4-5 08450 -10<br />

HEMPADUR 45182 19990 46 98180 4 : 1 3 h 6 h 23 482 4-5 08450 -10<br />

<strong>HEMPEL</strong>'S ANTIFOULING GLOBIC NC<br />

8190M<br />

58000 52 4 h 27 430 08080 3-6<br />

The data, specifications, directions and recommendations (hereinafter "Information") given in this painting specification are based upon test results obtained under controlled or specifically defined conditions and said Information is correct to the<br />

best of our knowledge. The User must satisfy itself that it is appropriate to use the Product in accordance with the Information in the actual conditions under which the Product is intended to be used, and the Manufacturer and Seller do not<br />

guarantee the accuracy, completeness or appropriateness of the Information when the Product is used in those conditions. The provisions of Clause 8 of the GENERAL CONDITIONS OF SALE, DELIVERY AND SERVICE shall apply to any and<br />

all claims arising out of or in connection with the use of the Product as recommended above, overleaf or otherwise.<br />

Hempel's PreSale System 2.6.16 (Build 673)<br />

User name:<br />

Henrik Berg<br />

Quality Code: 34-11 / 0710<br />

<strong>HEMPEL</strong><br />

Printed at: 21.07.2010 11:35 Department name: Sales Denmark Environment : Immersion<br />

Created/Last modified: 21.07.2010 11:29 DKHEJ0181 Page: 2

Area:<br />

VERTICAL BOTTOM<br />

Surface preparation:<br />

Specification sheet<br />

Hempel (Denmark) A/S<br />

Project:<br />

DANA - DOKNING 2010<br />

Oil and grease etc. to be removed by emulsion cleaning. Entire area to be (high pressure)<br />

fresh water cleaned in order to remove salts and other contaminants. Rusty and damaged<br />

areas to be abrasive blasted to Sa 2½, for minor areas mechanical cleaning to St 3<br />

according to ISO 8501-1:2007.<br />

Product name (including quality number)<br />

Treated area<br />

% Shade<br />

Obj. ref.: 7912680<br />

Area size:<br />

825 sqm<br />

Overlapping zones to intact epoxy to be roughened in order to secure adhesion.<br />

Shade no.<br />

Film thickness Theoretical spreading Application methods<br />

(micron)<br />

rate<br />

Roller<br />

Wet Dry (sqm/ltr) Brush<br />

Spray<br />

Recommended<br />

HEMPADUR QUATTRO 17634 t/u Red 50630 200 150 4.8 (X) (X) X .021"-.025" 250 bar<br />

HEMPADUR QUATTRO 17634 t/u Yellow 22090 200 150 4.8 (X) (X) X .021"-.025" 250 bar<br />

HEMPADUR 45182 f/c Black 19990 100 50 9.2 (X) X .023" 200 bar<br />

<strong>HEMPEL</strong>'S ANTIFOULING GLOBIC NC 8190M f/c Red 58000 300 150 3.5 (X) X .027"-.031" 270 bar<br />

t/u: touch up f/c: full coat Total d.f.t. 500 X: Recommended (X): Possible<br />

Recoating intervals. Ample ventilation Hrs=Hour(s) Mth=Month(s) N/R=Not Recommended<br />

Quality no<br />

D.F.T.<br />

(micron)<br />

17634<br />

150<br />

17634<br />

150<br />

45182<br />

50<br />

Drying time before taking into use, before<br />

un-docking<br />

Remarks and Product information see next page.<br />

Recoated with<br />

quality no<br />

17634<br />

45182<br />

8190M<br />

Nozzle<br />

orifice<br />

40°C 30°C 20°C 10°C 0°C -10°C<br />

Nozzle<br />

pressure<br />

Min. Max. Min. Max. Min. Max. Min. Max. Min. Max. Min. Max.<br />

3 Hrs 15 Day 4 Hrs 22½ Day 5 Hrs 30 Day 10 Hrs 60 Day 23 Hrs 90 Day 45 Hrs 90 Day<br />

3 Hrs 15 Day 4 Hrs 22½ Day 5 Hrs 30 Day 10 Hrs 60 Day 23 Hrs 90 Day 45 Hrs 90 Day<br />

80 Min 60 Hrs 2 Hrs 3½ Day 3 Hrs 5 Day 5 Hrs 10 Day 12 Hrs 22½ Day 24 Hrs 45 Day<br />

Hempel's PreSale System 2.6.16 (Build 673)<br />

User name:<br />

Henrik Berg<br />

Quality Code: 34-11 / 0710<br />

Printed at: 21.07.2010 11:35 Department name: Sales Denmark Environment : Immersion<br />

Created/Last modified: 21.07.2010 11:29 DKHEJ0181 Page: 3<br />

5 Hrs None 8 Hrs None 10 Hrs None 21 Hrs None 42 Hrs None 3½ Day None<br />

<strong>HEMPEL</strong>

Area:<br />

VERTICAL BOTTOM<br />

Remarks:<br />

Specification sheet<br />

Hempel (Denmark) A/S<br />

Project:<br />

DANA - DOKNING 2010<br />

Obj. ref.: 7912680<br />

Area size:<br />

825 sqm<br />

The surface must be completely clean and dry with a temperature 3°C/5°F above the dew point to avoid condensation.<br />

Normal good painting practice must be followed throughout the entire painting procedure.<br />

Consult the separate APPLICATION INSTRUCTIONS for HEMPADUR QUATTRO 17634.<br />

The designed performance of the antifouling can only be achieved when it is applied at the specified film thickness as a minimum. The antifouling is to be applied by airless spray<br />

equipment. It is recommended to use cross spray technique.<br />

With this one coat antifouling system it is of vital importance that the specified dry filmthickness as a minimum is achieved.<br />

The specified high film thickness can best be obtained by airless spray application. If another application method is used more applications are necessary to achieve the specified dry<br />

film thickness.<br />

All other paint work on exterior hull surfaces must be completed before start on the first coat of antifouling to avoid overspray and spray dust on the antifouling.<br />

Alternatively protect the antifouling with a coat of water soluble wall paper paste approved for this purpose.<br />

Product information:<br />

Mixing ratio Pot life Dry to touch Flash<br />

Application restrictions<br />

Shade no.<br />

Volume<br />

solids %<br />

Curing<br />

agent<br />

volume<br />

20°C 20°C<br />

point<br />

°C<br />

VOC<br />

g/ltr MAL Thinner<br />

Min. Temp. Max. RH%<br />

°C<br />

HEMPADUR QUATTRO 17634 50630 72 97334 4 : 1 2 h 4 h 27 275 4-5 08450 -10<br />

HEMPADUR QUATTRO 17634 22090 72 97334 4 : 1 2 h 4 h 27 270 4-5 08450 -10<br />

HEMPADUR 45182 19990 46 98180 4 : 1 3 h 6 h 23 482 4-5 08450 -10<br />

<strong>HEMPEL</strong>'S ANTIFOULING GLOBIC NC<br />

8190M<br />

58000 52 4 h 27 430 08080 3-6<br />

The data, specifications, directions and recommendations (hereinafter "Information") given in this painting specification are based upon test results obtained under controlled or specifically defined conditions and said Information is correct to the<br />

best of our knowledge. The User must satisfy itself that it is appropriate to use the Product in accordance with the Information in the actual conditions under which the Product is intended to be used, and the Manufacturer and Seller do not<br />

guarantee the accuracy, completeness or appropriateness of the Information when the Product is used in those conditions. The provisions of Clause 8 of the GENERAL CONDITIONS OF SALE, DELIVERY AND SERVICE shall apply to any and<br />

all claims arising out of or in connection with the use of the Product as recommended above, overleaf or otherwise.<br />

Hempel's PreSale System 2.6.16 (Build 673)<br />

User name:<br />

Henrik Berg<br />

Quality Code: 34-11 / 0710<br />

<strong>HEMPEL</strong><br />

Printed at: 21.07.2010 11:35 Department name: Sales Denmark Environment : Immersion<br />

Created/Last modified: 21.07.2010 11:29 DKHEJ0181 Page: 4

Area:<br />

BALLAST TANKS<br />

Surface preparation:<br />

Specification sheet<br />

Hempel (Denmark) A/S<br />

Project:<br />

DANA - DOKNING 2010 Obj. ref.: 7912680<br />

Oil and grease etc. to be removed by emulsion cleaning. Entire area to be (high pressure)<br />

fresh water cleaned in order to remove salts and other contaminants. Abrasive blast to Sa<br />

2½ according to ISO 8501-1:2007. After full blasting minor areas may be mechanically<br />

prepared to St3.<br />

The water soluble salt limit equivalent to sodium chloride must not exceed 50 mg/m² on<br />

the prepared steel surfaces. Reference is made to the Application Instructions - Ballast<br />

Tanks.<br />

Product name (including quality number)<br />

Treated area<br />

% Shade<br />

Overlapping zones to intact epoxy to be roughened in order to secure adhesion.<br />

Shade no.<br />

Film thickness Theoretical spreading Application methods<br />

(micron)<br />

rate<br />

Roller<br />

Wet Dry (sqm/ltr) Brush<br />

Spray<br />

Recommended<br />

HEMPADUR QUATTRO 17634 t/u Red 50630 225 160 4.5 (X) (X) X .021"-.025" 250 bar<br />

HEMPADUR QUATTRO 17634 t/u Yellow 22090 225 160 4.5 (X) (X) X .021"-.025" 250 bar<br />

t/u: touch up f/c: full coat Total d.f.t. 320 X: Recommended (X): Possible<br />

Recoating intervals. Ample ventilation Hrs=Hour(s) Mth=Month(s) N/R=Not Recommended<br />

Quality no<br />

17634<br />

D.F.T.<br />

(micron)<br />

160<br />

Remarks and Product information see next page.<br />

Recoated with<br />

quality no<br />

17634<br />

Nozzle<br />

orifice<br />

40°C 30°C 20°C 10°C 0°C -10°C<br />

Nozzle<br />

pressure<br />

Min. Max. Min. Max. Min. Max. Min. Max. Min. Max. Min. Max.<br />

Hempel's PreSale System 2.6.16 (Build 673)<br />

User name:<br />

Henrik Berg<br />

Quality Code: 34-11 / 0710<br />

Printed at: 21.07.2010 11:35 Department name: Sales Denmark Environment : Immersion<br />

Created/Last modified: 21.07.2010 11:29 DKHEJ0181 Page: 5<br />

3 Hrs 15 Day 4 Hrs 22½ Day 5 Hrs 30 Day 11 Hrs 60 Day 25 Hrs 90 Day 49 Hrs 90 Day<br />

<strong>HEMPEL</strong>

Area:<br />

BALLAST TANKS<br />

Remarks:<br />

Specification sheet<br />

Hempel (Denmark) A/S<br />

Project:<br />

DANA - DOKNING 2010 Obj. ref.: 7912680<br />

The surface must be completely clean and dry with a temperature 3°C/5°F above the dew point to avoid condensation.<br />

At the freezing point be aware of ice on the surface.<br />

The specified high film thickness can best be obtained by airless spray application. If another application method is used more applications are necessary to achieve the specified dry<br />

film thickness.<br />

Curing agent 97334 is hazy. This is intended and has no influence on the performance.<br />

With this ballast tank coating system it is especially important that the specified film thickness is achieved all over and that a uniform film formation free of any pinholes and other<br />

defects is obtained for each coat applied.<br />

Stripe coating with brush before or after spray application of each coat is to be carried out on areas difficult to cover properly by spray such as edges, corners, flanges, cutouts,<br />

handwelds and other rough surfaces. IMO MSC.215(82) accepts roller application on scallops, ratholes, etc. only.<br />

If the maximum recoating interval is exceeded, roughening of the surface is necessary to ensure intercoat adhesion.<br />

In confined spaces provide adequate ventilation during application and drying.<br />

Before taking tank into use, allow paint film to dry and cure completely (including several days by strong ventilation).<br />

Product information:<br />

Mixing ratio Pot life Dry to touch Flash<br />

Application restrictions<br />

Shade no.<br />

Volume<br />

solids %<br />

Curing<br />

agent<br />

volume<br />

20°C 20°C<br />

point<br />

°C<br />

VOC<br />

g/ltr MAL Thinner<br />

Min. Temp. Max. RH%<br />

°C<br />

HEMPADUR QUATTRO 17634 50630 72 97334 4 : 1 2 h 4 h 27 275 4-5 08450 -10<br />

HEMPADUR QUATTRO 17634 22090 72 97334 4 : 1 2 h 4 h 27 270 4-5 08450 -10<br />

The data, specifications, directions and recommendations (hereinafter "Information") given in this painting specification are based upon test results obtained under controlled or specifically defined conditions and said Information is correct to the<br />

best of our knowledge. The User must satisfy itself that it is appropriate to use the Product in accordance with the Information in the actual conditions under which the Product is intended to be used, and the Manufacturer and Seller do not<br />

guarantee the accuracy, completeness or appropriateness of the Information when the Product is used in those conditions. The provisions of Clause 8 of the GENERAL CONDITIONS OF SALE, DELIVERY AND SERVICE shall apply to any and<br />

all claims arising out of or in connection with the use of the Product as recommended above, overleaf or otherwise.<br />

Hempel's PreSale System 2.6.16 (Build 673)<br />

User name:<br />

Henrik Berg<br />

Quality Code: 34-11 / 0710<br />

<strong>HEMPEL</strong><br />

Printed at: 21.07.2010 11:35 Department name: Sales Denmark Environment : Immersion<br />

Created/Last modified: 21.07.2010 11:29 DKHEJ0181 Page: 6

Area:<br />

CHAIN LOCKER<br />

Surface preparation:<br />

Specification sheet<br />

Hempel (Denmark) A/S<br />

Project:<br />

DANA - DOKNING 2010 Obj. ref.: 7912680<br />

Oil and grease etc. to be removed by emulsion cleaning. Entire area to be (high pressure)<br />

fresh water cleaned in order to remove salts and other contaminants. Rusty and damaged<br />

areas to be mechanical cleaned to St 3 according to ISO 8501-1:2007.<br />

Product name (including quality number)<br />

Treated area<br />

% Shade<br />

Shade no.<br />

Film thickness Theoretical spreading Application methods<br />

(micron)<br />

rate<br />

Roller<br />

Wet Dry (sqm/ltr) Brush<br />

Spray<br />

Recommended<br />

HEMPINOL 10220 t/u Black 19990 300 175 3.3 X X .021"-.025" 200 bar<br />

t/u: touch up f/c: full coat Total d.f.t. 175 X: Recommended (X): Possible<br />

Remarks and Product information see next page.<br />

Hempel's PreSale System 2.6.16 (Build 673)<br />

User name:<br />

Henrik Berg<br />

Quality Code: 34-11 / 0710<br />

Printed at: 21.07.2010 11:35 Department name: Sales Denmark Environment : Medium<br />

Created/Last modified: 21.07.2010 11:29 DKHEJ0181 Page: 7<br />

Nozzle<br />

orifice<br />

Nozzle<br />

pressure<br />

<strong>HEMPEL</strong>

Area:<br />

CHAIN LOCKER<br />

Remarks:<br />

Specification sheet<br />

Hempel (Denmark) A/S<br />

Project:<br />

DANA - DOKNING 2010 Obj. ref.: 7912680<br />

The surface must be completely clean and dry with a temperature 3°C/5°F above the dew point to avoid condensation.<br />

Normal good painting practice must be followed throughout the entire painting procedure.<br />

The specified high film thickness can best be obtained by airless spray application. If another application method is used more applications are necessary to achieve the specified dry<br />

film thickness.<br />

Stripe coating with brush is recommended on areas difficult to cover properly by spray as eg edges, corners, flanges, cutouts, handwelds and other rough surfaces.<br />

Product information:<br />

Mixing ratio Pot life Dry to touch Flash<br />

Application restrictions<br />

Shade no.<br />

Volume<br />

solids %<br />

Curing<br />

agent<br />

volume<br />

20°C 20°C<br />

point<br />

°C<br />

VOC<br />

g/ltr MAL Thinner<br />

Min. Temp. Max. RH%<br />

°C<br />

HEMPINOL 10220 19990 57 16 h 38 340 08080 2-1<br />

The data, specifications, directions and recommendations (hereinafter "Information") given in this painting specification are based upon test results obtained under controlled or specifically defined conditions and said Information is correct to the<br />

best of our knowledge. The User must satisfy itself that it is appropriate to use the Product in accordance with the Information in the actual conditions under which the Product is intended to be used, and the Manufacturer and Seller do not<br />

guarantee the accuracy, completeness or appropriateness of the Information when the Product is used in those conditions. The provisions of Clause 8 of the GENERAL CONDITIONS OF SALE, DELIVERY AND SERVICE shall apply to any and<br />

all claims arising out of or in connection with the use of the Product as recommended above, overleaf or otherwise.<br />

Hempel's PreSale System 2.6.16 (Build 673)<br />

User name:<br />

Henrik Berg<br />

Quality Code: 34-11 / 0710<br />

<strong>HEMPEL</strong><br />

Printed at: 21.07.2010 11:35 Department name: Sales Denmark Environment : Medium<br />

Created/Last modified: 21.07.2010 11:29 DKHEJ0181 Page: 8

Area:<br />

FOREPEAK TANK<br />

Surface preparation:<br />

Specification sheet<br />

Hempel (Denmark) A/S<br />

Project:<br />

DANA - DOKNING 2010 Obj. ref.: 7912680<br />

Oil and grease etc. to be removed by emulsion cleaning. Entire area to be (high pressure)<br />

fresh water cleaned in order to remove salts and other contaminants. Rusty and damaged<br />

areas to be mechanical cleaned to St 3 according to ISO 8501-1:2007.<br />

Product name (including quality number)<br />

Treated area<br />

% Shade<br />

Shade no.<br />

Film thickness Theoretical spreading Application methods<br />

(micron)<br />

rate<br />

Roller<br />

Wet Dry (sqm/ltr) Brush<br />

Spray<br />

Recommended<br />

HEMPINOL 10220 t/u Black 19990 300 175 3.3 X X .021"-.025" 200 bar<br />

t/u: touch up f/c: full coat Total d.f.t. 175 X: Recommended (X): Possible<br />

Remarks and Product information see next page.<br />

Hempel's PreSale System 2.6.16 (Build 673)<br />

User name:<br />

Henrik Berg<br />

Quality Code: 34-11 / 0710<br />

Printed at: 21.07.2010 11:35 Department name: Sales Denmark Environment : Immersion<br />

Created/Last modified: 21.07.2010 11:29 DKHEJ0181 Page: 9<br />

Nozzle<br />

orifice<br />

Nozzle<br />

pressure<br />

<strong>HEMPEL</strong>

Area:<br />

FOREPEAK TANK<br />

Remarks:<br />

Specification sheet<br />

Hempel (Denmark) A/S<br />

Project:<br />

DANA - DOKNING 2010 Obj. ref.: 7912680<br />

The surface must be completely clean and dry with a temperature 3°C/5°F above the dew point to avoid condensation.<br />

Normal good painting practice must be followed throughout the entire painting procedure.<br />

The specified high film thickness can best be obtained by airless spray application. If another application method is used more applications are necessary to achieve the specified dry<br />

film thickness.<br />

Stripe coating with brush is recommended on areas difficult to cover properly by spray as eg edges, corners, flanges, cutouts, handwelds and other rough surfaces.<br />

Product information:<br />

Mixing ratio Pot life Dry to touch Flash<br />

Application restrictions<br />

Shade no.<br />

Volume<br />

solids %<br />

Curing<br />

agent<br />

volume<br />

20°C 20°C<br />

point<br />

°C<br />

VOC<br />

g/ltr MAL Thinner<br />

Min. Temp. Max. RH%<br />

°C<br />

HEMPINOL 10220 19990 57 16 h 38 340 08080 2-1<br />

The data, specifications, directions and recommendations (hereinafter "Information") given in this painting specification are based upon test results obtained under controlled or specifically defined conditions and said Information is correct to the<br />

best of our knowledge. The User must satisfy itself that it is appropriate to use the Product in accordance with the Information in the actual conditions under which the Product is intended to be used, and the Manufacturer and Seller do not<br />

guarantee the accuracy, completeness or appropriateness of the Information when the Product is used in those conditions. The provisions of Clause 8 of the GENERAL CONDITIONS OF SALE, DELIVERY AND SERVICE shall apply to any and<br />

all claims arising out of or in connection with the use of the Product as recommended above, overleaf or otherwise.<br />

Hempel's PreSale System 2.6.16 (Build 673)<br />

User name:<br />

Henrik Berg<br />

Quality Code: 34-11 / 0710<br />

<strong>HEMPEL</strong><br />

Printed at: 21.07.2010 11:35 Department name: Sales Denmark Environment : Immersion<br />

Created/Last modified: 21.07.2010 11:29 DKHEJ0181 Page: 10

Specification sheet<br />

Hempel (Denmark) A/S<br />

Project:<br />

Area:<br />

SEPTIC TANK, ( EXCISTING TANK)<br />

Surface preparation:<br />

DANA - DOKNING 2010 Obj. ref.: 7912680<br />

Oil and grease etc. to be removed by emulsion cleaning. Entire area to be (high pressure)<br />

fresh water cleaned in order to remove salts and other contaminants. Rusty and damaged<br />

areas to be mechanical cleaned to St 3 according to ISO 8501-1:2007.<br />

Product name (including quality number)<br />

Treated area<br />

% Shade<br />

Shade no.<br />

Film thickness Theoretical spreading Application methods<br />

(micron)<br />

rate<br />

Roller<br />

Wet Dry (sqm/ltr) Brush<br />

Spray<br />

Recommended<br />

HEMPINOL 10220 t/u Black 19990 300 175 3.3 X X .021"-.025" 200 bar<br />

t/u: touch up f/c: full coat Total d.f.t. 175 X: Recommended (X): Possible<br />

Remarks and Product information see next page.<br />

Hempel's PreSale System 2.6.16 (Build 673)<br />

User name:<br />

Henrik Berg<br />

Quality Code: 34-11 / 0710<br />

Printed at: 21.07.2010 11:35 Department name: Sales Denmark Environment : Immersion<br />

Created/Last modified: 21.07.2010 11:29 DKHEJ0181 Page: 11<br />

Nozzle<br />

orifice<br />

Nozzle<br />

pressure<br />

<strong>HEMPEL</strong>

Specification sheet<br />

Hempel (Denmark) A/S<br />

Project:<br />

Area:<br />

SEPTIC TANK, ( EXCISTING TANK)<br />

Remarks:<br />

DANA - DOKNING 2010 Obj. ref.: 7912680<br />

The surface must be completely clean and dry with a temperature 3°C/5°F above the dew point to avoid condensation.<br />

Normal good painting practice must be followed throughout the entire painting procedure.<br />

The specified high film thickness can best be obtained by airless spray application. If another application method is used more applications are necessary to achieve the specified dry<br />

film thickness.<br />

Stripe coating with brush is recommended on areas difficult to cover properly by spray as eg edges, corners, flanges, cutouts, handwelds and other rough surfaces.<br />

Product information:<br />

Mixing ratio Pot life Dry to touch Flash<br />

Application restrictions<br />

Shade no.<br />

Volume<br />

solids %<br />

Curing<br />

agent<br />

volume<br />

20°C 20°C<br />

point<br />

°C<br />

VOC<br />

g/ltr MAL Thinner<br />

Min. Temp. Max. RH%<br />

°C<br />

HEMPINOL 10220 19990 57 16 h 38 340 08080 2-1<br />

The data, specifications, directions and recommendations (hereinafter "Information") given in this painting specification are based upon test results obtained under controlled or specifically defined conditions and said Information is correct to the<br />

best of our knowledge. The User must satisfy itself that it is appropriate to use the Product in accordance with the Information in the actual conditions under which the Product is intended to be used, and the Manufacturer and Seller do not<br />

guarantee the accuracy, completeness or appropriateness of the Information when the Product is used in those conditions. The provisions of Clause 8 of the GENERAL CONDITIONS OF SALE, DELIVERY AND SERVICE shall apply to any and<br />

all claims arising out of or in connection with the use of the Product as recommended above, overleaf or otherwise.<br />

Hempel's PreSale System 2.6.16 (Build 673)<br />

User name:<br />

Henrik Berg<br />

Quality Code: 34-11 / 0710<br />

<strong>HEMPEL</strong><br />

Printed at: 21.07.2010 11:35 Department name: Sales Denmark Environment : Immersion<br />

Created/Last modified: 21.07.2010 11:29 DKHEJ0181 Page: 12

Specification sheet<br />

Hempel (Denmark) A/S<br />

Project:<br />

Area:<br />

BALLAST TANKS BELOW SAUNA AND LAUNDRY<br />

Surface preparation:<br />

DANA - DOKNING 2010 Obj. ref.: 7912680<br />

Oil and grease etc. to be removed by emulsion cleaning. Entire area to be (high pressure)<br />

fresh water cleaned in order to remove salts and other contaminants. Abrasive blast to Sa<br />

2½ according to ISO 8501-1:2007. After full blasting minor areas may be mechanically<br />

prepared to St3.<br />

The water soluble salt limit equivalent to sodium chloride must not exceed 50 mg/m² on<br />

the prepared steel surfaces. Reference is made to the Application Instructions - Ballast<br />

Tanks.<br />

Product name (including quality number)<br />

Treated area<br />

% Shade<br />

Overlapping zones to intact epoxy to be roughened in order to secure adhesion.<br />

Shade no.<br />

Film thickness Theoretical spreading Application methods<br />

(micron)<br />

rate<br />

Roller<br />

Wet Dry (sqm/ltr) Brush<br />

Spray<br />

Recommended<br />

HEMPADUR QUATTRO 17634 t/u Red 50630 225 160 4.5 (X) (X) X .021"-.025" 250 bar<br />

HEMPADUR QUATTRO 17634 t/u Yellow 22090 225 160 4.5 (X) (X) X .021"-.025" 250 bar<br />

t/u: touch up f/c: full coat Total d.f.t. 320 X: Recommended (X): Possible<br />

Recoating intervals. Ample ventilation Hrs=Hour(s) Mth=Month(s) N/R=Not Recommended<br />

Quality no<br />

17634<br />

D.F.T.<br />

(micron)<br />

160<br />

Remarks and Product information see next page.<br />

Recoated with<br />

quality no<br />

17634<br />

Nozzle<br />

orifice<br />

40°C 30°C 20°C 10°C 0°C -10°C<br />

Nozzle<br />

pressure<br />

Min. Max. Min. Max. Min. Max. Min. Max. Min. Max. Min. Max.<br />

Hempel's PreSale System 2.6.16 (Build 673)<br />

User name:<br />

Henrik Berg<br />

Quality Code: 34-11 / 0710<br />

Printed at: 21.07.2010 11:35 Department name: Sales Denmark Environment : Immersion<br />

Created/Last modified: 21.07.2010 11:29 DKHEJ0181 Page: 13<br />

3 Hrs 15 Day 4 Hrs 22½ Day 5 Hrs 30 Day 11 Hrs 60 Day 25 Hrs 90 Day 49 Hrs 90 Day<br />

<strong>HEMPEL</strong>

Specification sheet<br />

Hempel (Denmark) A/S<br />

Project:<br />

Area:<br />

BALLAST TANKS BELOW SAUNA AND LAUNDRY<br />

Remarks:<br />

DANA - DOKNING 2010 Obj. ref.: 7912680<br />

The surface must be completely clean and dry with a temperature 3°C/5°F above the dew point to avoid condensation.<br />

At the freezing point be aware of ice on the surface.<br />

The specified high film thickness can best be obtained by airless spray application. If another application method is used more applications are necessary to achieve the specified dry<br />

film thickness.<br />

Curing agent 97334 is hazy. This is intended and has no influence on the performance.<br />

With this ballast tank coating system it is especially important that the specified film thickness is achieved all over and that a uniform film formation free of any pinholes and other<br />

defects is obtained for each coat applied.<br />

Stripe coating with brush before or after spray application of each coat is to be carried out on areas difficult to cover properly by spray such as edges, corners, flanges, cutouts,<br />

handwelds and other rough surfaces. IMO MSC.215(82) accepts roller application on scallops, ratholes, etc. only.<br />

If the maximum recoating interval is exceeded, roughening of the surface is necessary to ensure intercoat adhesion.<br />

In confined spaces provide adequate ventilation during application and drying.<br />

Before taking tank into use, allow paint film to dry and cure completely (including several days by strong ventilation).<br />

Product information:<br />

Mixing ratio Pot life Dry to touch Flash<br />

Application restrictions<br />

Shade no.<br />

Volume<br />

solids %<br />

Curing<br />

agent<br />

volume<br />

20°C 20°C<br />

point<br />

°C<br />

VOC<br />

g/ltr MAL Thinner<br />

Min. Temp. Max. RH%<br />

°C<br />

HEMPADUR QUATTRO 17634 50630 72 97334 4 : 1 2 h 4 h 27 275 4-5 08450 -10<br />

HEMPADUR QUATTRO 17634 22090 72 97334 4 : 1 2 h 4 h 27 270 4-5 08450 -10<br />

The data, specifications, directions and recommendations (hereinafter "Information") given in this painting specification are based upon test results obtained under controlled or specifically defined conditions and said Information is correct to the<br />

best of our knowledge. The User must satisfy itself that it is appropriate to use the Product in accordance with the Information in the actual conditions under which the Product is intended to be used, and the Manufacturer and Seller do not<br />

guarantee the accuracy, completeness or appropriateness of the Information when the Product is used in those conditions. The provisions of Clause 8 of the GENERAL CONDITIONS OF SALE, DELIVERY AND SERVICE shall apply to any and<br />

all claims arising out of or in connection with the use of the Product as recommended above, overleaf or otherwise.<br />

Hempel's PreSale System 2.6.16 (Build 673)<br />

User name:<br />

Henrik Berg<br />

Quality Code: 34-11 / 0710<br />

<strong>HEMPEL</strong><br />

Printed at: 21.07.2010 11:35 Department name: Sales Denmark Environment : Immersion<br />

Created/Last modified: 21.07.2010 11:29 DKHEJ0181 Page: 14

Specification sheet<br />

Hempel (Denmark) A/S<br />

Project:<br />

Area:<br />

ACCOMODATION INTERNAL AREAS, NEW STEEL<br />

Surface preparation:<br />

DANA - DOKNING 2010 Obj. ref.: 7912680<br />

Oil and grease etc. to be removed by emulsion cleaning. Entire area to be (high pressure)<br />

fresh water cleaned in order to remove salts and other contaminants. Rusty and damaged<br />

areas to be mechanical cleaned to St 3 according to ISO 8501-1:2007.<br />

Product name (including quality number)<br />

Treated area<br />

% Shade<br />

Shade no.<br />

Film thickness Theoretical spreading Application methods<br />

(micron)<br />

rate<br />

Roller<br />

Wet Dry (sqm/ltr) Brush<br />

Spray<br />

Recommended<br />

HEMPALIN PRIMER HI-BUILD 13200 t/u White 10000 150 75 6.3 (X) X .021"-.023" 200 bar<br />

HEMPALIN ENAMEL 52140 t/u To shade 99990 75 30 15.3 (X) (X) X .018" 150 bar<br />

t/u: touch up f/c: full coat Total d.f.t. 105 X: Recommended (X): Possible<br />

Recoating intervals. Ample ventilation Hrs=Hour(s) Mth=Month(s) N/R=Not Recommended<br />

Quality no<br />

13200<br />

D.F.T.<br />

(micron)<br />

75<br />

Remarks and Product information see next page.<br />

Recoated with<br />

quality no<br />

52140<br />

Nozzle<br />

orifice<br />

40°C 30°C 20°C 10°C 0°C -10°C<br />

Nozzle<br />

pressure<br />

Min. Max. Min. Max. Min. Max. Min. Max. Min. Max. Min. Max.<br />

Hempel's PreSale System 2.6.16 (Build 673)<br />

User name:<br />

Henrik Berg<br />

Quality Code: 34-11 / 0710<br />

Printed at: 21.07.2010 11:35 Department name: Sales Denmark Environment : Mild<br />

Created/Last modified: 21.07.2010 11:29 DKHEJ0181 Page: 15<br />

3 Hrs None 4 Hrs None 5 Hrs None 10 Hrs None N/R N/R N/R N/R<br />

<strong>HEMPEL</strong>

Specification sheet<br />

Hempel (Denmark) A/S<br />

Project:<br />

Area:<br />

ACCOMODATION INTERNAL AREAS, NEW STEEL<br />

Remarks:<br />

DANA - DOKNING 2010 Obj. ref.: 7912680<br />

Normal good painting practice must be followed throughout the entire painting procedure.<br />

The specified high film thickness can best be obtained by airless spray application. If another application method is used more applications are necessary to achieve the specified dry<br />

film thickness.<br />

Product information:<br />

Mixing ratio Pot life Dry to touch Flash<br />

Application restrictions<br />

Shade no.<br />

Volume<br />

solids %<br />

Curing<br />

agent<br />

volume<br />

20°C 20°C<br />

point<br />

°C<br />

VOC<br />

g/ltr MAL Thinner<br />

Min. Temp. Max. RH%<br />

°C<br />

HEMPALIN PRIMER HI-BUILD 13200 10000 47 4 h 38 409 08080 5 2-1<br />

HEMPALIN ENAMEL 52140 99990 46 6 h 38 430 08230 5 3-3<br />

The data, specifications, directions and recommendations (hereinafter "Information") given in this painting specification are based upon test results obtained under controlled or specifically defined conditions and said Information is correct to the<br />

best of our knowledge. The User must satisfy itself that it is appropriate to use the Product in accordance with the Information in the actual conditions under which the Product is intended to be used, and the Manufacturer and Seller do not<br />

guarantee the accuracy, completeness or appropriateness of the Information when the Product is used in those conditions. The provisions of Clause 8 of the GENERAL CONDITIONS OF SALE, DELIVERY AND SERVICE shall apply to any and<br />

all claims arising out of or in connection with the use of the Product as recommended above, overleaf or otherwise.<br />

Hempel's PreSale System 2.6.16 (Build 673)<br />

User name:<br />

Henrik Berg<br />

Quality Code: 34-11 / 0710<br />

<strong>HEMPEL</strong><br />

Printed at: 21.07.2010 11:35 Department name: Sales Denmark Environment : Mild<br />

Created/Last modified: 21.07.2010 11:29 DKHEJ0181 Page: 16

Area:<br />

STERN<br />

Surface preparation:<br />

Specification sheet<br />

Hempel (Denmark) A/S<br />

Project:<br />

DANA - DOKNING 2010<br />

Oil and grease etc. to be removed by emulsion cleaning. Entire area to be (high pressure)<br />

fresh water cleaned in order to remove salts and other contaminants. Damaged areas to<br />

be cleaned thoroughly by power tool cleaning to St 3 (spot-repairs) or abrasive blasting to<br />

min. Sa 2, preferably Sa 2½. Improved surface preparation will improve the performance<br />

of the paint system. Feather edges to sound and intact areas. Dust off residues.<br />

Product name (including quality number)<br />

Treated area<br />

% Shade<br />

Obj. ref.: 7912680<br />

Area size:<br />

250 sqm<br />

Overlapping zones to intact epoxy to be roughened in order to secure adhesion.<br />

Shade no.<br />

Film thickness Theoretical spreading Application methods<br />

(micron)<br />

rate<br />

Roller<br />

Wet Dry (sqm/ltr) Brush<br />

Spray<br />

Recommended<br />

HEMPADUR QUATTRO 17634 40 Red 50630 175 125 5.8 (X) (X) X .021"-.025" 250 bar<br />

HEMPADUR QUATTRO 17634 40 Yellow 22090 175 125 5.8 (X) (X) X .021"-.025" 250 bar<br />

HEMPATHANE TOPCOAT 55210 f/c Blue 30840 100 50 10.0 (X) (X) X .017"-.019" 150 bar<br />

t/u: touch up f/c: full coat Total d.f.t. 300 X: Recommended (X): Possible<br />

Recoating intervals. Ample ventilation Hrs=Hour(s) Mth=Month(s) N/R=Not Recommended<br />

Quality no<br />

17634<br />

17634<br />

D.F.T.<br />

(micron)<br />

125<br />

125<br />

Remarks and Product information see next page.<br />

Recoated with<br />

quality no<br />

17634<br />

55210<br />

Nozzle<br />

orifice<br />

40°C 30°C 20°C 10°C 0°C -10°C<br />

Nozzle<br />

pressure<br />

Min. Max. Min. Max. Min. Max. Min. Max. Min. Max. Min. Max.<br />

Hempel's PreSale System 2.6.16 (Build 673)<br />

User name:<br />

Henrik Berg<br />

Quality Code: 34-11 / 0710<br />

Printed at: 21.07.2010 11:35 Department name: Sales Denmark Environment : Medium<br />

Created/Last modified: 21.07.2010 11:29 DKHEJ0181 Page: 17<br />

1 Hrs None 90 Min None 2 Hrs None 4 Hrs None 9 Hrs None 18 Hrs None<br />

1 Hrs 10 Day 90 Min 15 Day 2 Hrs 20 Day 4 Hrs 40 Day 9 Hrs 90 Day 18 Hrs 90 Day<br />

<strong>HEMPEL</strong>

Area:<br />

STERN<br />

Remarks:<br />

Specification sheet<br />

Hempel (Denmark) A/S<br />

Project:<br />

DANA - DOKNING 2010<br />

Obj. ref.: 7912680<br />

Area size:<br />

250 sqm<br />

The surface must be completely clean and dry with a temperature 3°C/5°F above the dew point to avoid condensation.<br />

If the working procedure calls for a blast primer then use a thinned version of HEMPADUR QUATTRO in 40 - 50 microns dft.<br />

The specified high film thickness can best be obtained by airless spray application. If another application method is used more applications are necessary to achieve the specified dry<br />

film thickness.<br />

Pit-corroded areas may call for an extra coat to fill out pittings.<br />

Consult the separate APPLICATION INSTRUCTIONS for HEMPADUR QUATTRO 17634.<br />

If the maximum recoating interval is exceeded, roughening of the surface is necessary to ensure intercoat adhesion.<br />

Before recoating after exposure in contaminated environments, clean the surface thoroughly by (high pressure) fresh water hosing and allow to dry.<br />

Curing agent 97334 is hazy. This is intended and has no influence on the performance.<br />

Product information:<br />

Mixing ratio Pot life Dry to touch Flash<br />

Application restrictions<br />

Shade no.<br />

Volume<br />

solids %<br />

Curing<br />

agent<br />

volume<br />

20°C 20°C<br />

point<br />

°C<br />

VOC<br />

g/ltr MAL Thinner<br />

Min. Temp. Max. RH%<br />

°C<br />

HEMPADUR QUATTRO 17634 50630 72 97334 4 : 1 2 h 4 h 27 275 4-5 08450 -10<br />

HEMPADUR QUATTRO 17634 22090 72 97334 4 : 1 2 h 4 h 27 270 4-5 08450 -10<br />

HEMPATHANE TOPCOAT 55210 30840 50 95370 7 : 1 4 h 8 h 33 446 4-3 08080 -10<br />

The data, specifications, directions and recommendations (hereinafter "Information") given in this painting specification are based upon test results obtained under controlled or specifically defined conditions and said Information is correct to the<br />

best of our knowledge. The User must satisfy itself that it is appropriate to use the Product in accordance with the Information in the actual conditions under which the Product is intended to be used, and the Manufacturer and Seller do not<br />

guarantee the accuracy, completeness or appropriateness of the Information when the Product is used in those conditions. The provisions of Clause 8 of the GENERAL CONDITIONS OF SALE, DELIVERY AND SERVICE shall apply to any and<br />

all claims arising out of or in connection with the use of the Product as recommended above, overleaf or otherwise.<br />

Hempel's PreSale System 2.6.16 (Build 673)<br />

User name:<br />

Henrik Berg<br />

Quality Code: 34-11 / 0710<br />

<strong>HEMPEL</strong><br />

Printed at: 21.07.2010 11:35 Department name: Sales Denmark Environment : Medium<br />

Created/Last modified: 21.07.2010 11:29 DKHEJ0181 Page: 18

Area:<br />

AFT DECK<br />

Surface preparation:<br />

Specification sheet<br />

Hempel (Denmark) A/S<br />

Project:<br />

DANA - DOKNING 2010<br />

Oil and grease etc. to be removed by emulsion cleaning. Entire area to be (high pressure)<br />

fresh water cleaned in order to remove salts and other contaminants. When the surface is<br />

dry: Abrasive blasting to minimum Sa 2½ according to ISO 8501-1:2007 with a surface<br />

profile corresponding to Rugotest No. 3 BN 9a.<br />

Product name (including quality number)<br />

Treated area<br />

% Shade<br />

Obj. ref.: 7912680<br />

Area size:<br />

300 sqm<br />

Overlapping zones to intact layer to be roughened in order to secure adhesion.<br />

Shade no.<br />

Film thickness Theoretical spreading Application methods<br />

(micron)<br />

rate<br />

Roller<br />

Wet Dry (sqm/ltr) Brush<br />

Spray<br />

Recommended<br />

<strong>HEMPEL</strong>'S ZINC PRIMER 16490 60 Metal grey 19840 100 35 9.4 (X) X .019"-.021" 200 bar<br />

HEMPATEX HI-BUILD 46410 60 Red 50630 250 100 4.2 (X) (X) X .017"-.021" 175 bar<br />

HEMPATEX HI-BUILD 46410 60 Green 40640 225 100 4.3 (X) (X) X .017"-.021" 175 bar<br />

HEMPATEX ENAMEL 56360 f/c Green 40640 125 35 8.6 (X) (X) X .017" 150 bar<br />

t/u: touch up f/c: full coat Total d.f.t. 270 X: Recommended (X): Possible<br />

Recoating intervals. Ample ventilation Hrs=Hour(s) Mth=Month(s) N/R=Not Recommended<br />

Quality no<br />

16490<br />

46410<br />

46410<br />

D.F.T.<br />

(micron)<br />

35<br />

100<br />

100<br />

Remarks and Product information see next page.<br />

Recoated with<br />

quality no<br />

46410<br />

46410<br />

56360<br />

Nozzle<br />

orifice<br />

40°C 30°C 20°C 10°C 0°C -10°C<br />

Nozzle<br />

pressure<br />

Min. Max. Min. Max. Min. Max. Min. Max. Min. Max. Min. Max.<br />

15 Min None 25 Min None 30 Min None 55 Min None 90 Min None 3 Hrs None<br />

2 Hrs None 3 Hrs None 4 Hrs None 7 Hrs None 12 Hrs None 26 Hrs None<br />

3 Hrs None 4 Hrs None 5 Hrs None 10 Hrs None 16 Hrs None 35 Hrs None<br />

Hempel's PreSale System 2.6.16 (Build 673)<br />

User name:<br />

Henrik Berg<br />

Quality Code: 34-11 / 0710<br />

Printed at: 21.07.2010 11:35 Department name: Sales Denmark Environment : Medium<br />

Created/Last modified: 21.07.2010 11:29 DKHEJ0181 Page: 19<br />

<strong>HEMPEL</strong>

Area:<br />

AFT DECK<br />

Remarks:<br />

Specification sheet<br />

Hempel (Denmark) A/S<br />

Project:<br />

DANA - DOKNING 2010<br />

Obj. ref.: 7912680<br />

Area size:<br />

300 sqm<br />

The surface must be completely clean and dry with a temperature 3°C/5°F above the dew point to avoid condensation.<br />

If a full blasting is desired, note that the primer coats are to be applied as full coats.<br />

The specified high film thickness can best be obtained by airless spray application. If another application method is used more applications are necessary to achieve the specified dry<br />

film thickness.<br />

Pit-corroded areas may call for an extra coat to fill out pittings.<br />

If the maximum recoating interval is exceeded, roughening of the surface is necessary to ensure intercoat adhesion.<br />

Before recoating after exposure in contaminated environments, clean the surface thoroughly by (high pressure) fresh water hosing and allow to dry.<br />

Product information:<br />

Mixing ratio Pot life Dry to touch Flash<br />

Application restrictions<br />

Shade no.<br />

Volume<br />

solids %<br />

Curing<br />

agent<br />

volume<br />

20°C 20°C<br />

point<br />

°C<br />

VOC<br />

g/ltr MAL Thinner<br />

Min. Temp. Max. RH%<br />

°C<br />

<strong>HEMPEL</strong>'S ZINC PRIMER 16490 19840 33 30 min 7 590 08450 4-3<br />

HEMPATEX HI-BUILD 46410 50630 42 4 h 24 513 08080 4-5<br />

HEMPATEX HI-BUILD 46410 40640 43 4 h 24 507 08080 4-5<br />

HEMPATEX ENAMEL 56360 40640 30 3 h 25 607 08080 4-3<br />

The data, specifications, directions and recommendations (hereinafter "Information") given in this painting specification are based upon test results obtained under controlled or specifically defined conditions and said Information is correct to the<br />

best of our knowledge. The User must satisfy itself that it is appropriate to use the Product in accordance with the Information in the actual conditions under which the Product is intended to be used, and the Manufacturer and Seller do not<br />

guarantee the accuracy, completeness or appropriateness of the Information when the Product is used in those conditions. The provisions of Clause 8 of the GENERAL CONDITIONS OF SALE, DELIVERY AND SERVICE shall apply to any and<br />

all claims arising out of or in connection with the use of the Product as recommended above, overleaf or otherwise.<br />

Hempel's PreSale System 2.6.16 (Build 673)<br />

User name:<br />

Henrik Berg<br />

Quality Code: 34-11 / 0710<br />

<strong>HEMPEL</strong><br />

Printed at: 21.07.2010 11:35 Department name: Sales Denmark Environment : Medium<br />

Created/Last modified: 21.07.2010 11:29 DKHEJ0181 Page: 20

Specification sheet<br />

Hempel (Denmark) A/S<br />

Project:<br />

Area:<br />

CRANE FOUNDATIONS, GANTRY ETC.<br />

Surface preparation:<br />

DANA - DOKNING 2010<br />

Oil and grease etc. to be removed by emulsion cleaning. Entire area to be (high pressure)<br />

fresh water cleaned in order to remove salts and other contaminants. When the surface is<br />

dry: Abrasive blasting to minimum Sa 2½ according to ISO 8501-1:2007 with a surface<br />

profile corresponding to Rugotest No. 3 BN 9a.<br />

Product name (including quality number)<br />

Treated area<br />

% Shade<br />

Shade no.<br />

Obj. ref.: 7912680<br />

Area size:<br />

150 sqm<br />

Film thickness Theoretical spreading Application methods<br />

(micron)<br />

rate<br />

Roller<br />

Wet Dry (sqm/ltr) Brush<br />

Spray<br />

Recommended<br />

<strong>HEMPEL</strong>'S ZINC PRIMER 16490 20 Metal grey 19840 100 35 9.4 (X) X .019"-.021" 200 bar<br />

HEMPATEX HI-BUILD 46410 20 Red 50630 250 100 4.2 (X) (X) X .017"-.021" 175 bar<br />

HEMPATEX HI-BUILD 46410 20 Grey 12170 250 100 4.2 (X) (X) X .017"-.021" 175 bar<br />

HEMPATEX ENAMEL 56360 f/c Grey 12170 100 35 9.1 (X) (X) X .017" 150 bar<br />

t/u: touch up f/c: full coat Total d.f.t. 270 X: Recommended (X): Possible<br />

Recoating intervals. Ample ventilation Hrs=Hour(s) Mth=Month(s) N/R=Not Recommended<br />

Quality no<br />

16490<br />

46410<br />

46410<br />

D.F.T.<br />

(micron)<br />

35<br />

100<br />

100<br />

Remarks and Product information see next page.<br />

Recoated with<br />

quality no<br />

46410<br />

46410<br />

56360<br />

Nozzle<br />

orifice<br />

40°C 30°C 20°C 10°C 0°C -10°C<br />

Nozzle<br />

pressure<br />

Min. Max. Min. Max. Min. Max. Min. Max. Min. Max. Min. Max.<br />

15 Min None 25 Min None 30 Min None 55 Min None 90 Min None 3 Hrs None<br />

2 Hrs None 3 Hrs None 4 Hrs None 7 Hrs None 12 Hrs None 26 Hrs None<br />

3 Hrs None 4 Hrs None 5 Hrs None 10 Hrs None 16 Hrs None 35 Hrs None<br />

Hempel's PreSale System 2.6.16 (Build 673)<br />

User name:<br />

Henrik Berg<br />

Quality Code: 34-11 / 0710<br />

Printed at: 21.07.2010 11:35 Department name: Sales Denmark Environment : Medium<br />

Created/Last modified: 21.07.2010 11:29 DKHEJ0181 Page: 21<br />

<strong>HEMPEL</strong>

Specification sheet<br />

Hempel (Denmark) A/S<br />

Project:<br />

Area:<br />

CRANE FOUNDATIONS, GANTRY ETC.<br />

Remarks:<br />

DANA - DOKNING 2010<br />

Obj. ref.: 7912680<br />

Area size:<br />

150 sqm<br />

Normal good painting practice must be followed throughout the entire painting procedure.<br />

The surface must be completely clean and dry with a temperature 3°C/5°F above the dew point to avoid condensation.<br />

If a full blasting is desired, note that the primer coats are to be applied as full coats.<br />

The specified high film thickness can best be obtained by airless spray application. If another application method is used more applications are necessary to achieve the specified dry<br />

film thickness.<br />

Pit-corroded areas may call for an extra coat to fill out pittings.<br />

Before recoating after exposure in contaminated environments, clean the surface thoroughly by (high pressure) fresh water hosing and allow to dry.<br />

Product information:<br />

Mixing ratio Pot life Dry to touch Flash<br />

Application restrictions<br />

Shade no.<br />

Volume<br />

solids %<br />

Curing<br />

agent<br />

volume<br />

20°C 20°C<br />

point<br />

°C<br />

VOC<br />

g/ltr MAL Thinner<br />

Min. Temp. Max. RH%<br />

°C<br />

<strong>HEMPEL</strong>'S ZINC PRIMER 16490 19840 33 30 min 7 590 08450 4-3<br />

HEMPATEX HI-BUILD 46410 50630 42 4 h 24 513 08080 4-5<br />

HEMPATEX HI-BUILD 46410 12170 42 4 h 24 510 08080 4-5<br />

HEMPATEX ENAMEL 56360 12170 32 3 h 25 601 08080 4-3<br />

The data, specifications, directions and recommendations (hereinafter "Information") given in this painting specification are based upon test results obtained under controlled or specifically defined conditions and said Information is correct to the<br />

best of our knowledge. The User must satisfy itself that it is appropriate to use the Product in accordance with the Information in the actual conditions under which the Product is intended to be used, and the Manufacturer and Seller do not<br />

guarantee the accuracy, completeness or appropriateness of the Information when the Product is used in those conditions. The provisions of Clause 8 of the GENERAL CONDITIONS OF SALE, DELIVERY AND SERVICE shall apply to any and<br />

all claims arising out of or in connection with the use of the Product as recommended above, overleaf or otherwise.<br />

Hempel's PreSale System 2.6.16 (Build 673)<br />

User name:<br />

Henrik Berg<br />

Quality Code: 34-11 / 0710<br />

<strong>HEMPEL</strong><br />

Printed at: 21.07.2010 11:35 Department name: Sales Denmark Environment : Medium<br />

Created/Last modified: 21.07.2010 11:29 DKHEJ0181 Page: 22

Area:<br />

HULL MARKING<br />

Surface preparation:<br />

Specification sheet<br />

Hempel (Denmark) A/S<br />

Project:<br />

IMPORTANT NOTICE: AREA TO BE TREATED AND PAINTED AS SURROUNDING<br />

AREAS, WITH ADDITIONAL TOPCOAT 55210-10000<br />

Product name (including quality number)<br />

DANA - DOKNING 2010 Obj. ref.: 7912680<br />

Treated area<br />

% Shade<br />

Shade no.<br />

Film thickness Theoretical spreading Application methods<br />

(micron)<br />

rate<br />

Roller<br />

Wet Dry (sqm/ltr) Brush<br />

Spray<br />

Recommended<br />

HEMPADUR QUATTRO 17634 t/u Red 50630 175 125 5.8 (X) (X) X .021"-.025" 250 bar<br />

HEMPADUR QUATTRO 17634 t/u Yellow 22090 175 125 5.8 (X) (X) X .021"-.025" 250 bar<br />

HEMPATHANE TOPCOAT 55210 f/c To shade 99990 100 50 10.0 (X) (X) X .017"-.019" 150 bar<br />

HEMPATHANE TOPCOAT 55210 f/c White 10000 100 50 9.8 (X) (X) X .017"-.019" 150 bar<br />

t/u: touch up f/c: full coat Total d.f.t. 350 X: Recommended (X): Possible<br />

Recoating intervals. Ample ventilation Hrs=Hour(s) Mth=Month(s) N/R=Not Recommended<br />

Quality no<br />

17634<br />

17634<br />

55210<br />

D.F.T.<br />

(micron)<br />

125<br />

125<br />

50<br />

Remarks and Product information see next page.<br />

Recoated with<br />

quality no<br />

17634<br />

55210<br />

55210<br />

Nozzle<br />

orifice<br />

40°C 30°C 20°C 10°C 0°C -10°C<br />

Nozzle<br />

pressure<br />

Min. Max. Min. Max. Min. Max. Min. Max. Min. Max. Min. Max.<br />

Hempel's PreSale System 2.6.16 (Build 673)<br />

User name:<br />

Henrik Berg<br />

Quality Code: 34-11 / 0710<br />

Printed at: 21.07.2010 11:35 Department name: Sales Denmark Environment : Medium<br />

Created/Last modified: 21.07.2010 11:29 DKHEJ0181 Page: 23<br />

1 Hrs None 90 Min None 2 Hrs None 4 Hrs None 9 Hrs None 18 Hrs None<br />

1 Hrs 10 Day 90 Min 15 Day 2 Hrs 20 Day 4 Hrs 40 Day 9 Hrs 90 Day 18 Hrs 90 Day<br />

5 Hrs None 8 Hrs None 10 Hrs None 20 Hrs None 45 Hrs None 3½ Day None<br />

<strong>HEMPEL</strong>

Area:<br />

HULL MARKING<br />

Remarks:<br />

Specification sheet<br />

Hempel (Denmark) A/S<br />

Project:<br />

DANA - DOKNING 2010 Obj. ref.: 7912680<br />

The surface must be completely clean and dry with a temperature 3°C/5°F above the dew point to avoid condensation.<br />

If the working procedure calls for a blast primer then use a thinned version of HEMPADUR QUATTRO in 40 - 50 microns dft.<br />

The specified high film thickness can best be obtained by airless spray application. If another application method is used more applications are necessary to achieve the specified dry<br />

film thickness.<br />

Pit-corroded areas may call for an extra coat to fill out pittings.<br />

Consult the separate APPLICATION INSTRUCTIONS for HEMPADUR QUATTRO 17634.<br />

If the maximum recoating interval is exceeded, roughening of the surface is necessary to ensure intercoat adhesion.<br />

Before recoating after exposure in contaminated environments, clean the surface thoroughly by (high pressure) fresh water hosing and allow to dry.<br />

Curing agent 97334 is hazy. This is intended and has no influence on the performance.<br />

Product information:<br />

Mixing ratio Pot life Dry to touch Flash<br />

Application restrictions<br />

Shade no.<br />

Volume<br />

solids %<br />

Curing<br />

agent<br />

volume<br />

20°C 20°C<br />

point<br />

°C<br />

VOC<br />

g/ltr MAL Thinner<br />

Min. Temp. Max. RH%<br />

°C<br />

HEMPADUR QUATTRO 17634 50630 72 97334 4 : 1 2 h 4 h 27 275 4-5 08450 -10<br />

HEMPADUR QUATTRO 17634 22090 72 97334 4 : 1 2 h 4 h 27 270 4-5 08450 -10<br />

HEMPATHANE TOPCOAT 55210 99990 50 95370 7 : 1 4 h 8 h 33 450 08080 -10<br />

HEMPATHANE TOPCOAT 55210 10000 49 95370 7 : 1 4 h 8 h 33 445 4-3 08080 -10<br />

The data, specifications, directions and recommendations (hereinafter "Information") given in this painting specification are based upon test results obtained under controlled or specifically defined conditions and said Information is correct to the<br />

best of our knowledge. The User must satisfy itself that it is appropriate to use the Product in accordance with the Information in the actual conditions under which the Product is intended to be used, and the Manufacturer and Seller do not<br />

guarantee the accuracy, completeness or appropriateness of the Information when the Product is used in those conditions. The provisions of Clause 8 of the GENERAL CONDITIONS OF SALE, DELIVERY AND SERVICE shall apply to any and<br />

all claims arising out of or in connection with the use of the Product as recommended above, overleaf or otherwise.<br />

Hempel's PreSale System 2.6.16 (Build 673)<br />

User name:<br />

Henrik Berg<br />

Quality Code: 34-11 / 0710<br />

<strong>HEMPEL</strong><br />

Printed at: 21.07.2010 11:35 Department name: Sales Denmark Environment : Medium<br />

Created/Last modified: 21.07.2010 11:29 DKHEJ0181 Page: 24

Area:<br />

CAP<br />

Surface preparation:<br />

Specification sheet<br />

Hempel (Denmark) A/S<br />

Project:<br />

DANA - DOKNING 2010 Obj. ref.: 7912680<br />

Oil and grease etc. to be removed by emulsion cleaning. Entire area to be (high pressure)<br />

fresh water cleaned in order to remove salts and other contaminants. When the surface is<br />

dry: Abrasive blasting to minimum Sa 2½ according to ISO 8501-1:2007 with a surface<br />

profile corresponding to Rugotest No. 3 BN 9a.<br />

Product name (including quality number)<br />

Treated area<br />

% Shade<br />

Shade no.<br />

Film thickness Theoretical spreading Application methods<br />

(micron)<br />

rate<br />

Roller<br />

Wet Dry (sqm/ltr) Brush<br />

Spray<br />

Recommended<br />

<strong>HEMPEL</strong>'S ZINC PRIMER 16490 60 Metal grey 19840 100 35 9.4 (X) X .019"-.021" 200 bar<br />

HEMPATEX HI-BUILD 46410 60 Red 50630 250 100 4.2 (X) (X) X .017"-.021" 175 bar<br />

HEMPATEX HI-BUILD 46410 60 White 10000 225 100 4.3 (X) (X) X .017"-.021" 175 bar<br />

<strong>HEMPEL</strong>'S HI-VEE 56540 f/c Orange 50180 100 40 11.0 (X) X .015"-.018" 150 bar<br />

<strong>HEMPEL</strong>'S HI-VEE 56540 f/c Orange 50180 100 40 11.0 (X) X .015"-.018" 150 bar<br />

<strong>HEMPEL</strong>'S HI-VEE LACQUER 06520 f/c Transparent 00000 100 25 10.8<br />

0.0 bar<br />

<strong>HEMPEL</strong>'S HI-VEE LACQUER 06520 f/c Transparent 00000 100 25 10.8<br />

0.0 bar<br />

t/u: touch up f/c: full coat Total d.f.t. 365 X: Recommended (X): Possible<br />

Recoating intervals. Ample ventilation Hrs=Hour(s) Mth=Month(s) N/R=Not Recommended<br />

Quality no<br />

16490<br />

46410<br />

46410<br />

56540<br />

56540<br />

06520<br />

D.F.T.<br />

(micron)<br />

35<br />

100<br />

100<br />

40<br />

40<br />

25<br />

Remarks and Product information see next page.<br />

Recoated with<br />

quality no<br />

46410<br />

46410<br />

56540<br />

56540<br />

06520<br />

06520<br />

Nozzle<br />

orifice<br />

40°C 30°C 20°C 10°C 0°C -10°C<br />

Nozzle<br />

pressure<br />

Min. Max. Min. Max. Min. Max. Min. Max. Min. Max. Min. Max.<br />

15 Min None 25 Min None 30 Min None 55 Min None 90 Min None 3 Hrs None<br />

2 Hrs None 3 Hrs None 4 Hrs None 7 Hrs None 12 Hrs None 26 Hrs None<br />

3 Hrs None 4 Hrs None 5 Hrs None 10 Hrs None 16 Hrs None 35 Hrs None<br />

1 Hrs None 90 Min None 2 Hrs None 4 Hrs None 6 Hrs None 13 Hrs None<br />

1 Hrs None 90 Min None 2 Hrs None 4 Hrs None 6 Hrs None 13 Hrs None<br />

Error Error Error Error Error Error Error Error Error Error Error Error<br />

Hempel's PreSale System 2.6.16 (Build 673)<br />

User name:<br />

Henrik Berg<br />

Quality Code: 34-11 / 0710<br />

Printed at: 21.07.2010 11:35 Department name: Sales Denmark Environment : Medium<br />

Created/Last modified: 21.07.2010 11:29 DKHEJ0181 Page: 25<br />

<strong>HEMPEL</strong>

Area:<br />

CAP<br />

Remarks:<br />

Specification sheet<br />

Hempel (Denmark) A/S<br />

Project:<br />

DANA - DOKNING 2010 Obj. ref.: 7912680<br />

The surface must be completely clean and dry with a temperature 3°C/5°F above the dew point to avoid condensation.<br />

If a full blasting is desired, note that the primer coats are to be applied as full coats.<br />

The specified high film thickness can best be obtained by airless spray application. If another application method is used more applications are necessary to achieve the specified dry<br />

film thickness.<br />

Pit-corroded areas may call for an extra coat to fill out pittings.<br />

To obtain full opacity, an extra coat of the topcoat may be necessary.<br />

Product information:<br />

Mixing ratio Pot life Dry to touch Flash<br />

Application restrictions<br />

Shade no.<br />

Volume<br />

solids %<br />

Curing<br />

agent<br />

volume<br />

20°C 20°C<br />

point<br />

°C<br />

VOC<br />

g/ltr MAL Thinner<br />

Min. Temp. Max. RH%<br />

°C<br />

<strong>HEMPEL</strong>'S ZINC PRIMER 16490 19840 33 30 min 7 590 08450 4-3<br />

HEMPATEX HI-BUILD 46410 50630 42 4 h 24 513 08080 4-5<br />

HEMPATEX HI-BUILD 46410 10000 43 4 h 24 507 08080 4-5<br />

<strong>HEMPEL</strong>'S HI-VEE 56540 50180 44 1 h 38 448 08230 2-1<br />

<strong>HEMPEL</strong>'S HI-VEE 56540 50180 44 1 h 38 448 08230 2-1<br />

<strong>HEMPEL</strong>'S HI-VEE LACQUER 06520 00000 27 32 582 08230 3-3<br />

<strong>HEMPEL</strong>'S HI-VEE LACQUER 06520 00000 27 32 582 08230 3-3<br />

The data, specifications, directions and recommendations (hereinafter "Information") given in this painting specification are based upon test results obtained under controlled or specifically defined conditions and said Information is correct to the<br />

best of our knowledge. The User must satisfy itself that it is appropriate to use the Product in accordance with the Information in the actual conditions under which the Product is intended to be used, and the Manufacturer and Seller do not<br />

guarantee the accuracy, completeness or appropriateness of the Information when the Product is used in those conditions. The provisions of Clause 8 of the GENERAL CONDITIONS OF SALE, DELIVERY AND SERVICE shall apply to any and<br />

all claims arising out of or in connection with the use of the Product as recommended above, overleaf or otherwise.<br />

Hempel's PreSale System 2.6.16 (Build 673)<br />

User name:<br />

Henrik Berg<br />

Quality Code: 34-11 / 0710<br />

<strong>HEMPEL</strong><br />

Printed at: 21.07.2010 11:35 Department name: Sales Denmark Environment : Medium<br />

Created/Last modified: 21.07.2010 11:29 DKHEJ0181 Page: 26