kinetic response of thermosetting adhesive systems to heat

kinetic response of thermosetting adhesive systems to heat

kinetic response of thermosetting adhesive systems to heat

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Temperature effects on internal mat characteristics during testing<br />

In order <strong>to</strong> resolve the role <strong>of</strong> the <strong>adhesive</strong> in affecting the shear strength <strong>of</strong> compressed<br />

fiber samples, a number <strong>of</strong> fiber samples were compressed in the absence <strong>of</strong> <strong>adhesive</strong>, and the<br />

results compared with corresponding samples pressed with <strong>adhesive</strong>. Clearly, the interplay <strong>of</strong><br />

mechanisms which influence the structure and properties <strong>of</strong> compressed fiber networks is highly<br />

complex; it is beyond the scope <strong>of</strong> the present discussion and will be the subject <strong>of</strong> future<br />

publications. Such mechanisms are, however, assuredly influenced by fiber type and<br />

juxtaposition, transient moisture and temperature conditions, and the magnitude and duration <strong>of</strong><br />

applied compressive stress.<br />

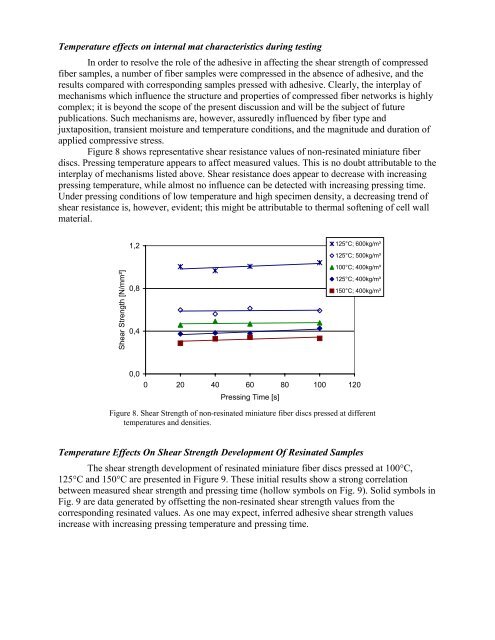

Figure 8 shows representative shear resistance values <strong>of</strong> non-resinated miniature fiber<br />

discs. Pressing temperature appears <strong>to</strong> affect measured values. This is no doubt attributable <strong>to</strong> the<br />

interplay <strong>of</strong> mechanisms listed above. Shear resistance does appear <strong>to</strong> decrease with increasing<br />

pressing temperature, while almost no influence can be detected with increasing pressing time.<br />

Under pressing conditions <strong>of</strong> low temperature and high specimen density, a decreasing trend <strong>of</strong><br />

shear resistance is, however, evident; this might be attributable <strong>to</strong> thermal s<strong>of</strong>tening <strong>of</strong> cell wall<br />

material.<br />

Shear Strength [N/mm²]<br />

1,2<br />

0,8<br />

0,4<br />

0,0<br />

125°C; 600kg/m³<br />

125°C; 500kg/m³<br />

100°C; 400kg/m³<br />

125°C; 400kg/m³<br />

150°C; 400kg/m³<br />

0 20 40 60<br />

Pressing Time [s]<br />

80 100 120<br />

Figure 8. Shear Strength <strong>of</strong> non-resinated miniature fiber discs pressed at different<br />

temperatures and densities.<br />

Temperature Effects On Shear Strength Development Of Resinated Samples<br />

The shear strength development <strong>of</strong> resinated miniature fiber discs pressed at 100°C,<br />

125°C and 150°C are presented in Figure 9. These initial results show a strong correlation<br />

between measured shear strength and pressing time (hollow symbols on Fig. 9). Solid symbols in<br />

Fig. 9 are data generated by <strong>of</strong>fsetting the non-resinated shear strength values from the<br />

corresponding resinated values. As one may expect, inferred <strong>adhesive</strong> shear strength values<br />

increase with increasing pressing temperature and pressing time.