You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

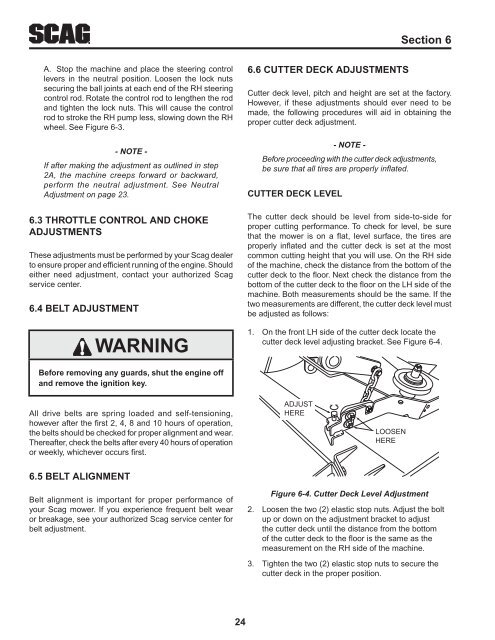

R Section6A. Stop the machine and place the steering controllevers in the neutral position. Loosen the lock nutssecuring the ball joints at each end of the RH steeringcontrol rod. Rotate the control rod to lengthen the rodand tighten the lock nuts. This will cause the controlrod to stroke the RH pump less, slowing down the RHwheel. See Figure 6-3.- NOTE -If after making the adjustment as outlined in step2A, the machine creeps forward or backward,perform the neutral adjustment. See NeutralAdjustment on page 23.6.3 Throttle Control and ChokeAdjustmentsThese adjustments must be performed by your <strong>Scag</strong> dealerto ensure proper and efficient running of the engine. Shouldeither need adjustment, contact your authorized <strong>Scag</strong>service center.6.4 BELT ADJUSTMENT6.6 CUTTER DECK ADJUSTMENTSCutter deck level, pitch and height are set at the factory.However, if these adjustments should ever need to bemade, the following procedures will aid in obtaining theproper cutter deck adjustment.- NOTE -Before proceeding with the cutter deck adjustments,be sure that all tires are properly inflated.Cutter Deck LevelThe cutter deck should be level from side-to-side forproper cutting performance. To check for level, be surethat the mower is on a flat, level surface, the tires areproperly inflated and the cutter deck is set at the mostcommon cutting height that you will use. On the RH sideof the machine, check the distance from the bottom of thecutter deck to the floor. Next check the distance from thebottom of the cutter deck to the floor on the LH side of themachine. Both measurements should be the same. If thetwo measurements are different, the cutter deck level mustbe adjusted as follows:WARNINGBefore removing any guards, shut the engine offand remove the ignition key.1.On the front LH side of the cutter deck locate thecutter deck level adjusting bracket. See Figure 6-4.All drive belts are spring loaded and self-tensioning,however after the first 2, 4, 8 and 10 hours of operation,the belts should be checked for proper alignment and wear.Thereafter, check the belts after every 40 hours of operationor weekly, whichever occurs first.ADJUSTHERELOOSENHERE6.5 BELT ALIGNMENTBelt alignment is important for proper performance ofyour <strong>Scag</strong> mower. If you experience frequent belt wearor breakage, see your authorized <strong>Scag</strong> service center forbelt adjustment.2.3.Figure 6-4. Cutter Deck Level AdjustmentLoosen the two (2) elastic stop nuts. Adjust the boltup or down on the adjustment bracket to adjustthe cutter deck until the distance from the bottomof the cutter deck to the floor is the same as themeasurement on the RH side of the machine.Tighten the two (2) elastic stop nuts to secure thecutter deck in the proper position.24