Strength of structures and components.pdf - FESB

Strength of structures and components.pdf - FESB

Strength of structures and components.pdf - FESB

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

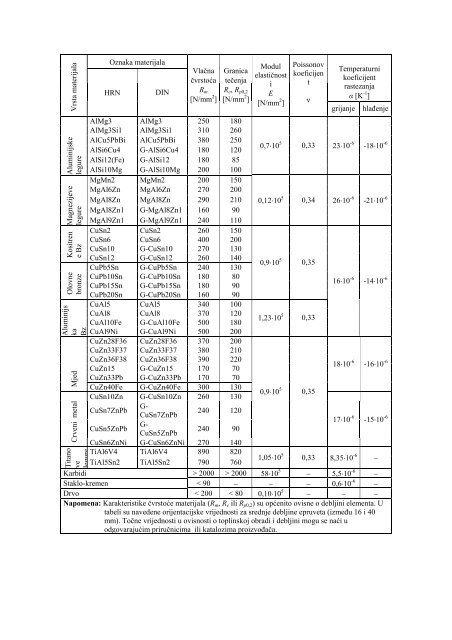

Vrsta materijala<br />

Aluminijske<br />

legure<br />

Magnezijeve<br />

legure<br />

Kositren<br />

e Bz<br />

Olovne<br />

bronze<br />

Aluminijs<br />

ka<br />

Bz<br />

Mjed<br />

Crveni metal<br />

Titano<br />

ve<br />

legure<br />

Oznaka materijala<br />

HRN<br />

DIN<br />

Vlačna<br />

čvrstoća<br />

R m<br />

[N/mm 2 ]<br />

Granica<br />

tečenja<br />

R e , R p0,2<br />

[N/mm 2 ]<br />

AlMg3 AlMg3 250 180<br />

AlMg3Si1 AlMg3Si1 310 260<br />

AlCu5PbBi AlCu5PbBi 380 250<br />

AlSi6Cu4 G-AlSi6Cu4 180 120<br />

AlSi12(Fe) G-AlSi12 180 85<br />

AlSi10Mg G-AlSi10Mg 200 100<br />

MgMn2 MgMn2 200 150<br />

MgAl6Zn MgAl6Zn 270 200<br />

MgAl8Zn MgAl8Zn 290 210<br />

MgAl8Zn1 G-MgAl8Zn1 160 90<br />

MgAl9Zn1 G-MgAl9Zn1 240 110<br />

CuSn2 CuSn2 260 150<br />

CuSn6 CuSn6 400 200<br />

CuSn10 G-CuSn10 270 130<br />

CuSn12 G-CuSn12 260 140<br />

CuPb5Sn G-CuPb5Sn 240 130<br />

CuPb10Sn G-CuPb10Sn 180 80<br />

CuPb15Sn G-CuPb15Sn 180 90<br />

CuPb20Sn G-CuPb20Sn 160 90<br />

CuAl5 CuAl5 340 100<br />

CuAl8 CuAl8 370 120<br />

CuAl10Fe G-CuAl10Fe 500 180<br />

CuAl9Ni G-CuAl9Ni 500 200<br />

CuZn28F36 CuZn28F36 370 200<br />

CuZn33F37 CuZn33F37 380 210<br />

CuZn36F38 CuZn36F38 390 220<br />

CuZn15 G-CuZn15 170 70<br />

CuZn33Pb G-CuZn33Pb 170 70<br />

CuZn40Fe G-CuZn40Fe 300 130<br />

CuSn10Zn G-CuSn10Zn 260 130<br />

CuSn7ZnPb<br />

G-<br />

CuSn7ZnPb<br />

240 120<br />

CuSn5ZnPb<br />

G-<br />

CuSn5ZnPb<br />

240 90<br />

CuSn6ZnNi G-CuSn6ZnNi 270 140<br />

TiAl6V4 TiAl6V4 890 820<br />

TiAl5Sn2 TiAl5Sn2 790 760<br />

Modul<br />

elastičnost<br />

i<br />

E<br />

[N/mm 2 ]<br />

Poissonov<br />

koeficijen<br />

t<br />

ν<br />

Temperaturni<br />

koeficijent<br />

rastezanja<br />

α [K -1 ]<br />

grijanje hlađenje<br />

0,7⋅10 5 0,33 23⋅10 -6 -18⋅10 -6<br />

0,12⋅10 5 0,34 26⋅10 -6 -21⋅10 -6<br />

0,9⋅10 5 0,35<br />

1,23⋅10 5 0,33<br />

0,9⋅10 5 0,35<br />

16⋅10 -6 -14⋅10 -6<br />

18⋅10 -6 -16⋅10 -6<br />

17⋅10 -6 -15⋅10 -6<br />

1,05⋅10 5 0,33 8,35⋅10 -6 −<br />

Karbidi > 2000 > 2000 58⋅10 5 − 5,5⋅10 -6 −<br />

Staklo-kremen < 90 − − − 0,6⋅10 -6 −<br />

Drvo < 200 < 80 0,10⋅10 5 − − −<br />

Napomena: Karakteristike čvrstoće materijala (R m , R e ili R p0,2 ) su općenito ovisne o debljini elementa. U<br />

tabeli su navedene orijentacijske vrijednosti za srednje debljine epruveta (između 16 i 40<br />

mm). Točne vrijednosti u ovisnosti o toplinskoj obradi i debljini mogu se naći u<br />

odgovarajućim priručnicima ili katalozima proizvođača.