Gesundheit Healthcare - M2M Alliance

Gesundheit Healthcare - M2M Alliance

Gesundheit Healthcare - M2M Alliance

Erfolgreiche ePaper selbst erstellen

Machen Sie aus Ihren PDF Publikationen ein blätterbares Flipbook mit unserer einzigartigen Google optimierten e-Paper Software.

Anwendungen und Referenzen Applications and References<br />

Aufwände auf Seite des Anwenders entfallen.<br />

Die Abrechnung erfolgt monatlich<br />

als Providing-Gebühr, wodurch die Unterhaltungskosten<br />

gering und kalkulierbar<br />

bleiben.<br />

Ausgelegt ist dieses Web-Portal, das Ende<br />

des 1. Quartals 2010 auf dem Markt verfügbar<br />

sein wird, für alle, die den Betrieb kleiner<br />

dezentraler Anlagen oder Maschinen<br />

wirtschaftlich überwachen möchten.<br />

The costs for purchasing and operating<br />

equipment are significantly reduced by<br />

using a web portal. The use of security<br />

standards can continue to protect communication<br />

from unauthorized access.<br />

The proposed project is an example of the<br />

trend towards "remote control via Internet"<br />

with respect to web-based process monitoring<br />

and control in water management.<br />

Innovative communication<br />

With the introduction of the new HydroDat<br />

V8 process control system for urban drainage<br />

in Frankfurt am Main, all 67 existing<br />

special structures that had been linked via<br />

analog dial-up lines to the central control<br />

station were changed to modern GPRS<br />

transmission with Internet technology.<br />

Powerful embedded control<br />

The transformation of the process signals<br />

into the TCP/IP protocol incorporate HST<br />

Telematic SMART-200 embedded controllers<br />

which combine the PLC and industrial<br />

PC technology in one device. Unlike other<br />

approaches, where the TCP/IP protocol is<br />

already being changed by an intelligent<br />

22 <strong>M2M</strong> Journal 04 | 06/10<br />

modem into a serial protocol, it stays<br />

available in the TeleMatic-System and<br />

transparent all the way to the controls.<br />

It has been proven to be an advantage that<br />

the online and archive data is processed<br />

separately in the software. This way, all<br />

measurement data which is to be archived<br />

can be directly saved onto the substation<br />

for up to 6 months after the delta-event procedure<br />

and upon connection can automatically<br />

be sent to the process control system.<br />

The extensive and freely configurable archiving<br />

procedure needs no compression,<br />

is therefore loss-free and forms the basis<br />

for an optimal analysis of the process.<br />

High investment security<br />

The openness of the system is secured in<br />

such that the coupled embedded controls<br />

exchange their data by way of the OPC with<br />

the process control system. This interface<br />

allows other processes to be integrated<br />

into the process control system or the process<br />

data of the HST stations to be transferred<br />

into another visualization system.<br />

Conventional remote control technology in<br />

the field of wastewater is being increasingly<br />

replaced through the meshing of local<br />

networks with web technology. Since the<br />

basic communication structure remains<br />

the same when there are changes such as<br />

the transmission path, a safe and sure investment<br />

for the future is assured.<br />

Secure communications<br />

All TeleMatics stations connected with<br />

GPRS communicate virtually in real time<br />

from a VPN connection furnished by a<br />

GPRS provider and are encrypted with the<br />

process control system at the control center,<br />

which is equipped with a VPN router.<br />

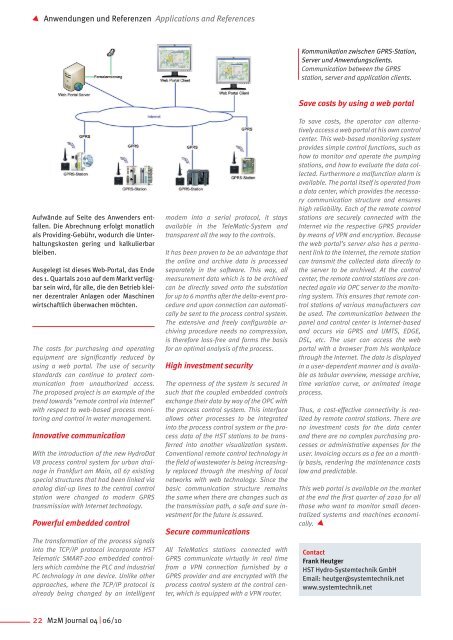

Kommunikation zwischen GPRS-Station,<br />

Server und Anwendungsclients.<br />

Communication between the GPRS<br />

station, server and application clients.<br />

Save costs by using a web portal<br />

To save costs, the operator can alternatively<br />

access a web portal at his own control<br />

center. This web-based monitoring system<br />

provides simple control functions, such as<br />

how to monitor and operate the pumping<br />

stations, and how to evaluate the data collected.<br />

Furthermore a malfunction alarm is<br />

available. The portal itself is operated from<br />

a data center, which provides the necessary<br />

communication structure and ensures<br />

high reliability. Each of the remote control<br />

stations are securely connected with the<br />

Internet via the respective GPRS provider<br />

by means of VPN and encryption. Because<br />

the web portal’s server also has a permanent<br />

link to the Internet, the remote station<br />

can transmit the collected data directly to<br />

the server to be archived. At the control<br />

center, the remote control stations are connected<br />

again via OPC server to the monitoring<br />

system. This ensures that remote control<br />

stations of various manufacturers can<br />

be used. The communication between the<br />

panel and control center is Internet-based<br />

and occurs via GPRS and UMTS, EDGE,<br />

DSL, etc. The user can access the web<br />

portal with a browser from his workplace<br />

through the Internet. The data is displayed<br />

in a user-dependent manner and is available<br />

as tabular overview, message archive,<br />

time variation curve, or animated image<br />

process.<br />

Thus, a cost-effective connectivity is realized<br />

by remote control stations. There are<br />

no investment costs for the data center<br />

and there are no complex purchasing processes<br />

or administrative expenses for the<br />

user. Invoicing occurs as a fee on a monthly<br />

basis, rendering the maintenance costs<br />

low and predictable.<br />

This web portal is available on the market<br />

at the end the first quarter of 2010 for all<br />

those who want to monitor small decentralized<br />

systems and machines economically.<br />

Contact<br />

Frank Heutger<br />

HST Hydro-Systemtechnik GmbH<br />

Email: heutger@systemtechnik.net<br />

www.systemtechnik.net