Tensior T8 - Eijkelkamp Agrisearch Equipment

Tensior T8 - Eijkelkamp Agrisearch Equipment

Tensior T8 - Eijkelkamp Agrisearch Equipment

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

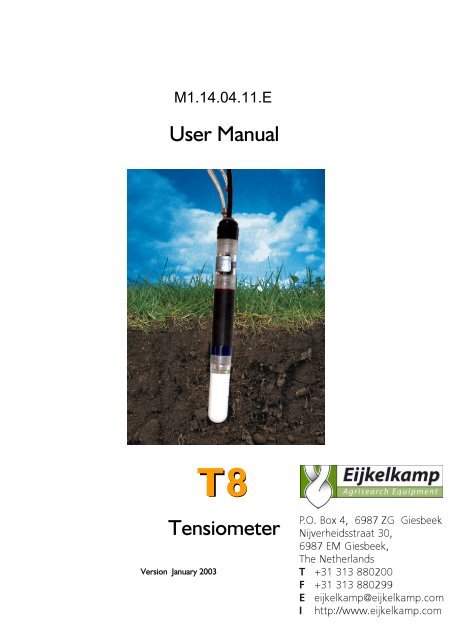

User Manual<br />

<strong>T8</strong><br />

Tensiometer<br />

Version January 2003<br />

<strong>T8</strong><br />

P.O. Box 4, 6987 ZG Giesbeek<br />

Nijverheidsstraat 30,<br />

6987 EM Giesbeek,<br />

The Netherlands<br />

T +31 313 880200<br />

F +31 313 880299<br />

E eijkelkamp@eijkelkamp.com<br />

I http://www.eijkelkamp.com

Foreword<br />

The success of any technical system is directly depending on a correct<br />

operation. Moreover, the systems must be reliable, durable and require a<br />

minimum of maintenance to achieve target-directed results and keep the<br />

servicing low.<br />

At the beginning of a measuring task or research project the target, all effective<br />

values and the surrounding conditions must be defined. This leads to the<br />

demands for the scientific and technical project management which describes<br />

all quality related processes and decides on the used methods, the technical<br />

and measurement tools, the verification of the results and the modelling.<br />

The continuously optimised and synergic correlation of all segments and it's<br />

quality assurance are finally decisive for the success of a project.<br />

Thus, I would be pleased to receive your critiques and appraisals.<br />

München, 30.09.2002<br />

3

Table of contents<br />

1 Content of delivery ....................................................................................7<br />

2 Short instructions .......................................................................................7<br />

3 Safety notes................................................................................................9<br />

4 Description of the <strong>T8</strong>...............................................................................10<br />

4<br />

4.1 Output signals.....................................................................................10<br />

4.2 Sensor body........................................................................................10<br />

4.2.1 Pressure sensor.........................................................................10<br />

4.2.2 Temperature sensor .................................................................11<br />

4.2.3 IR indicator................................................................................11<br />

4.3 The ceramic cup .................................................................................12<br />

5 Refilling.....................................................................................................13<br />

5.1 When does the Tensiometer needs to be refilled?.............................13<br />

5.2 Refilling in the lab................................................................................13<br />

5.3 Refilling in the field..............................................................................15<br />

5.4 Refilling with vacuum ..........................................................................16<br />

6 Calibration................................................................................................18<br />

6.1 Checking the offset.............................................................................18<br />

6.2 Offset correction for non horizontal installations...............................19<br />

6.3 Correlation of water column and pressure ........................................19<br />

7 Concept and installation...........................................................................20<br />

7.1 Selecting the measuring site................................................................20<br />

7.2 Selecting the installation angle ............................................................20<br />

7.2.1 "Vertical" with downwardly angle .............................................20<br />

7.2.2 "Horizontally" with upwardly angle ...........................................20

7.3 Number of Tensiometers per level ....................................................21<br />

7.4 Extend of the measuring site ..............................................................21<br />

7.5 Length of the refilling tubes ................................................................22<br />

7.6 Jacket tubes.........................................................................................22<br />

7.7 Ideal condition for installation.............................................................22<br />

7.8 Documentation...................................................................................23<br />

7.9 Installation...........................................................................................23<br />

8 Connecting the <strong>T8</strong> ...................................................................................25<br />

8.1 Single-ended or differential application...............................................25<br />

8.2 Connecting the IR-indicator................................................................26<br />

8.3 Wire specifications..............................................................................26<br />

9 Protecting the measuring site...................................................................27<br />

9.1 Theft and vandalism............................................................................27<br />

9.2 Frost ...................................................................................................27<br />

9.3 Lightning .............................................................................................27<br />

10 Additional notes..................................................................................29<br />

10.1 Interpretation and maximum measuring range..............................29<br />

10.2 Osmosis .........................................................................................30<br />

10.3 Emptying the <strong>T8</strong> ............................................................................30<br />

11 Accessories .........................................................................................31<br />

11.1 Connecting and extension cables...................................................31<br />

11.2 Handheld measuring device ...........................................................31<br />

11.3 Augers............................................................................................31<br />

11.4 Refill- and calibration kits ...............................................................32<br />

12 Contact and communication...............................................................33<br />

13 Technical specifications.......................................................................34<br />

5

1 Content of delivery<br />

The delivery of a <strong>T8</strong> includes:<br />

• Tensiometer, calibrated and filled, cable with plug and protective cap<br />

• This manual<br />

• Plastic bottle protecting the ceramic cup, must be filled to half with<br />

water to keep the cup moist<br />

• Shaft water protection disk<br />

• Calibration certificate with technical data and output signals<br />

Available accessories: see chapter "Accessories"<br />

If you wish to receive a individual calibration certificate for each Tensiometer,<br />

please contact us and give us the serial number of the Tensiometers.<br />

2 Short instructions<br />

Please read and understand the complete manual prior to first use.<br />

In general, the <strong>T8</strong> is filled and ready for installation when supplied.<br />

For installation proceed as follows:<br />

1. Drilling the borehole: An installation angle of 25° to 65° from the vertical<br />

line is ideal for the optimal removal of air from the cup. Mark the required<br />

drilling depth on the auger and on the Tensiometer shaft.<br />

Note: Installation depth = drilling depth / cos α<br />

Drill a borehole, diameter 25 mm, with the required depth. offers<br />

special Tensiometer gouge augers with shaped blade tip.<br />

2. Illuvation of the cup is only needed in clayey soils and only if the borehole is<br />

larger than the diameter of the cup (which is 24 mm). With the special<br />

Tensiometer gouge auger illuvation is unnecessary. In coarse sand and<br />

7

pebbly grounds a fine grained illuvation paste would even effect a water<br />

reservoir which would slow down the response.<br />

3. Take off the protective plastic bottle from the Tensiometer cup. Pull the<br />

bottle it off carefully or slowly turn it counter-clockwise!<br />

4. Insert the <strong>T8</strong> into the borehole up to the depth mark without using force.<br />

In clayey soils an overpressure might develop: Check the Tensiometer's<br />

pressure reading with an Infield measuring device or a datalogger!<br />

8<br />

Important: Pay attention to the engraved black spot on the<br />

end of the shaft that marks the position of the exit opening of<br />

the external filling inside the cup:<br />

a) Downwards installation: If the position of the cup will be<br />

lower than the end of the shaft, this mark must point<br />

upwards!<br />

b) Upwards installation: If the position of the cup<br />

will be higher than the end of the shaft, this mark<br />

must point downwards!<br />

5. Push down the shaft water retaining disk to a position directly on the soil<br />

surface. Water flowing down the shaft will not disturb measurements.<br />

6. Leave on the protective cap on the plug if the plug is not connected.<br />

7. Connect the Tensiometer signal wires as specified (see chapter 8<br />

Connecting the <strong>T8</strong>). If the measuring station is prepared , attach<br />

the Tensiometer plug to the suitable connecting cable.<br />

Notes:<br />

- The less air is inside the cup and the better the soil's conductivity is, the faster<br />

the Tensiometer will respond.<br />

- If the soil is dryer than 900 hPa, it does not make sense to refill the<br />

Tensiometer. Refill the Tensiometer as soon as the Tensiometer that is

installed in the next lower level has reached the reading when the upper<br />

Tensiometer had dried out.<br />

3 Safety notes<br />

Tensiometer are instruments for measuring the soil water tension, soil water<br />

pressure and soil temperature and are designed for this purpose only.<br />

Caution<br />

Lightning: Long cables act as antennas and might conduct surge voltage in<br />

case of lightning stroke – this might damage sensors and instruments.<br />

Caution<br />

Frost: Tensiometers are filled with water and therefore, are sensitive to<br />

frost! In wintertime, do not leave Tensiometers inside your car overnight.<br />

Generally, frost should not harm Tensiometers installed in depths below<br />

30 cm.<br />

Caution<br />

Overpressure: The non destructive maximum pressure is 3000 hPa. Higher<br />

pressure, which might occur for example during insertion in wet clayey<br />

soils or triaxial vessels, will destroy the pressure sensor! The applied<br />

pressure should not exceed 2000 hPa!<br />

Caution<br />

Electronics: Any electrical installations should only be executed by qualified<br />

personnel!<br />

Caution<br />

Ceramic cup: Avoid to touch the cup with your fingers. The ceramic<br />

should not have contact with grease or soap as this will influence the<br />

hydrophilic performance.<br />

9

4 Description of the <strong>T8</strong><br />

4.1 Output signals<br />

The <strong>T8</strong> is optimised for in-the-field use. Signals for soil water tension, soil<br />

temperature and filling status are offered.<br />

Water tension and temperature are linear voltage signals 0 ... 2 V. Thus, the<br />

signals are directly connectable to nearly any datalogger or other data<br />

recording device.<br />

The IR indicator works like a switch so the filling status can have two levels:<br />

"0V" (switch is open) for correct filling, or Vin = power supply voltage (switch<br />

is closed) if the Tensiometer needs to be refilled.<br />

4.2 Sensor body<br />

The complete electronic of the <strong>T8</strong> is integrated in the sensor body. The<br />

housing consists of glass-fibre reinforced synthetic. All electronic parts are<br />

completely covered with epoxy resin - the optimal and everlasting protection<br />

against moisture.<br />

The <strong>T8</strong> is calibrated electronically by<br />

programmable potentiometers. The calibration is<br />

stored in EPROM's.<br />

4.2.1 Pressure sensor<br />

The piezoelectric pressure sensor measures the soil water tension against the<br />

atmospheric pressure. The atmospheric pressure is conducted through a<br />

watertight diaphragm (the white, 2 cm long tube on the cable) and through the<br />

cable to the reference side of the pressure sensor.<br />

The non destructive maximum pressure is 3.000 hPa. Higher pressure will<br />

damage the sensor and absolutely must be avoided!<br />

10<br />

Sensors and refilling tube on sensor body

4.2.2 Temperature sensor<br />

A Pt1000 1/3 DIN B is used as temperature sensor. The Pt1000 has a<br />

maximum deviation of ±0.1 K at 0°C.<br />

The tip of the sensor dips into the Tensiometer cup's water. Thus, the best<br />

possible thermal contact to the soil is achieved.<br />

The correlation of water tension/water content is temperature depended. The<br />

influence is low with water tensions from 0 … 100 hPa ⇒ 0 … 6 hPa/K, but<br />

with tensions over 1000 hPa it is:<br />

Ψ = (R T/M) ln p/po Ψ = water tension R = gas constant (8,31J/mol K)<br />

M = molecular weight p = vapour pressure<br />

po = saturation vapour pressure at soil temperature<br />

(see vapour pressure tables by Scheffler/Straub, Grigull)<br />

4.2.3 IR indicator<br />

With the IR indicator the filling status of a <strong>T8</strong> in a downwardly installation can<br />

be checked without removing the Tensiometer from the soil.<br />

If the Tensiometer is installed in an upwardly angle (cup is higher than the<br />

end of the shaft), the indicator will react not before the cup is almost<br />

completely empty.<br />

Measuring principle of the IR indicator: A photo-sensor and a source of IR-light<br />

are integrated in the <strong>T8</strong> body. If there is only water between source and sensor<br />

the absorption is high and the photo-sensor will not respond. If there should be<br />

a bubble in-between, the measured light intensity arises and the electronic will<br />

switch to the high output signal, indicating the need to refill. The IR-"switch"<br />

can be burdened with 50 mA. LEDs or relays can be connected.<br />

Benefits of the IR indicator are an optimal service: If for example mounting rails<br />

with integrated LEDs are used, the user can check at a glance if all<br />

Tensiometers work well or which need to be refilled.<br />

11

Also, for quality assurance, the status of the signal can be logged for later<br />

evaluation of the readings.<br />

4.3 The ceramic cup<br />

Avoid to touch the cup with your fingers. The ceramic should not have<br />

contact with grease or soap as this will influence the hydrophilic<br />

performance.<br />

To transfer the soil water tension as a negative pressure into the Tensiometer,<br />

a semi-permeable diaphragm is required. This must have good mechanical<br />

stability and water-permeability, but also have gas impermeability.<br />

The <strong>T8</strong> cup consists of ceramic Al2O3 sinter material. The special<br />

manufacturing process guarantees homogeneous porosity with good water<br />

conductivity and very high firmness. Compared to conventional porous ceramic<br />

the cup is much more durable.<br />

The bubble point is higher than 6000 hPa. If the soil is dryer than 6000 hPa the<br />

negative pressure inside the cup decreases and the readings go down to 0 hPa.<br />

With these characteristics this material has outstanding suitability to work as<br />

the semi permeable diaphragm for Tensiometers.<br />

4.4 Reference air pressure<br />

The reference atmospheric air pressure is conducted to the pressure<br />

transducer via the air permeable (white) Teflon membrane and through the<br />

cable. The membrane does not absorb water. Water will not pass through the<br />

membrane into the cable, but condensed water inside the cable will leave the<br />

cable through the membrane.<br />

The white membrane on the cable must always have contact to air and<br />

should never be submersed into water.<br />

12

5 Refilling<br />

To assure a rapid and reliable measurement of the soil water tension, the cup<br />

must possibly be filled with de-ionised and degassed water and without bubbles<br />

of air. After dry periods or periods with a large number of wet and drying out<br />

successions, the <strong>T8</strong> must be refilled.<br />

For all refilling methods, the following items are always required:<br />

- Syringe with valve<br />

- Degassed, de-ionised water<br />

- Measuring device for Tensiometer pressure signal<br />

5.1 When does the Tensiometer needs to be refilled?<br />

The Tensiometer needs to be refilled:<br />

a, For Tensiometers installed "downwardly", the IR indicator will light up.<br />

b, If no signal peaks show up anymore.<br />

c, Tensiometers should not be refilled until the soil is moister than 900 hPa.<br />

If the soil gets dryer than 805 hPa, the readings will stop at the vapour pressure<br />

of water (i. e. 927 hPa at 20°C and atmospheric pressure of 950 hPa). By<br />

diffusion and slight leakage the reading will slowly drop within months.<br />

Still, if the soil dries out more than 6000 hPa, the negative pressure will drop<br />

much faster as air will enter the cup.<br />

5.2 Refilling in the lab<br />

To reach a measuring range of 900 hPa the Tensiometers should be refilled in<br />

the laboratory. With this refilling method a measuring range up to approx. 900<br />

hPa can be achieved (at 1013 hPa atmospheric pressure). A refill kit is required.<br />

Degassing procedure:<br />

1, Set up the refilling kit and connect the vacuum pump. The pump should<br />

achieve at least 30 hPa against vacuum (approx. 930 hPa).<br />

13

2, Unscrew the cup in clockwise direction and empty it. Do not touch the<br />

ceramic cup with your fingers. Wrap a clean towel around the cup.<br />

The pressure sensor diaphragm is inside the small boring on the pressure<br />

sensor body. It is very sensitive and may never be touched! It can be<br />

destroyed even by slightest contact! No contamination should get on the<br />

sealing and gasket.<br />

3, If the cup is drained it should be drenched in distilled water overnight by<br />

placing it in a beaker filled with water.<br />

Important: There should be no water inside the cup. The cup must be in an<br />

upright position so only the cup's outside is covered with water. Otherwise<br />

cavities of air might be enclosed inside the ceramic.<br />

4, The drenched cup should be empty. Insert the cup to the adapter and<br />

connect it to the degassing device. Place the cup in water in an upright<br />

position as described above.<br />

5, Fill the other adapter capsule to the half with water and insert the<br />

sensor body. Connect the adapter to the degassing device as well.<br />

6, Start the vacuum pump. With drenched cups, the procedure will take 4 to 5<br />

hours. From time to time, tap on cup and sensor body to loosen bubbles.<br />

Degassing is complete when no air bubbles ascend from ceramic and body<br />

and the cup is completely filled with water.<br />

14<br />

Beaker<br />

Ceramic<br />

cup<br />

Sensor<br />

body<br />

Vacuum<br />

bottle<br />

Pressure reducer<br />

Vacuum pump

7, Before screwing the cup onto the body, connect the sensor to a measuring<br />

device to observe the pressure signal. Carefully and slowly screw the cup on<br />

the sensor body. Make sure that no bubbles are enclosed.<br />

Caution: The pressure must not exceed 2000 hPa!<br />

8, Now, the cup and the pressure sensor are completely degassed. Finally, the<br />

refilling tubes have to be filled as well. To do so, continue with the<br />

procedure as described in chapter 5.3 or 5.4.<br />

5.3 Refilling in the field<br />

For an easy refilling of still saturated cups on site and without removing the<br />

Tensiometer from the soil, the Tensiometers can be refilled externally through<br />

the high-grade steel capillary tubes. If the refilling tubes are longer than 5 m a<br />

vacuum pump might be necessary – see chapter 5.4.<br />

Procedure:<br />

1. Connect the <strong>T8</strong> to the measuring device and keep an eye on the pressure<br />

signal at any time.<br />

2. Two steel capillary tubes come out from the <strong>T8</strong> shaft: the refilling tube and<br />

the de-airing tube. Pull off the rubber tube from the refilling tube.<br />

Left fig: Downwardly installation – the<br />

marked tube is the refilling tube<br />

Right fig: Upwardly installation – the<br />

marked tube is the de-airing tube<br />

15

2. Fill the syringe and the connected rubber tube with water. Attach the<br />

syringe to the refilling tube.<br />

3. Continuously inject water into the filling tube while monitoring the pressure<br />

signal at any time. Water and bubbles arise from the de-airing tube. Stop<br />

injecting water when no more air bubbles appear.<br />

16<br />

Caution: Do not let the pressure exceed 2000 hPa !<br />

4. Remove the syringe. Put a drop of water on both rubber and steel tube's<br />

end to avoid that any air will get into the tubes. Connect both.<br />

With this method a measuring range of approx. 800 hPa can be achieved.<br />

5.4 Refilling with vacuum<br />

To reach the full measuring range the Tensiometer water can be degassed<br />

even more completely by using a vacuum. This method can be applied for<br />

installed or not installed Tensiometers, in any installation angle and for refilling<br />

tubes longer than 5 m.<br />

The refilling kit BKTex contains all required tools:<br />

- manual vacuum pump and vacuum bottle with tube and valve<br />

- syringe with valve<br />

Procedure:<br />

1. Connect the <strong>T8</strong> to the measuring device and keep an eye on the pressure<br />

signal at any time. Pull off the rubber tube from the refilling tube.<br />

3, The syringe as well as the tube on the syringe should be filled with degassed<br />

water. Close the valve (!) and connect syringe and refilling tube.<br />

2, Connect vacuum bottle and de-airing tube. Now, evacuate the bottle to the<br />

maximum possible vacuum. This will enlarge the remaining bubble inside the<br />

cup. Briefly open and then close the valve of the syringe to let water flow<br />

into the Tensiometer. The air bubble will be sucked into the vacuum bottle.<br />

Repeat this 2 or 3 times until no bubbles come out anymore.

3, Close the valve of the vacuum tube and remove it. Now press down the<br />

syringe to fill in another amount of approx. 5 ml of water. Remove the<br />

syringe and connect both steel tubes with the rubber connecting tube.<br />

Fig: Downwardly installation – the marked tube is the refilling tube<br />

Fig: Upwardly installation – the marked tube is the de-airing tube<br />

17

6 Calibration<br />

Programmable potentiometers are integrated into the <strong>T8</strong>. They can be<br />

addressed via the two digital lines.<br />

Although the electronics is completely covered with epoxy resin, it is still<br />

possible to calibrate the sensor.<br />

The following parameters can be calibrated:<br />

• Pressure sensor: inclination and offset<br />

• Temperature sensor: offset<br />

• IR indicator: trigger level<br />

The <strong>T8</strong> Programming Unit KB<strong>T8</strong> is required to address the potentiometers<br />

and to check the inclination.<br />

6.1 Checking the offset<br />

There a two possible ways to check the offset:<br />

1. Put the filled <strong>T8</strong> into a beaker with water and immerse the cup for approx.<br />

3 to 4 cm. Wait for the value to stabilise. The measured signal must be<br />

between -5 hPa and +5 hPa (at room temperature). If air bubbles are inside<br />

the Tensiometer, the reading might take a while to reach this value.<br />

2. A more reliable method would be to screw of the cup. Then, shake the<br />

body to remove the water inside the pressure sensor. The pressure value<br />

must be in the range of -5 hPa to +5 hPa. Before screwing the cup on the<br />

<strong>T8</strong>-body, pressure sensor and cup must be refilled with degassed and deionised<br />

water (see chapter "Filling in the laboratory").<br />

Caution: The pressure sensor diaphragm inside the small boring on the<br />

pressure sensor body is very sensitive and may never be touched! It can be<br />

destroyed even by slightest contact!<br />

Also, no contamination should get on the sealing and gasket.<br />

18

6.2 Offset correction for non horizontal installations<br />

The <strong>T8</strong> is calibrated for horizontal installation. If it is built in a non horizontal<br />

position, the vertical water column drawing on the pressure sensor has to be<br />

compensated. With vertical installation (completely upright with 0° angle) the<br />

deviation is largest. In this case a water column of 5 cm additionally draws on<br />

the pressure sensor and causes a shift of -5 hPa. This means that a value of<br />

-5 hPa will be indicated instead of the actual value of 0 hPa.<br />

Find the correction value for other angles in the table:<br />

Angle to vertical line 0° 10° 15° 20° 25° 30°<br />

Offset correction in [hPa] = [mV] -5 -4,9 -4,8 -4,7 -4,5 -4.3<br />

Angle to vertical line 45° 60° 70° 75° 80° 90°<br />

Offset correction in [hPa] = [mV] -3,5 -2.5 -1,7 -1,3 -0,9 0<br />

6.3 Correlation of water column and pressure<br />

A precision pressure gauge or a water column is needed. Please also observe<br />

the correlation of pressure and water column if the Tensiometer is used as a<br />

piezometer or water level transmitter.<br />

Pressure = density x gravity x height<br />

Density of water at 20°C: 0,998205 kg/cubic decimetres; at 4°C: 1,0 kg/dm3 .<br />

[Pa] = [N]/[qm] [N] = [kg/m qsec]<br />

[kg] = [Pa qm/m] [Pa] = kg/[qqm qsec]<br />

A water column of 1 meter causes a pressure p of:<br />

p [Pa= N/qm] = 998,205 kg/qqm x 9,81 m/qs x 1m<br />

p = 9792,39 [N/qm x Pa qs/m /qqm x m/qs x m] = 97,92 hPa<br />

In reverse a pressure of 100 hPa at 20°C is caused by a water column of<br />

102,15 cm.<br />

19

7 Concept and installation<br />

7.1 Selecting the measuring site<br />

The installation spot should be representative for the soil horizon! Therefore,<br />

in heterogenic soils, classifying drillings should be made before or during<br />

installation.<br />

On farmed sites with vegetation root spreading and root growth during the<br />

measuring period must be considered. Fine roots will grow around the<br />

Tensiometer cup as this is a poor but still secure source of water. Therefore,<br />

avoid the root zone or move the Tensiometer from time to time depending on<br />

the root growth.<br />

Disturbing effects like waysides, the rim of a field, slopes or dints must be<br />

avoided or considered in the interpretation of the measuring results.<br />

7.2 Selecting the installation angle<br />

An installation position would be ideal if the typical water flow is not disturbed<br />

by the Tensiometer. No preferential water flow along the shaft should be<br />

created. Therefore, Tensiometers are preferably installed at an angle.<br />

7.2.1 "Vertical" with downwardly angle<br />

When installed from the surface, an angle of 25° to 65° from the<br />

vertical line is optimal for refilling. In an absolutely vertical position<br />

air bubbles might hide inside the edges of the cup adapter. Still,<br />

they could be removed completely with the vacuum refilling kit<br />

BKTex. In this position, the refilling tube is the shorter stainless<br />

steel tube with the black mark. Into this tube, water is injected for<br />

refilling.<br />

7.2.2 "Horizontal" with upwardly angle<br />

When installed horizontally from inside a well or pit hole,<br />

the Tensiometer must point upwards! This means the<br />

20

cup is in a higher position than the end of the shaft. An upward angle of approx.<br />

5° is ideal for refilling. Note that now de-airing and refilling tube are switched:<br />

the refilling tube is the longer stainless steel tube without the black mark. Into<br />

this tube, water is injected for refilling.<br />

The IR-indicator will react not until at least a half of the cup is empty.<br />

7.3 Number of Tensiometers per level<br />

To verify the results, at least three Tensiometers per soil level and with the<br />

identical soil, vegetation and climatic conditions should be implemented. Thus,<br />

irregular values as well as the variableness of the water situation can be<br />

determined. Guiding principle: More heterogeneous sites and soil structures<br />

require a higher number of Tensiometers.<br />

7.4 Extend of the measuring site<br />

Large distance along with high equidistance between the measuring spots will<br />

reduce the influence of sectional heterogeneity. Therefore, equidistant spots<br />

are mostly used to measure the heterogeneity of the soil, the cultivation or the<br />

observed development.<br />

The following points limit the maximum length for the signal cables:<br />

- Required accuracy: In single-ended applications every 20 m of cable reduces<br />

the accuracy for about 2 hPa or 0,1°C. (Please read chapter "Connecting<br />

the <strong>T8</strong>" on how to compensate the voltage drop of sensors which are<br />

connected single-ended.)<br />

- Local danger of lightning stroke: Cables act as antennas and therefore<br />

should be as short as possible.<br />

Lengths of more than 100 m are possible but not recommendable. The<br />

available connecting cables are described in the chapter "Accessories".<br />

21

7.5 Length of the refilling tubes<br />

Keep the refilling tubes as short as possible. Caused by the thermal expansion<br />

of air, any air inside the tubes will affect the readings when temperature<br />

changes. Preferably, insulate the refilling tubes or install them isothermal into<br />

the soil.<br />

7.6 Jacket tubes<br />

Jacket tubes are useful with shafts longer than 2 m, in pebbly soils or gravel,<br />

and for horizontal installations from inside a well or pit hole. The jacket tube<br />

should end 30 to 50 cm away from the cup so leaking or condensation water is<br />

not conducted to the cup. The inner diameter of the jacket tube should be at<br />

least 35 mm.<br />

7.7 Ideal condition for installation<br />

For the installation of Tensiometers, the ideal conditions are:<br />

- Frost-free soil.<br />

- Coarse clay or loess.<br />

- In soil types loess, coarse clay, loam or clay as well as in highly organic soils<br />

(humus) preferably with a water tension close to saturation (moist).<br />

- In sandy or pebbly soils with a water tension over 100 hPa (rather dry).<br />

- Low skeletal structure (gravel). The more gravel in a soil the more often<br />

the drilling has to be repeated to reach the required depth.<br />

22

7.8 Documentation<br />

For every measuring spot you should:<br />

- Measure out the position where the pressure sensor will be placed. (A must<br />

for installations below the ground surface).<br />

- Take documenting photos before, during and after installation.<br />

- Save a soil sample.<br />

- Write down installation depth and angle with each sensor identification<br />

(serial number).<br />

- Mark all connecting cables with the corresponding sensor identification on<br />

each end.<br />

7.9 Installation<br />

For the installation of the <strong>T8</strong> in the field the following tools are required:<br />

• Tensiometer auger with diameter 25 mm, ideally the<br />

Tensiometer gouge auger with shaped blade tip.<br />

• Rule, spirit level, goniometer, marker pen<br />

• Minute book, maybe camera for documentation of site and soil profile<br />

• Perhaps PE-plastic bags for taking soil samples from the site<br />

Installation procedure:<br />

1. Measure and mark the required drilling depth on auger and Tensiometer<br />

shaft. Drill a hole with the desired depth on the chosen measuring spot.<br />

Read the chapter "Selecting the installation position" for the best installation<br />

angle. Be cautious with the last 20 cm and take out and save this soil.<br />

2. For soils with poor capillary contact or when using augers with a diameter of<br />

over 25 mm, mix a paste of water and crumbled soil material taken out of<br />

the borehole. Fill the paste into the bottom area of the borehole using a<br />

tube (diameter 20 mm).<br />

3. Take off the protective plastic cap from the Tensiometer cup.<br />

23

Important: Only turn of the cap counter-clockwise! Do not store the<br />

Tensiometer without the protective plastic bottle since the cup drains fast!<br />

The bottle must be filled with some water for storage!<br />

4. Connect the Tensiometer to a readout unit. Carefully insert the <strong>T8</strong> into the<br />

borehole up to the stop.<br />

24<br />

Do not use any force. The Tensiometer may not be pounded, since cup or<br />

pressure sensor can be destroyed.<br />

Especially in clayey soils the pressure reading must be monitored as high<br />

pressures might build up! The maximum pressure must not exceed 2000<br />

hPa<br />

5. Push the shaft water retaining disk down to cover the soil surface. This<br />

prevents water from running into the borehole and down along the shaft.<br />

6. Keep the protective plastic cap on the plug whenever the plug is not<br />

connected!<br />

7. Connect the signal cables as described in the chapter "Connecting the <strong>T8</strong>".<br />

8. The Tensiometer will respond to changes in the soil water tension faster if<br />

there is no air inside the system and the soil water conductivity/mobility is<br />

high.<br />

9. Write down serial number, position, installation angle and depth.

8 Connecting the <strong>T8</strong><br />

The <strong>T8</strong> is fitted with an 8-pin plug. The plug can be connected to a Infield 7<br />

handheld measuring device. The Infield 7 displays and stores the soil water<br />

tension, the soil temperature and the filling status.<br />

With the extension cables offered as accessories the <strong>T8</strong> can be<br />

connected to a Datalogger or any other data acquisition devices.<br />

Please observe the max. supply voltage of 20 VDC. Never connect the signal<br />

outputs of the <strong>T8</strong> to a supply voltage source!<br />

The Tensiometer plug must be covered with the added protective cap<br />

anytime the <strong>T8</strong> is not connected to an extension cable.<br />

8.1 Single-ended or differential application<br />

In general a datalogger with differential inputs should be preferred. This means<br />

both the plus signal as well as the minus signal of each sensor are measured. On<br />

many dataloggers less channels are required for single-ended measurements,<br />

which means only the plus signals are measured and related to the common<br />

sensor supply ground. In this case, the voltage drop, depending on the current<br />

consumption and the cable resistance, influences the reading and must be<br />

compensated:<br />

Current consumption: 7 mA; cable resistance: 82 Ω/km<br />

⇒ Voltage drop inside a cable with length 10 m:<br />

UError = R x I = 0,82 Ω x 0,007 A = 5,66 mV<br />

⇒ Error for water tension (1 mV equal to 1 hPa): 5,66 mV = 5,66 hPa<br />

⇒ Error for temperature (1°C equal to 20 mV): 5,66 mV = 0,283 °C<br />

Therefore, the characteristic lines are lifted for +5,66 hPa resp. +0,283 °C per<br />

10 m cable. The incline is not influenced. For each 10 meters of cable,<br />

withdraw 5,66 hPa for pressure (Note: the water tension signal is regarded<br />

positive) and 0,283 °C for temperature from the measured signal value to get<br />

the correct reading.<br />

25

8.2 Connecting the IR-indicator<br />

Some datalogger types require a pull-down resistor (for example 10 kOhm)<br />

against ground for the IR-indicator. Other logger types already have an internal<br />

pull-down resistor, or a pull-up resistor to 5 V, for example for connecting a<br />

reed switch. The external pull-down resistor must be smaller than the logger<br />

internal pull-up resistor or at least be in a relation so the logger will recognize<br />

the zero level.<br />

8.3 Wire specifications<br />

26<br />

white = V in Power supply plus, 6 … 20 V DC<br />

brown = GND Power supply minus<br />

green = Signal + Soil water tension plus<br />

red = Signal Temp Temperature plus<br />

yellow = Signal - Minus for soil water tension and temperature<br />

grey = Signal IR IR-indicator, switched with Vin pink = Calibration SDA (digital)<br />

blue = Calibration SCL (digital)

9 Protecting the measuring site<br />

9.1 Theft and vandalism<br />

The site should be protected against theft and vandalism as well as against any<br />

farming or field work. Therefore, the site should be fenced and signposts could<br />

give information about the purpose of the site. Cables should be protected<br />

against rodents.<br />

9.2 Frost<br />

Tensiometer are filled with water and therefore are endangered by frost!<br />

With temperatures below–5°C do not leave filled Tensiometers in your car,<br />

in a measuring hut, etc.<br />

Do not fill the Tensiometers with Ethanol, as this is corrosive for some<br />

materials (i. e. PMMA) and might destroy these..<br />

Also it is not recommendable to fill the Tensiometers with Decalin, monoethylene-glycol,<br />

di-ethylene-glycol, etc. These could harm any of the materials,<br />

destroy the ceramic cup or leak into the soil.<br />

Specially designed Tensiometers which can be filled with Ethanol are available<br />

on request. They can be used to temperatures down to - 20°C.<br />

9.3 Lightning<br />

Measuring instruments in the field are always endangered by over-voltages.<br />

Whenever technically feasible, over-voltage and false polarity protection are<br />

realised. If you have questions about an optimal integration of the <strong>T8</strong> into a<br />

measuring system, please contact our system engineers.<br />

Still, there is no absolute certain lightning protection! Lightning strokes are not<br />

predictable. The more extensive a site is, the more import is the installation of<br />

a protection system which could be passive with ground spears – preferably<br />

27

with groundwater contact, or active with each sensor and logger individually<br />

equipped with a lightning protection module. This normally is quite costly.<br />

28

10 Additional notes<br />

10.1 Interpretation and maximum measuring range<br />

Since no pressure smaller than vacuum can appear in the Tensiometer, the<br />

atmospheric pressure (reference pressure) limits the measuring range of the<br />

Tensiometers. Additionally the measuring range is reduced by the vapour<br />

pressure of the Tensiometer's filling water, depending on the temperature.<br />

At 20 °C the vapour pressure is 23.4 hPa. The maximum measuring range at an<br />

atmospheric pressure of 950 hPa is calculated as:<br />

950 hPa - 23.4 hPa = 926.6 hPa<br />

The vapour pressure exponentially rises with temperature. A higher ambient<br />

temperature and lower atmospheric pressure reduces the measuring range.<br />

The above considerations are ruled out by the boiling point shift, enabling a<br />

Tensiometer to measure beyond the vapour pressure. This status is<br />

reproducible, but cannot be quantified.<br />

If the soil gets dryer than 850 hPa the reading will halt at the value of the steam<br />

point (i. e. 927 hPa at 20°C and 950 hPa atmospheric pressure) By diffusion and<br />

minor leakage this value will drop within months.<br />

If the soil gets dryer than 10000 hPa the reading will drop much faster as air<br />

will enter the cup. Evaluating this will give further information, especially if<br />

measurements are taken with TDR probes at the same time, as with this the<br />

extrapolation of the pF-curve in the range of 850 … 10000 hPa determined.<br />

Vapour pressure influence on water tension/water content relation:<br />

If temperature rises from 20°C to 25°C in a soil sample with constant water<br />

content, the water tension gets smaller about 8.5 hPa.<br />

Temperature 4°C 10°C 16°C 20°C 25°C 30°C 50°C 70°C<br />

Change of pressure per 0,6 0,9 1,2 1,5 1,9 2,5 7,2 14<br />

Kelvin in [hPa]<br />

29

10.2 Osmosis<br />

The ceramic used has a pore size of 1 µm. Thus, ions can hardly be kept out.<br />

An influence of the measured value by osmotic effect is negligible under normal<br />

circumstances. If the <strong>T8</strong> is dipped into saturated NaCl solution 10 hPa are<br />

measured. Either consider this fault or fill the water with this solution (after it<br />

has been degassed).<br />

10.3 Emptying the <strong>T8</strong><br />

Freezing of the Tensiometer water will destroy the pressure sensor and<br />

possibly the cup. Therefore, frost endangered Tensiometer must be<br />

removed from the soil or emptied.<br />

In non-freezing depths Tensiometers can remain in the ground in winter.<br />

Procedure for emptying:<br />

1. Remove the connecting rubber tube from the refilling tube.<br />

2. Connect the empty syringe to the refilling tube.<br />

3. Completely suck out the Tensiometer water.<br />

4. Connect rubber tubes and filing tube.<br />

Until now, we received no tensiometer with freezing damage while installed in<br />

the soil deeper than 30 cm, although the soil was frozen.<br />

30

11 Accessories<br />

The following equipment is available:<br />

11.1 Connecting and extension cables<br />

Connecting cables for connections to dataloggers, etc.. One end with female<br />

plug M12/IP67 for connection to a Tensiometer, the other end with loose<br />

wires:<br />

article: CC-8/5 (length 5 m)<br />

CC-8/10 (length 10 m)<br />

CC-8/20 (length 20 m)<br />

Extension cables with one each male and female plug M12/IP67:<br />

article: EC-8/10 (length 10 m)<br />

EC-8/20 (length 20 m)<br />

Individual lengths on request.<br />

11.2 Handheld measuring device<br />

Infield 7 handheld measuring device for manual readings (with or<br />

without calibration function). article: INFIELD7.<br />

11.3 Augers<br />

Tensiometer gouge auger with specially shaped blade. The tip of the blade has<br />

the same shape and diameter as the Tensiometer cup, so no illuvation with clay<br />

paste is necessary. article: TB-25<br />

31

11.4 Refill and calibration kits<br />

32<br />

BKTex<br />

Refill kit for external refillable Tensiometer, including<br />

manual vacuum pump, 250 ml coated glass bottle,<br />

refill syringe, pipes and valves. article: BKTex<br />

BKT468<br />

Refill kit for Tensiometer, incl. base stand with<br />

clamps, adapter that fits to T4, T6 and <strong>T8</strong>-sensor<br />

bodies, 500 ml bottle, pressure gauge, tubes, beaker,<br />

refilling syringe. article: BKT468<br />

KB<strong>T8</strong><br />

Calibration kit for <strong>T8</strong> with calibrator for digital balance, offset, incline; incl.,<br />

precision manometer, valve, mounting kit, vacuum tube, requires a precision<br />

voltmeter. article: KB<strong>T8</strong><br />

All glass vacuum bottles are plastic covered and implosion proof.

12 Contact and communication<br />

Please take advantage of our consulting service – we want you to achieve<br />

optimal results with our instruments.<br />

With pleasure we would like to receive your comments, inspirations, critics.<br />

P.O. Box 4, 6987 ZG Giesbeek<br />

Nijverheidsstraat 30,<br />

6987 EM Giesbeek,<br />

The Netherlands<br />

T +31 313 880200<br />

F +31 313 632167<br />

E eijkelkamp@eijkelkamp.com<br />

I http://www.eijkelkamp.com<br />

33

13 Technical specifications<br />

Dimension, material<br />

Ceramic<br />

Length 60 mm, diameter 24 mm<br />

Sensor body<br />

Material PA6<br />

Shaft<br />

Material PMMA, diameter 25 mm<br />

Cable<br />

Standard cable length<br />

with shafts < 120 cm 1,5 m from sensor body<br />

with shaft > 121 cm 0,6 m from end of shaft<br />

Plug 8-pin, thread M12,<br />

protective rate IP67 (waterproof)<br />

Measuring range<br />

Soil water tension<br />

electronically -1000 hPa ... +1000 hPa<br />

physically<br />

-1000 hPa ... +850 hPa<br />

Temperature -30 ... +70°C<br />

Signal<br />

Soil water tension 0 ... 2 V = -1000 hPa ... +1000 hPa<br />

Temperature<br />

0 ... 2 V = -30 ... +70°C<br />

IR-indicator<br />

Switch open: refilling ok<br />

Switch closed (Vin): refilling required;<br />

max. burden 50mA<br />

Accuracy<br />

Soil water tension ± 5 hPa<br />

Temperature<br />

± 0,2 K (-10...+30°C); ± 0,4 K<br />

Supply<br />

Power supply 6 ... 20 V<br />

Current consumption 7 mA<br />

34