FLAIL MOWERS PRE-OPERATION Inspection - McConnel

FLAIL MOWERS PRE-OPERATION Inspection - McConnel

FLAIL MOWERS PRE-OPERATION Inspection - McConnel

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

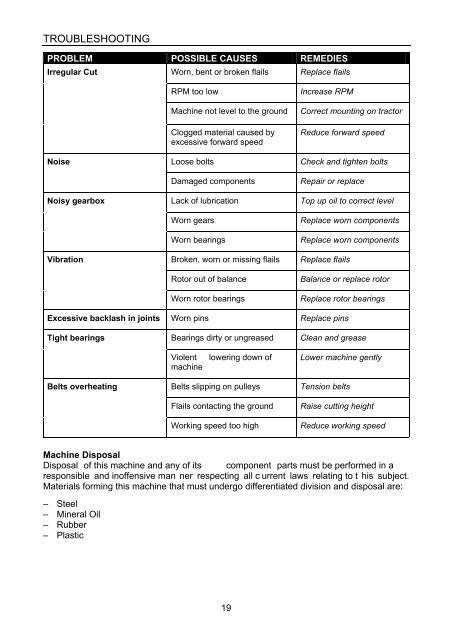

TROUBLESHOOTING<br />

PROBLEM POSSIBLE CAUSES REMEDIES<br />

Irregular Cut<br />

Noise<br />

Noisy gearbox<br />

Vibration<br />

Worn, bent or broken flails<br />

RPM too low<br />

Machine not level to the ground<br />

Clogged material caused by<br />

excessive forward speed<br />

Loose bolts<br />

Damaged components<br />

Lack of lubrication<br />

Worn gears<br />

Worn bearings<br />

Broken, worn or missing flails<br />

Rotor out of balance<br />

Worn rotor bearings<br />

Excessive backlash in joints Worn pins<br />

Tight bearings<br />

Belts overheating<br />

Bearings dirty or ungreased<br />

Violent lowering down of<br />

machine<br />

Belts slipping on pulleys<br />

Flails contacting the ground<br />

Working speed too high<br />

19<br />

Replace flails<br />

Increase RPM<br />

Correct mounting on tractor<br />

Reduce forward speed<br />

Check and tighten bolts<br />

Repair or replace<br />

Top up oil to correct level<br />

Replace worn components<br />

Replace worn components<br />

Replace flails<br />

Balance or replace rotor<br />

Replace rotor bearings<br />

Replace pins<br />

Clean and grease<br />

Lower machine gently<br />

Tension belts<br />

Raise cutting height<br />

Reduce working speed<br />

Machine Disposal<br />

Disposal of this machine and any of its component parts must be performed in a<br />

responsible and inoffensive man ner respecting all c urrent laws relating to t his subject.<br />

Materials forming this machine that must undergo differentiated division and disposal are:<br />

– Steel<br />

– Mineral Oil<br />

– Rubber<br />

– Plastic