Developments in vacuum drying and press drying of

Developments in vacuum drying and press drying of

Developments in vacuum drying and press drying of

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Center for<br />

Forest Products<br />

Pr<strong>of</strong>. Dr. Ressel<br />

Introduction<br />

Fundamentals<br />

Plant Facilities<br />

Innovations<br />

Process<br />

Technology<br />

Plant Examples<br />

Brunner<br />

IWT<br />

Mühlböck<br />

Kronseder<br />

Eberl<br />

Opel<br />

HeatWave<br />

Press Dry<strong>in</strong>g<br />

����������� � �� ����<br />

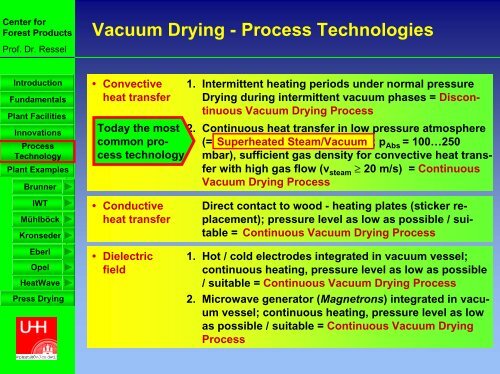

Vacuum Dry<strong>in</strong>g - Process Technologies<br />

• Convective 1. Intermittent heat<strong>in</strong>g periods under normal <strong>press</strong>ure<br />

heat transfer Dry<strong>in</strong>g dur<strong>in</strong>g <strong>in</strong>termittent <strong>vacuum</strong> phases = Discont<strong>in</strong>uous<br />

Vacuum Dry<strong>in</strong>g Process<br />

Today the most 2. Cont<strong>in</strong>uous heat transfer <strong>in</strong> low <strong>press</strong>ure atmosphere<br />

common pro- (= Superheated Steam Steam/Vacuum / Vacuum; pAbs = 100…250<br />

cess technology mbar), sufficient gas density for convective heat transfer<br />

with high gas flow (vsteam ≥ 20 m/s) = Cont<strong>in</strong>uous<br />

Vacuum Dry<strong>in</strong>g Process<br />

• Conductive Direct contact to wood - heat<strong>in</strong>g plates (sticker reheat<br />

transfer placement); <strong>press</strong>ure level as low as possible / suitable<br />

= Cont<strong>in</strong>uous Vacuum Dry<strong>in</strong>g Process<br />

• Dielectric 1. Hot / cold electrodes <strong>in</strong>tegrated <strong>in</strong> <strong>vacuum</strong> vessel;<br />

field cont<strong>in</strong>uous heat<strong>in</strong>g, <strong>press</strong>ure level as low as possible<br />

/ suitable = Cont<strong>in</strong>uous Vacuum Dry<strong>in</strong>g Process<br />

2. Microwave generator (Magnetrons) <strong>in</strong>tegrated <strong>in</strong> <strong>vacuum</strong><br />

vessel; cont<strong>in</strong>uous heat<strong>in</strong>g, <strong>press</strong>ure level as low<br />

as possible / suitable = Cont<strong>in</strong>uous Vacuum Dry<strong>in</strong>g<br />

Process