Developments in vacuum drying and press drying of

Developments in vacuum drying and press drying of

Developments in vacuum drying and press drying of

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Center for<br />

Forest Products<br />

Pr<strong>of</strong>. Dr. Ressel<br />

Introduction<br />

Fundamentals<br />

Plant Facilities<br />

Innovations<br />

Process<br />

Technology<br />

Plant Examples<br />

Brunner<br />

IWT<br />

Mühlböck<br />

Kronseder<br />

Eberl<br />

Opel<br />

HeatWave<br />

Press Dry<strong>in</strong>g<br />

����������� � �� ����<br />

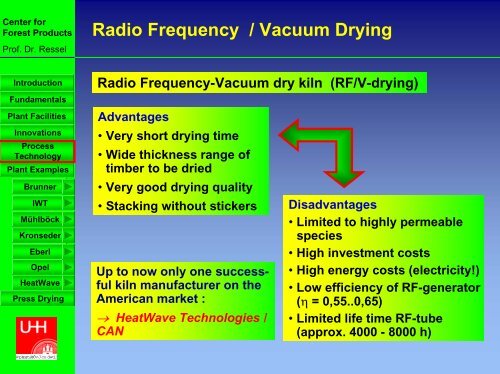

Radio Frequency / Vacuum Dry<strong>in</strong>g<br />

Radio Frequency-Vacuum dry kiln (RF/V-dry<strong>in</strong>g)<br />

Advantages<br />

• Very short dry<strong>in</strong>g time<br />

• Wide thickness range <strong>of</strong><br />

timber to be dried<br />

• Very good dry<strong>in</strong>g quality<br />

• Stack<strong>in</strong>g without stickers<br />

Up to now only one successful<br />

kiln manufacturer on the<br />

American market :<br />

→ HeatWave Technologies /<br />

CAN<br />

Disadvantages<br />

• Limited to highly permeable<br />

species<br />

• High <strong>in</strong>vestment costs<br />

• High energy costs (electricity!)<br />

• Low efficiency <strong>of</strong> RF-generator<br />

(η = 0,55..0,65)<br />

• Limited life time RF-tube<br />

(approx. 4000 - 8000 h)