Developments in vacuum drying and press drying of

Developments in vacuum drying and press drying of

Developments in vacuum drying and press drying of

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Center for<br />

Forest Products<br />

Pr<strong>of</strong>. Dr. Ressel<br />

Introduction<br />

Fundamentals<br />

Plant Facilities<br />

Innovations<br />

Process<br />

Technology<br />

Plant Examples<br />

Brunner<br />

IWT<br />

Mühlböck<br />

Kronseder<br />

Eberl<br />

Opel<br />

HeatWave<br />

Press Dry<strong>in</strong>g<br />

����������� � �� ����<br />

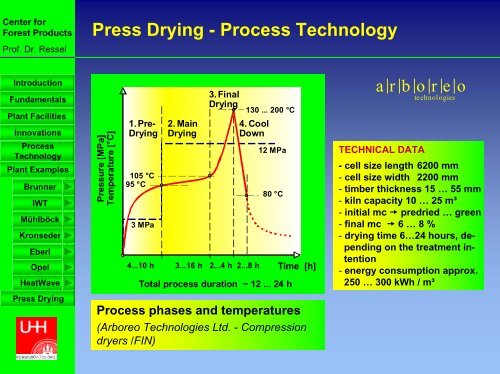

Press Dry<strong>in</strong>g - Process Technology<br />

1. Pre-<br />

Dry<strong>in</strong>g<br />

105 °C<br />

95 °C<br />

3 MPa<br />

2. Ma<strong>in</strong><br />

Dry<strong>in</strong>g<br />

3. F<strong>in</strong>al<br />

Dry<strong>in</strong>g<br />

130 ... 200 °C<br />

4. Cool<br />

Down<br />

4...10 h 3...16 h 2...4 h 2...8 h<br />

12 MPa<br />

80 °C<br />

Total process duration ~ 12 ... 24 h<br />

Time [h]<br />

Process phases <strong>and</strong> temperatures<br />

(Arboreo Technologies Ltd. - Com<strong>press</strong>ion<br />

dryers /FIN)<br />

a r b o r e o<br />

technologies<br />

TECHNICAL DATA<br />

- cell size length 6200 mm<br />

- cell size width 2200 mm<br />

- timber thickness 15 … 55 mm<br />

- kiln capacity 10 … 25 m³<br />

- <strong>in</strong>itial mc � predried … green<br />

- f<strong>in</strong>al mc � 6 … 8 %<br />

- dry<strong>in</strong>g time 6…24 hours, depend<strong>in</strong>g<br />

on the treatment <strong>in</strong>tention<br />

- energy consumption approx.<br />

250 … 300 kWh / m³