antimony - Sciencemadness.org

antimony - Sciencemadness.org

antimony - Sciencemadness.org

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

THE METALLURGY OF ANTIMONY. 103<br />

B. Methods for the Production of Metallic Antimony.<br />

1. Eeduction of the Oxide.—The object of this is to reduce the<br />

oxide (trioxide or tetroxide) to metallic <strong>antimony</strong>, commonly called<br />

<strong>antimony</strong> regulus. Now, if coal were the only agent used for the<br />

reduction, there would be a great loss due to volatilisation, and, in<br />

addition, some unaltered sulphide of <strong>antimony</strong> in the roasted<br />

ore. Therefore alkaline substances like potash, soda, Glauber salt,<br />

etc., are added in order to form a fusible slag, which, being lighter<br />

than the metal produced, would form a cover over the metallic bath,<br />

thus preventing any possible volatilisation, and would dissolve any<br />

sulphide of <strong>antimony</strong> present. This slag also serves as a refining<br />

medium, removing any impurities present from the final metallic<br />

product.<br />

The working expenses of the roasting and reduction process are<br />

less than those of the precipitation method, and hence it is suitable<br />

for the working of poorer ores and liquation residues, while the<br />

latter can only be adopted—and even then very rarely—when ore<br />

is rich, but coal and labour cheap.<br />

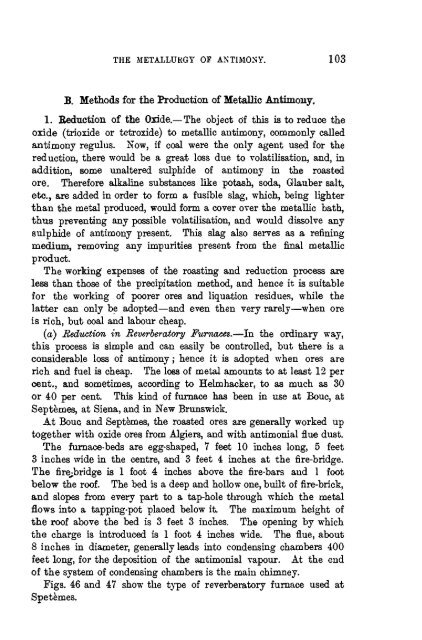

(a) Reduction in Reverberatory Furnaces.—In the ordinary way,<br />

this process is simple and can easily be controlled, but there is a<br />

considerable loss of <strong>antimony</strong>; hence it is adopted when ores are<br />

rich and fuel is cheap. The loss of metal amounts to at least 12 per<br />

cent., and sometimes, according to Helmhacker, to as much as 30<br />

or 40 per cent. This kind of furnace has been in use at Bouc, at<br />

Septemes, at Siena, and in New Brunswick.<br />

At Bouc and Septemes, the roasted ores are generally worked up<br />

together with oxide ores from Algiers, and with antimonial flue dust.<br />

The furnace-beds are egg-shaped, 7 feet 10 inches long, 5 feet<br />

3 inches wide in the centre, and 3 feet 4 inches at the fire-bridge.<br />

The fire-bridge is 1 foot 4 inches above the fire-bars and 1 foot<br />

below the roof. The bed is a deep and hollow one, built of fire-brick,<br />

and slopes from every part to a tap-hole through which the metal<br />

flows into a tapping-pot placed below it. The maximum height of<br />

the roof above the bed is 3 feet 3 inches. The opening by which<br />

the charge is introduced is 1 foot 4 inches wide. The flue, about<br />

8 inches in diameter, generally leads into condensing chambers 400<br />

feet long, for the deposition of the antimonial vapour. At the end<br />

of the system of condensing chambers is the main chimney.<br />

Figs. 46 and 47 show the type of reverberatory furnace used at<br />

Spetemes.