antimony - Sciencemadness.org

antimony - Sciencemadness.org

antimony - Sciencemadness.org

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

THE ANTIMONY PREPARATIONS AND THEIR USES. 165<br />

has been found native in the lavas of Vesuvius. There exist many<br />

processes for manufacturing it. According to Brunner, a German<br />

chemist, it can be produced thus:—A mixture of 2 parts of tartar<br />

emetic and 4 parts .of marine salt is calcined gently in a Hesse<br />

crucible just to the point of fusion. After cooling, the mass is<br />

crushed and then washed with water.<br />

(fi) Messrs Hallet and J. Stenhouse in 1861 took out a patent in<br />

England for manufacturing <strong>antimony</strong> yellow. This is produoed by<br />

using *the oxides and the sulphides of <strong>antimony</strong>, with variable proportions<br />

of <strong>antimony</strong>, oxide of iron, silica, water, and sometimes<br />

arsenic, giving rise to various hues from a light yellow to a yellowish<br />

red. The gangue is removed as far as possible by picking and<br />

washing the ore, after which it is ground and sifted. The ground<br />

mass is introduced into large crucibles, muffles, or reverberatory<br />

furnaces, where it is carefully calcined at a dull red heat with access<br />

of air. The mass is constantly stirred in order to prevent too high<br />

an elevation of its temperature. During the operation, the powder<br />

emits steam, sulphur, sulphurous acid, fumes of <strong>antimony</strong> and<br />

arsenic, and becomes less fusible. The calcination lasts for from two<br />

to three hours, and is completed when vapours and fumes are no longer<br />

disengaged and when all the <strong>antimony</strong> has been transformed into<br />

anhydrous antimonious acid. The impure antimonious acid is<br />

reduced to an impalpable powder by grinding and levigation. After<br />

drying, it forms with oil, varnish, etc., a pigment which may be combined<br />

with oxides or salts, such as zinc oxide, white lead, chromate<br />

of lead. The yellow pigment is obtained when the following constituents<br />

are mixed together: 8 parts of native oxide of <strong>antimony</strong>, or<br />

of the oxide mixed with the sulphide, or the impure antimonious<br />

oxide obtained by the above-mentioned process; 3 parts of red lead or<br />

litharge; and 1 part of oxide of zinc. This mixture is powdered and<br />

calcined in crucibles, muffles, or furnaces, until combination is<br />

effected and the final yellow colour has appeared. The mass is then<br />

finally powdered and ground in oil or in varnish. By varying the<br />

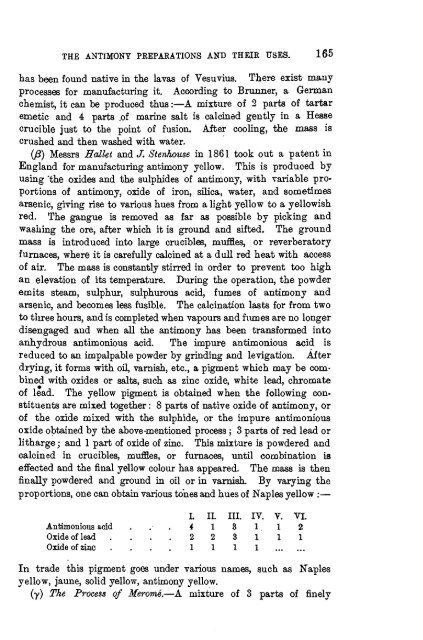

proportions, one can obtain various tones and hues of Naples yellow :—<br />

Antiinonious acid<br />

Oxide of lead<br />

Oxide of zinc<br />

In trade this pigment goes under various names, such as Naples<br />

yellow, jaune, solid yellow, <strong>antimony</strong> yellow.<br />

(y) The Process of Merome.—A mixture of 3 parts of finely<br />

I.<br />

i21<br />

II.<br />

1<br />

2 1<br />

III.<br />

331<br />

IV.<br />

111<br />

V.<br />

11<br />

VI.<br />

21