antimony - Sciencemadness.org

antimony - Sciencemadness.org

antimony - Sciencemadness.org

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

88<br />

THE METALLURGY OF ANTIMONY.<br />

is introduced into a blast furnace or a cupola with 10 per cent, of<br />

coal. If the mineral is an oxide, then 25 per cent, of coal is required.<br />

In immediate connection with the furnace or cupola is a chamber<br />

for the condensation of the volatile oxide thus produced, and beyond<br />

it a reservoir containing water for the condensation of the last trace<br />

of the volatile trioxide. The practical working of this process may<br />

thus be summarised:—200 lbs. of coal are burned in the furnace or<br />

cupola; on it is put one ton of sulphide ore or 800 lbs. of oxide ore;<br />

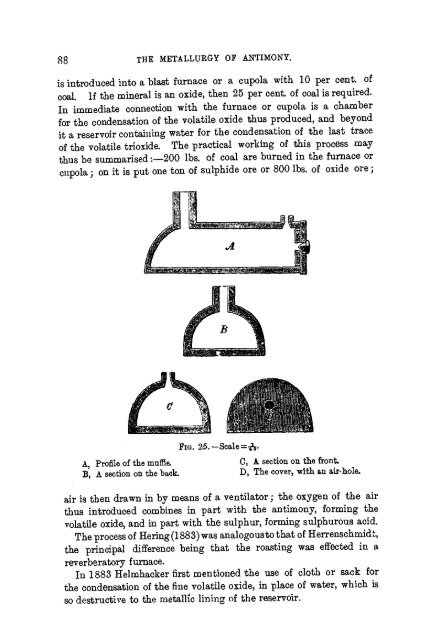

FIG. 25.—Scale=^.<br />

A, Profile of the muffle. C, A section on the front<br />

B*, A section on the back. D, The cover, with an air-hole.<br />

air is then drawn in by means of a ventilator; the oxygen of the air<br />

thus introduced combines in part with the <strong>antimony</strong>, forming the<br />

volatile oxide, and in part with the sulphur, forming sulphurous acid.<br />

The process of Hering(1883) was analogous to that of Herrenschmidt,<br />

the principal difference being that the roasting was effected in a<br />

reverberatory furnace.<br />

In 1883 Helmhacker first mentioned the use of cloth or sack for<br />

the condensation of the fine volatile oxide, in place of water, which is<br />

so destructive to the metallic lining of the reservoir.