DOMINO Panel Formwork - Peri

DOMINO Panel Formwork - Peri

DOMINO Panel Formwork - Peri

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

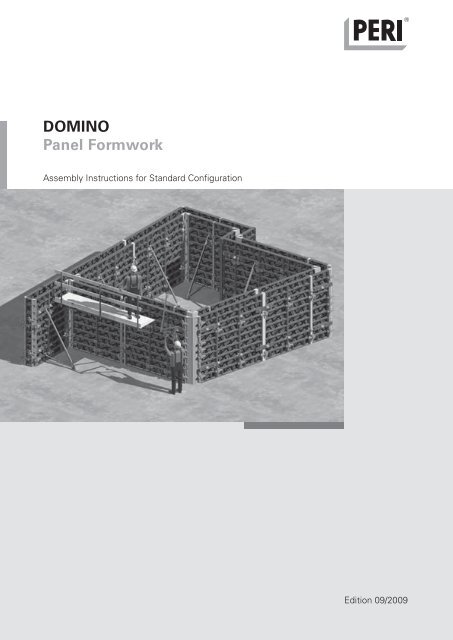

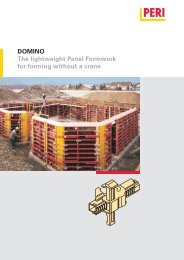

<strong>DOMINO</strong><br />

<strong>Panel</strong> <strong>Formwork</strong><br />

Assembly Instructions for Standard Configuration<br />

Edition 0�/2009

<strong>DOMINO</strong> <strong>Panel</strong> <strong>Formwork</strong><br />

Content<br />

Introduction<br />

Overview, main components 1<br />

Standard configuration 2<br />

Intended use 2<br />

Safety instructions 3<br />

General 3<br />

A General<br />

Basic assembly <strong>DOMINO</strong> 250<br />

A1 Storage and Transportation 4<br />

A2 Maintenance and Cleaning 5<br />

A3 Quick User Guide 6<br />

A4 <strong>DOMINO</strong> 250 <strong>Panel</strong>s 8<br />

A5 <strong>Panel</strong> Connections<br />

Alignment Coupler DRS 10<br />

Compensation Waler DAR 80 11<br />

Wedge Clamp DKS 11<br />

A6 Anchor Point 12<br />

A7 Push-Pull Props 13<br />

A8 Corners<br />

90° corners 14<br />

Articulated Corners 15<br />

135° corners 15<br />

A9 T-junctions<br />

90° T-junction 16<br />

Wall Connection 17<br />

A10 Wall Offset 18<br />

A11 Length Compensation 20<br />

A12 Stopend <strong>Formwork</strong><br />

With timber and filler plywood 21<br />

With Stopend <strong>Panel</strong> MT, MTF 22<br />

A13 Concreting Scaffold<br />

Scaffold Bracket DG 85 24<br />

Guardrails 26<br />

A14 Extensions 27<br />

A15 Foundations 28<br />

A16 <strong>DOMINO</strong> Alu <strong>Panel</strong>s 29<br />

Key<br />

B Basic assembly <strong>DOMINO</strong> 275<br />

B1 <strong>DOMINO</strong> 275 <strong>Panel</strong>s 30<br />

B2 Standard connection 31<br />

90° corners 31<br />

B3 Articulated Corners 32<br />

Stopend <strong>Formwork</strong> 32<br />

B4 Stopend <strong>Panel</strong> MTF 33<br />

B5 Extensions 34<br />

C Basic assembly <strong>DOMINO</strong> 300<br />

C1 <strong>DOMINO</strong> 300 <strong>Panel</strong>s 36<br />

C2 Standard connection 37<br />

90° corners 37<br />

C3 Articulated Corners 38<br />

C4 Stopend <strong>Formwork</strong> 39<br />

Extensions 39<br />

Components<br />

Components 40<br />

Important safety<br />

Instructions Hints Visual Check Tip<br />

Assembly Instructions for Standard Configuration

<strong>DOMINO</strong> <strong>Panel</strong> <strong>Formwork</strong><br />

Introduction<br />

Overview, main components<br />

B5<br />

B2<br />

B5<br />

B1<br />

A4<br />

B4<br />

A3 A1 A2<br />

A1 <strong>Panel</strong><br />

A2 <strong>Panel</strong> connection<br />

A3 Anchor<br />

A4 Push-Pull Props<br />

B1 Corners<br />

B2 T-junctions<br />

B3 Wall offset<br />

B4 Length compensation<br />

B5 Stopend formwork<br />

B6 Working and concreting scaffold<br />

B7 Height extension<br />

1 Assembly Instructions for Standard Configuration<br />

B7<br />

B3<br />

B6

<strong>DOMINO</strong> <strong>Panel</strong> <strong>Formwork</strong><br />

Introduction<br />

Standard configuration<br />

General<br />

The <strong>DOMINO</strong> wall formwork system<br />

consists of lightweight panel formwork<br />

for housing and civil engineering (foundations)<br />

projects with panels made of<br />

steel or aluminium.<br />

The basic equipment includes panel,<br />

corner and stopend elements as well as<br />

length compensation and scaffold<br />

brackets. For element connections, the<br />

alignment coupler or wedge clamp as<br />

well as the compensation waler are<br />

used, along with a range of additional<br />

parts required to carry out forming.<br />

Due to the integrated tie points, the<br />

panels can be used in both a vertical<br />

and horizontal position.<br />

The panels can be extended in 25 cm<br />

increments.<br />

Steel components are red powder-coated,<br />

aluminium elements are in yellow.<br />

Intended use<br />

1. PERI products are exclusively technical<br />

working materials which are intended<br />

for commercial use by technically<br />

competent users only.<br />

2. These assembly instructions serve as<br />

the basis for the project-related risk assessment<br />

and the instructions for the<br />

provision and use of the system by the<br />

contractor (user). However, they do not<br />

replace these.<br />

3. Only PERI original components may<br />

be used. The use of other products and<br />

spare parts represents a misapplication<br />

with associated safety risks.<br />

Steel panels h = 2.50 m<br />

– 3 panel heights and 4 panel widths<br />

– Permissible fresh concrete pressure:<br />

for concreting heights up to 2.50 m,<br />

withstands full hydrostatic pressure<br />

according to DIN 18202, Table 3, Line 7.<br />

For greater heights, a fresh concrete<br />

pressure of 60 kN/m² is permissible,<br />

Line 6.<br />

Aluminium panels h = 2.50 m<br />

– 2 panel heights and 2 panel widths<br />

– Permissible fresh concrete pressure:<br />

for concreting heights up to 2.50 m,<br />

withstands full hydrostatic pressure<br />

according to DIN 18202, Table 3, Line 6.<br />

For greater heights, a fresh concrete<br />

pressure of 50 kN/m² is permissible,<br />

Line 5.<br />

4. The components are to be inspected<br />

before each use to ensure that they are<br />

in perfect condition and function correctly.<br />

5. Changes to PERI components are<br />

not permissible and represent a misapplication<br />

with associated safety risks.<br />

6. Safety instructions and permissible<br />

loads must be observed at all times.<br />

7. Components provided by the contractor<br />

must conform with the characteristics<br />

required in these assembly instructions<br />

as well as all valid construction<br />

guidelines and standards.<br />

Steel panel h = 2.75 m<br />

– 3 panel heights and 4 panel widths<br />

– Permissible fresh concrete pressure:<br />

for concreting heights up to 2.75 m,<br />

withstands full hydrostatic pressure<br />

according to DIN 18202,Table 3, Line 6.<br />

Aluminium panel h = 2.75 m<br />

– 2 panel heights and 1 panel width<br />

– Permissible fresh concrete pressure:<br />

for concreting heights up to 2.75 m,<br />

withstands full hydrostatic pressure<br />

according to DIN 18202, Table 3, Line 6.<br />

Steel panel h = 3.00 m<br />

– 3 panel heights and 4 panel widths<br />

– Permissible fresh concrete pressure:<br />

60 kN/m² for concreting heights up to<br />

3.0 m according to DIN 18202,Table 3,<br />

Line 6.<br />

In particular, the following apply if nothing<br />

else is specified:<br />

– timber components: Strength Class<br />

C24 for Solid Wood EN 338.<br />

– scaffold tubes: galvanised steel tubing<br />

with minimum dimensions Ø 48.3<br />

x 3.2 mm according to EN 12811-<br />

1:2003 4.2.1.2.<br />

– scaffold tube couplings according to<br />

EN 74.<br />

8. Deviations from the standard configuration<br />

may only be carried out after a<br />

separate risk assessment has been<br />

done by the contractor (user). On this<br />

basis, appropriate measures for working<br />

safety along with the stability are to<br />

be implemented.<br />

2 Assembly Instructions for Standard Configuration

<strong>DOMINO</strong> <strong>Panel</strong> <strong>Formwork</strong><br />

Introduction<br />

Safety instructions<br />

General<br />

1. Deviations for the standard configuration<br />

and/or intended use present a potential<br />

safety risk.<br />

2. All country-specific laws, standards<br />

and other safety regulations are to be<br />

taken into account when our products<br />

are used.<br />

3. During unfavourable weather conditions,<br />

suitable precautions and measures<br />

are to be implemented in order to<br />

guarantee working safety and stability.<br />

4. The contractor (user) must ensure<br />

the stability throughout all phases of<br />

construction. He has to ensure and verify<br />

that all loads which occur are safely<br />

transferred.<br />

5. The contractor (user) has to provide<br />

safe working areas for site personnel<br />

which are to be reached through the<br />

provision of safe access means. Areas<br />

of risk must be cordoned off and clearly<br />

marked. Hatches and openings on accessible<br />

working areas must be kept<br />

closed during working operations.<br />

6. For better comprehensibility, detailed<br />

representations are partly incomplete.<br />

The safety installations which have possibly<br />

not been shown in these detailed<br />

descriptions must nevertheless be<br />

available.<br />

General<br />

Additional PERI product information<br />

– <strong>DOMINO</strong> poster<br />

– Instructions for Use for the <strong>DOMINO</strong><br />

Lifting Hook<br />

– Instructions for Use for pallets and<br />

stacking devices<br />

– PERI design tables<br />

Assembly Instructions for Standard Configuration<br />

Storage and transportation<br />

1. Do not drop the components.<br />

2. Store and transport components so<br />

that no unintentional change in their position<br />

is possible. Detach lifting gear<br />

from the lowered units only if these are<br />

in a stable position and no unimtentional<br />

change is possible.<br />

3. When moving, components are to be<br />

picked up and set down so that any unintentional<br />

toppling over, falling apart,<br />

slipping or rolling are avoided.<br />

4. Use only suitable load-carrying equipment<br />

to move the components as well<br />

as the designated load-bearing points.<br />

5, During lifting and moving procedures,<br />

ensure all loose parts are removed or<br />

secured.<br />

6. During the moving procedure, always<br />

use a guide rope.<br />

7. Move components only on clean, flat<br />

and sufficiently load-bearing surfaces.<br />

System-specific<br />

1. Retract components only when the<br />

concrete has sufficiently hardened and<br />

the person in charge has given the goahead<br />

for striking to take place.<br />

2. Anchoring is to take place only if the<br />

anchorage has sufficient concrete<br />

strength.<br />

The assemblies shown in these PERI<br />

assembly instructions are only examples<br />

which feature only one component<br />

size. They are valid accordingly for all<br />

component sizes contained in the<br />

standard configuration.<br />

3

<strong>DOMINO</strong> <strong>Panel</strong> <strong>Formwork</strong><br />

A1 Storage and Transportation<br />

Instructions for Use for PERI pallets<br />

and stacking devices must always be<br />

taken into consideration.<br />

Manually-created transportation<br />

units must be correctly stacked and<br />

secured.<br />

Transportation<br />

PERI pallets and stacking devices are<br />

suitable for lifting with a crane or forklift.<br />

They can also be moved with the PERI<br />

pallet lifting trolley.<br />

All pallets and stacking devices can be<br />

lifted using both the longitudinal and<br />

front sides.<br />

<strong>DOMINO</strong> Stacking Device<br />

<strong>Panel</strong>s of the same size are to be<br />

transported in stacks.<br />

(Fig. A1.01)<br />

Load-bearing capacity:<br />

500 kg/stacking device = 2.0 t/stack<br />

Number of panels per stack:<br />

2 – 5 <strong>DOMINO</strong> panels of the same size.<br />

Crane sling angle ≤ 45°<br />

4-sling lifting gear L = 3.0 m.<br />

(Fig. A1.02)<br />

Stacking height:<br />

3 stacks, one on top of each other.<br />

Transport of load<br />

Always attach the 4-sling lfting gear<br />

to the four points (1).<br />

(Fig. A1.01)<br />

4<br />

2<br />

1<br />

Fig. A1.01<br />

Fig. A1.02<br />

1<br />

Assembly<br />

1. Place the first panel with the formlining<br />

facing downwards on the rectangular<br />

tube (2). (Fig. A1.02)<br />

2. Insert the second and additional panels<br />

with the formlining facing upwards<br />

in the stacking devices.<br />

(Fig. A1.03)<br />

Fig. A1.03<br />

1<br />

Assembly Instructions for Standard Configuration<br />

1

<strong>DOMINO</strong> <strong>Panel</strong> <strong>Formwork</strong><br />

A2 Maintenance and Cleaning<br />

In order to maintain the value and<br />

operational readiness of the <strong>DOMINO</strong><br />

panel formwork over a long period of<br />

time, the formwork should be carefully<br />

handled at all times.<br />

Maintenance tips<br />

1. Concrete vibrator with rubber end<br />

cap reduces the risk of damage to the<br />

formlining.<br />

2. Spacers used for the reinforcement<br />

with large contact surfaces prevent impressions<br />

forming on the formlining.<br />

3. When placing heavy items on the<br />

formlining, use support timbers in order<br />

to prevent any impressions on and<br />

damage to the formlining surface.<br />

4. Spray the components with PERI Bio<br />

Clean before every use and clean the<br />

rear of the formwork with water immediately<br />

after concreting.<br />

(Fig. A2.01)<br />

5. Spray moving parts, if required, with<br />

PERI Bio Clean.<br />

6. For damage-free transportation, suitable<br />

PERI pallets and stacking devices<br />

are available.<br />

(Fig. A2.02)<br />

Due to the powder coating, cleaning requirements<br />

are kept to a minimum.<br />

Fig. A2.01<br />

Assembly Instructions for Standard Configuration<br />

Fig. A2.02<br />

5

<strong>DOMINO</strong> <strong>Panel</strong> <strong>Formwork</strong><br />

A3 Quick User Guide<br />

Procedures<br />

Primary <strong>Formwork</strong><br />

1. Horizontal assembly.<br />

(Fig. A3.01)<br />

2. Install push-pull props according to<br />

the valid width of influence.<br />

(Abb. A3.02)<br />

3. Transport to place of operations by<br />

crane.<br />

(Fig. A3.03)<br />

Secure panels to prevent tipping as<br />

well as withstanding wind forces.<br />

Release Lifting Hook only when the<br />

push-pull prop has been securely<br />

fixed in position.<br />

Closing formwork with concreting<br />

scaffold<br />

1. Mount brackets to the horizontallypositioned<br />

panel. (Fig. A3.04)<br />

2. Install decking and guardrails.<br />

(Fig. A3.05)<br />

3. Transport to place of operations by<br />

crane.<br />

4. Install anchors.<br />

Release Lifting Hook only after a top<br />

anchor has been installed.<br />

Forming from the external or internal<br />

corner in the direction of the compensation.<br />

6<br />

Fig. A3.01<br />

Fig. A3.03<br />

Fig. A3.04<br />

External corner Internal corner<br />

Fig. A3.02<br />

Fig. A3.05<br />

Assembly Instructions for Standard Configuration

<strong>DOMINO</strong> <strong>Panel</strong> <strong>Formwork</strong><br />

A3 Quick User Guide<br />

Concreting<br />

from safe and secure working scaffold.<br />

(Fig. A3.06)<br />

Striking and moving<br />

from the compensation to the corners.<br />

Concrete strength must be taken into<br />

account.<br />

Secure panels against tipping over<br />

and wind forces.<br />

Release Lifting Hook only when the<br />

push-pull prop has been securely<br />

fixed in position.<br />

Closing formwork<br />

1. Fix lifting hook and attach to crane.<br />

(Fig. A3.07)<br />

2. Remove anchors.<br />

3. Release panel connection.<br />

4. Move element, clean and transport<br />

to place of operations by crane.<br />

5. Connect panel, install anchors.<br />

6. Release crane lifting gear.<br />

Primary formwork<br />

1. Fix lifting hook and attach to crane.<br />

2. Release panel connection.<br />

3. Release push-pull prop anchoring.<br />

4. Move element, clean and transport<br />

to place of operations by crane.<br />

5. Connect panel.<br />

6. Install push-pull props.<br />

7. Release crane lifting gear.<br />

Cleaning<br />

with PERI Bio Clean and PERI spraying<br />

equipment. (Fig. A3.08)<br />

Working scaffold<br />

is not featured<br />

here.<br />

Assembly Instructions for Standard Configuration<br />

Fig. A3.06<br />

Fig. A3.08<br />

Fig. A3.07<br />

7

<strong>DOMINO</strong> <strong>Panel</strong> <strong>Formwork</strong><br />

A4 <strong>DOMINO</strong> 250 <strong>Panel</strong>s<br />

Height [cm]<br />

8<br />

250<br />

125<br />

75<br />

100 75 50<br />

Width [cm]<br />

25 75<br />

DGE<br />

S) A) S) A) S) S) S) A) N) A) A) A)<br />

S) A)<br />

S) A)<br />

Key<br />

S) <strong>Panel</strong>s with steel frames (red powder-coated)<br />

A) <strong>Panel</strong>s with aluminium frames (yellow powder-coated)<br />

N) Standard elements or multi-purpose panels<br />

H) Timber panels<br />

S)<br />

S)<br />

S)<br />

S)<br />

S)<br />

S)<br />

S) A) N)<br />

S) N)<br />

A)<br />

A)<br />

DAW DWD DPA<br />

Assembly Instructions for Standard Configuration<br />

A)<br />

A)<br />

A)<br />

A)<br />

H)<br />

H)

<strong>DOMINO</strong> <strong>Panel</strong> <strong>Formwork</strong><br />

A4 <strong>DOMINO</strong> 250 <strong>Panel</strong>s<br />

<strong>Panel</strong> 250 x 100<br />

10.4<br />

10.5<br />

10.2<br />

(10) <strong>DOMINO</strong> panel<br />

(10.1) Anchor point with tubular rivet<br />

(10.2) <strong>Panel</strong> strut<br />

(10.3) Connecting possibilities for<br />

accessories<br />

(10.4) Transportation holes<br />

(10.5) Openings for moving by hand<br />

(10.6) Frame<br />

(10.7) Formlining<br />

Assembly Instructions for Standard Configuration<br />

10<br />

10.3<br />

10.3<br />

10.6<br />

10.7<br />

10.1<br />

10.3<br />

10.3<br />

10.1<br />

9

<strong>DOMINO</strong> <strong>Panel</strong> <strong>Formwork</strong><br />

A5 <strong>Panel</strong> Connections<br />

Alignment Coupler DRS<br />

Areas of use:<br />

– standard connection<br />

– external corner, internal corner<br />

– obtuse and acute-angled corners<br />

– stopend formwork<br />

– filler timber<br />

– extensions<br />

Number required<br />

2 alignment couplers DRS (20) for<br />

h = 2.50 m on standard connections.<br />

(Fig. A5.01)<br />

Assembly<br />

1. Place wedge (20.1) in upper end position.<br />

2. Open sliding part (20.2).<br />

(Fig. A5.02).<br />

3. Attach Alignment Coupler (20) to<br />

panel strut (10.2).<br />

4. Close sliding part. Continuous adjustment<br />

using the keyway (20.3) possible.<br />

5. Secure wedge. (Fig. A5.03)<br />

The Alignment Coupler is now securely<br />

in position.<br />

If the wedge head (20.4) is up against<br />

the sliding part, there is no clamping effect!<br />

If so, release the wedge, re-position<br />

the sliding part and secure again with<br />

the hammer.<br />

When securing the wedge, the following<br />

effects occur due to the angle of<br />

the frame profile:<br />

1. <strong>Panel</strong>s are flush.<br />

2. <strong>Panel</strong>s are aligned.<br />

3. <strong>Panel</strong>s are tightly connected.<br />

(Fig. A5.03.1)<br />

10<br />

20.3<br />

Fig. A5.02<br />

Fig. A5.03<br />

20<br />

20.2<br />

20.1<br />

20.4<br />

Fig. A5.01<br />

Fig. A5.03.1<br />

3<br />

Assembly Instructions for Standard Configuration<br />

1<br />

20<br />

2

<strong>DOMINO</strong> <strong>Panel</strong> <strong>Formwork</strong><br />

A5 <strong>Panel</strong> Connections<br />

Compensation Waler DAR 80<br />

The Compensation Waler DAR 80 (21)<br />

is used to brace and align panel connections<br />

as well as for transferring forces.<br />

Areas of use:<br />

– length compensation<br />

– corners with double Wall Thickness<br />

Compensator WDA<br />

– acute and obtuse-angled corners<br />

– wall offsets<br />

– stopend formwork<br />

– extensions at great heights<br />

Assembly<br />

1. Insert the hooks into the connecting<br />

holes 10.3 of the panel.<br />

2. Secure wedge.<br />

(Fig. A5.04)<br />

Wedge Clamp DKS<br />

For standard panel joints in the area of<br />

the foundations.<br />

(Fig. A5.05)<br />

Fig. A5.05<br />

Assembly Instructions for Standard Configuration<br />

21<br />

Fig. A5.04<br />

10.3<br />

11

<strong>DOMINO</strong> <strong>Panel</strong> <strong>Formwork</strong><br />

A6 Anchor Point<br />

Anchor System DW 15<br />

Permissible load of the tie rod according<br />

to DIN 18216 is 90 kN.<br />

Components for DW 15<br />

– Tie Rod (30)<br />

– Spacer Tube (31)<br />

– Cone (32)<br />

– Wingnut Pivot Plate (33)<br />

(Fig. A6.01)<br />

Miscellaneous<br />

– Tie Rod Wrench (34) for one-man anchor<br />

point operations from one side<br />

– Plug (35) for sealing tie holes which<br />

are not required.<br />

(Fig. A6.02)<br />

Application<br />

– Use only the required number of ties.<br />

Seal tie holes which are not required.<br />

– Do not exceed permissible tie loads.<br />

– Comply with rate of rise.<br />

– With the use of articulated corners as<br />

90° internal corners, only the outer<br />

drilled holes may be used for anchoring<br />

if using Wingnut Pivot Plates.<br />

(Fig. A6.03)<br />

– If using compensation walers, both<br />

drilled holes can be used for anchoring<br />

e.g. oblique angles.<br />

(Fig. A6.03)<br />

12<br />

30<br />

Fig. A6.01<br />

Fig. A6.02<br />

33 31<br />

34<br />

Fig. A6.03<br />

32<br />

Detail<br />

35<br />

Ø 20 mm<br />

Outer drilled holes<br />

Assembly Instructions for Standard Configuration

<strong>DOMINO</strong> <strong>Panel</strong> <strong>Formwork</strong><br />

A7 Push-Pull Props<br />

Push-Pull Prop Connector<br />

DRA<br />

Assembly<br />

Push-Pull Props and Kicker Braces are<br />

attached to the panels by means of the<br />

Push-Pull Prop Connector DRA (41).<br />

Connections are only possible using the<br />

horizontal panel struts.<br />

(Fig. A7.01)<br />

1. Place the Wedge Closing Device (42)<br />

in a vertical position.<br />

2. Insert the Push-Pull Prop Connector<br />

from below through the connecting<br />

hole.<br />

3. Turn the Wedge Closing Device to a<br />

horizontal position and secure.<br />

Push-Pull Props and Kicker<br />

Braces<br />

1. Attach Push-Pull Prop (40) or Kicker<br />

Brace to the connecting plate (43) using<br />

Pins and Cotter Pins (44).<br />

(Fig. A7.02)<br />

2. Fix base plate, e.g. with PERI Multi<br />

Monti 20 x 130 (45).<br />

(Fig. A7.03)<br />

Permissible push-pull prop spacings<br />

<strong>Formwork</strong> height h<br />

[m]<br />

Max. width of influence<br />

[m]<br />

Actual prop load FRS at maximum<br />

prop spacing<br />

Actual kicker brace load FAV [kN] at<br />

max. prop spacing<br />

distance of base plate [m] from<br />

x =<br />

rear edge of formwork<br />

distance of top connection point<br />

y =<br />

[m] from top of formwork<br />

41<br />

43<br />

2.50 2.75 3.00 4.00 5.00<br />

2.85 2.30 1.82 1.41 1.12<br />

5.0 5.0 5.0 5.0 5.0<br />

2.0 1.5 1.0 1.2 1.1<br />

1.2 1.2 1.2 1.6 2.0<br />

0.5 0.8 1.0 1.2 1.5<br />

Assembly Instructions for Standard Configuration<br />

44<br />

42<br />

41<br />

40<br />

Fig. A7.01 Fig. A7.02<br />

h < 8 m = 0.5 kN/m2 8 m < h < 20 m = 0.8 kN/m2 For the given widths of influence, a maximum force of 11.3 kN<br />

is transferred into the building at the foot of the push-pull<br />

prop.<br />

Perm. F (all directions) Hilti HKD M20 x 80 (B25) 5.8 kN.<br />

Recommended F (all directions) Anchor Bolt MMS 20x130<br />

for concrete<br />

with ß w > 20 N/mm2 11.3 kN<br />

Wind Loads:<br />

If the dynamic pressure deviates from 0.5 kN/m², the<br />

widths of influence can be changed proportionately from<br />

the existing dynamic pressure to 0.5 kN/m².<br />

40<br />

Fig. A7.03<br />

h<br />

43<br />

kN/m 2<br />

0.5<br />

y<br />

FAV<br />

x<br />

FRS<br />

60°<br />

45<br />

13

<strong>DOMINO</strong> <strong>Panel</strong> <strong>Formwork</strong><br />

A8 Corners<br />

90° corners<br />

Wall thicknesses from 20 cm to 36.5 cm<br />

can be continuously formed.<br />

(Fig. A8.01)<br />

– wall thickness 25 cm is without any<br />

adjustment<br />

– for wall thicknesses < 25 cm adjustment<br />

inside<br />

– for wall thicknesses > 25 cm adjustment<br />

outside<br />

Adjustments are carried out by means<br />

of the Wall Thickness Compensator<br />

DWD 5 (18) or timber provided by the<br />

contractor (50).<br />

External corner<br />

Consisting of:<br />

– <strong>Panel</strong> ...x 50 (11)<br />

– Outside Corner Angle DAW (12)<br />

– 2 x Alignment Coupler DRS (20) per<br />

side<br />

(Fig. A8.02)<br />

Internal corner<br />

Consisting of:<br />

– Articulated Corner DGE (13) with Corner<br />

Locking 90° (13.1)<br />

– 2 x Alignment Coupler DRS (20) per<br />

side<br />

(Fig. A8.03)<br />

For the number of Alignment Couplers<br />

required for other panel heights: see<br />

the <strong>DOMINO</strong> poster.<br />

14<br />

50<br />

18<br />

DWD 5<br />

50<br />

Fig. A8.01<br />

Fig. A8.02<br />

20<br />

50<br />

50<br />

30 cm<br />

18<br />

DWD 5<br />

12 11<br />

20<br />

50<br />

18<br />

DWD 5<br />

50<br />

18<br />

2 DWD 5<br />

50<br />

50<br />

24<br />

50<br />

50<br />

35 cm<br />

50<br />

Filler timber 1 cm<br />

18<br />

2 DWD 5<br />

13<br />

13.1<br />

Assembly Instructions for Standard Configuration<br />

50<br />

18<br />

2 DWD 5<br />

Filler timber 1.5 cm<br />

20<br />

50<br />

50<br />

90°<br />

50<br />

25<br />

50<br />

36.5 cm<br />

50<br />

Timber 11.5 cm<br />

50<br />

13.1<br />

Fig. A8.03

<strong>DOMINO</strong> <strong>Panel</strong> <strong>Formwork</strong><br />

A8 Corners<br />

Articulated Corners<br />

For oblique angles of 75° and more.<br />

(Fig. A8.04)<br />

DRS Alignment Couplers are to be installed<br />

in a bottom to top direction for<br />

both external and internal corners.<br />

For the number of Alignment Couplers<br />

required for other panel heights: see<br />

the <strong>DOMINO</strong> poster.<br />

External corner<br />

Consisting of:<br />

5 x Alignment Coupler DRS (20) and<br />

2 x Compensation Waler DAR 80 (23)<br />

for h = 2.50 m. (Fig. A8.04)<br />

Internal corner<br />

Consisting of:<br />

4 x Alignment Coupler DRS (20) for<br />

h = 2.50 m. (Fig. A8.06)<br />

135° corners<br />

For 135° corners, the Positioning Pin<br />

135° (13.1) is used on both the inside<br />

and outside.<br />

(Fig. A8.05)<br />

Assembly of the Locking Pin<br />

1. Remove Corner Locking 90°.<br />

2. Install Positioning Pin 135° with Bolt.<br />

Filler areas (x)<br />

Angle Wall thickness<br />

[cm]<br />

20 25 30 35 36<br />

165° 2.7 3.4 4.1 4.7 4.8<br />

150° 5.6 6.9 8.3 9.6 9.9<br />

135° 8.6 10.7 12.8 14.8 15.2<br />

120° 12 14.9 17.8 20.7 21.2<br />

105° 16 19.8 23.6 27.5 28.2<br />

75° 27.1 33.6 40.1 46.7 48<br />

Fig. A8.04<br />

Fig. A8.06<br />

Assembly Instructions for Standard Configuration<br />

x<br />

13<br />

75<br />

min. 75°<br />

max. 165°<br />

20<br />

75<br />

23<br />

13.1 outside<br />

13.1 inside<br />

x<br />

135°<br />

135°<br />

Fig. A8.05<br />

15

<strong>DOMINO</strong> <strong>Panel</strong> <strong>Formwork</strong><br />

A9 T-junctions<br />

90° T-junctions<br />

Wall thicknesses from 15 cm to 35 cm<br />

can be continuously formed.<br />

(Fig. A9.01)<br />

– wall thickness 25 cm without any adjustment<br />

– for wall thicknesses < 25 cm adjustment<br />

inside<br />

– for wall thicknesses > 25 cm adjustment<br />

outside<br />

Adjustments are carried out by means<br />

of the Wall Thickness Compensator<br />

DWD 5 (18) or timber provided by the<br />

contractor (50).<br />

Assembly<br />

– forming the T-junction with the Articulated<br />

Corner DGE (13)<br />

– form the straight wall section on the<br />

opposite side with <strong>Panel</strong> D 75 (15).<br />

Two compensators (DWD) are required:<br />

install one DWD right and left of the<br />

<strong>Panel</strong> D 75 respectively.<br />

Pilaster<br />

For the arrangement and number of the<br />

horizontal Compensation Walers DAR<br />

80 (24) and Frame Spanner (55):<br />

see Stopend <strong>Formwork</strong> with Timber.<br />

(Fig. A9.02)<br />

16<br />

Fig. A9.01<br />

Fig. A9.02<br />

13<br />

24<br />

15<br />

20<br />

75<br />

25<br />

75<br />

13<br />

55<br />

18<br />

35 36.5<br />

75 75 cm<br />

75 cm<br />

15<br />

Assembly Instructions for Standard Configuration<br />

24<br />

13 13<br />

13 13<br />

13<br />

13<br />

13<br />

15<br />

15<br />

18<br />

13<br />

13<br />

15<br />

15<br />

75<br />

30<br />

75<br />

50<br />

Filler timber 1 cm<br />

13<br />

18<br />

50<br />

Timber 11.5 cm

<strong>DOMINO</strong> <strong>Panel</strong> <strong>Formwork</strong><br />

A9 Wall Connection<br />

Obtuse wall connection<br />

With <strong>DOMINO</strong> <strong>Panel</strong> and Cam Nut<br />

DW 15 (19).<br />

(Fig. A9.03)<br />

With Multi-Purpose <strong>Panel</strong> DM ... x75.<br />

(Fig. A9.04)<br />

With Wall Thickness Compensator<br />

DWD (18) or timber supplied by contractor.<br />

(Fig. A9.05)<br />

Fig. A9.03<br />

Fig. A9.04<br />

Fig. A9.05<br />

Assembly Instructions for Standard Configuration<br />

19<br />

DM 75<br />

DM 75<br />

100 cm<br />

100 cm<br />

18<br />

100 cm<br />

100 cm<br />

100 cm<br />

100 cm<br />

100 cm<br />

100 cm<br />

100 cm<br />

100 cm<br />

17

<strong>DOMINO</strong> <strong>Panel</strong> <strong>Formwork</strong><br />

A10 Wall Offset<br />

Wall offset ≤ 17 cm<br />

By moving the panel laterally.<br />

Consisting of:<br />

– Compensation Waler DAR 80 (21)<br />

– Hook Tie DW 15/400 (29)<br />

– compensation provided by contractor<br />

(50)<br />

– plywood filler at the front (51)<br />

– additional Wedge Clamp DKS (20) for<br />

> 12 cm wall offsets<br />

(Fig. A10.01)<br />

Wall offset 17 – 83 cm<br />

Consisting of:<br />

– Multi-Purpose <strong>Panel</strong> DM 75 (10) (3 cm<br />

increments)<br />

– Articulated Corner DGE (13) internally<br />

and externally<br />

– Compensation Waler DAR 80 (21)<br />

– Stopend Tie DSA (25)<br />

– compensation provided by contractor<br />

(50)<br />

(Fig. A10.02)<br />

Wall offset 25 – 37 cm<br />

Consisting of:<br />

– Articulated Corner DGE (13) internally<br />

and externally<br />

– Outside Corner Angle DAW (12)<br />

– Compensation Waler DAR 80 (21)<br />

– compensation provided by contractor<br />

(50) (maximum 12 cm)<br />

(Fig. A10.03)<br />

Locating board facilitates the positioning<br />

of the formwork panel.<br />

18<br />

Fig. A10.01<br />

Fig. A10.02<br />

Fig. A10.3<br />

13<br />

50 29 20 21<br />

50<br />

12<br />

25<br />

13<br />

≤ 17<br />

21 20<br />

10<br />

≤ 83 cm<br />

25 – 37<br />

21<br />

21<br />

≥ 17<br />

12<br />

51<br />

13<br />

50<br />

29 50<br />

21<br />

10<br />

21<br />

13<br />

25<br />

Assembly Instructions for Standard Configuration

<strong>DOMINO</strong> <strong>Panel</strong> <strong>Formwork</strong><br />

A10 Wall Offset<br />

Height offset<br />

For height offsets: depending on the<br />

offset itself, Alignment Couplers DRS<br />

(20) are installed alternately on the<br />

frame struts of the right and left panels.<br />

(Fig. A10.04)<br />

Fig. A10.04<br />

Assembly Instructions for Standard Configuration<br />

20<br />

20<br />

19

<strong>DOMINO</strong> <strong>Panel</strong> <strong>Formwork</strong><br />

A11 Length Compensation<br />

With timber ≤ 12 cm provided<br />

by the contractor<br />

Length compensation takes place using<br />

timber which has been cut to size (50).<br />

(Fig. A11.01)<br />

– Timber ≤ 10 cm with Alignment Coupler<br />

DRS.<br />

– Timber ≤ 12 cm with Alignment Coupler<br />

DRS and Compensation Waler<br />

DAR 80.<br />

– With compensations > 2.5 cm, anchor<br />

in middle of timber.<br />

– Alignment Couplers DRS (20) are to<br />

arranged as for standard element<br />

joints.<br />

– The Wingnut Pivot Plate DW 15 must<br />

overlap the frame of the adjoining<br />

panel by at least 1 cm<br />

(for timber ≤ 10 cm).<br />

With Filler Support DPA for<br />

compensations up to 30 cm<br />

Consisting of:<br />

– 2 x Filler Support DPA (53)<br />

– plywood filler 21 mm (51)<br />

(Fig. A11.02)<br />

Anchoring must be carried out so that<br />

anchor forces are transferred through<br />

the centre of the PERI Compensation<br />

Waler DAR 80 (21) to the adjacent panels.<br />

20<br />

20<br />

53<br />

max. 10 cm<br />

50<br />

51<br />

Fig. A11.01<br />

Fig. A11.02<br />

21<br />

max. 30 cm<br />

Assembly Instructions for Standard Configuration

<strong>DOMINO</strong> <strong>Panel</strong> <strong>Formwork</strong><br />

A12 Stopend <strong>Formwork</strong><br />

With timber and filler plywood<br />

For wall thicknesses up to 36.5 cm.<br />

Consisting of:<br />

– 3 x Compensation Waler DAR 80 (24)<br />

– 6 x Stopend Tie DSA (25) with Wingnut<br />

Pivot Plate<br />

– 6 x Top Tie Bracket DAH (55) with<br />

Frame Spanner DW 15<br />

(Fig. A12.01)<br />

The fresh concrete pressure from the<br />

Stopend <strong>Formwork</strong> is transferred by<br />

means of the Stopend Tie and Compensation<br />

Waler DAR 80 to the <strong>DOMINO</strong><br />

panels.<br />

24<br />

Fig. A12.01<br />

Assembly Instructions for Standard Configuration<br />

25<br />

55<br />

21

<strong>DOMINO</strong> <strong>Panel</strong> <strong>Formwork</strong><br />

A12 Stopend <strong>Formwork</strong><br />

Stopend panel reinforcement<br />

with and without water<br />

bar<br />

H = 2.50 m and 1.25 m<br />

Consisting of:<br />

– 2 x Outside Pieces AT 3 (56) for approx.<br />

2.5 cm concrete cover or 2 x AT 5 for<br />

approx. 5 cm concrete covering<br />

– 1 x Centre Piece MTF (57)<br />

(Fig. A12.02)<br />

The rubber lip (56.1) allows a continuous<br />

reinforcement thickness of 16 mm.<br />

Assembly without water bar<br />

1. Position primary formwork.<br />

2. Attach Outside Piece AT (56) by<br />

means of Alignment Coupler DRS (20).<br />

3. Install first layer of reinforcement.<br />

4. Place Centre Piece MT (57) in position.<br />

5. Install second layer of reinforcement.<br />

6. Position closing formwork.<br />

7. Install second Outside Piece AT (56)<br />

in Centre Piece MT.<br />

8. Fix with Alignment Coupler DRS (20).<br />

(Fig. A12.03)<br />

22<br />

56.1<br />

Fig. A12.02<br />

20<br />

Fig. A12.03<br />

57 MTF<br />

56 AT<br />

56 57<br />

56.1<br />

16 mm<br />

56 57<br />

MTF<br />

AT<br />

16 mm<br />

DM 75<br />

Concrete cover c:<br />

d - b<br />

c = - Ø<br />

2<br />

c<br />

c<br />

b<br />

c<br />

c<br />

b<br />

DM 75<br />

Reinforcement<br />

d<br />

d<br />

Assembly Instructions for Standard Configuration

<strong>DOMINO</strong> <strong>Panel</strong> <strong>Formwork</strong><br />

A12 Stopend <strong>Formwork</strong><br />

Assembly with water bar<br />

1. Position primary formwork.<br />

2. Attach Outside Piece AT (56) by<br />

means of Alignment Coupler DRS (20).<br />

3. Install first layer of reinforcement.<br />

4. Place Centre Piece MTF (58) in position<br />

and install water bar.<br />

5. Install second layer of reinforcement.<br />

6. Position closing formwork.<br />

7. Install second Outside Piece AT (56)<br />

in Centre Piece MTF.<br />

8. Fix with Alignment Coupler DRS (20).<br />

(Fig. A12.04)<br />

Stopend panel with water<br />

bar<br />

Consisting of:<br />

– 2 x Outside Pieces AT (56)<br />

– 1 x Centre Piece MTF (57)<br />

– 2 x filler plates (51) supplied by the<br />

contractor<br />

56<br />

57<br />

20<br />

51<br />

51<br />

Fig. A12.04<br />

H = 2,50 m<br />

AT 250x3<br />

AT 250x5<br />

H = 1,25 m<br />

AT 125x3<br />

AT 125x5<br />

Assembly Instructions for Standard Configuration<br />

MT 250x20<br />

MT 250x24/25<br />

MT 250x30<br />

MT 250x35/36<br />

MTF 250x20<br />

MTF 250x24/25<br />

MTF 250x30<br />

MTF 250x35/36<br />

MT 125x20<br />

MT 125x24/25<br />

MT 125x30<br />

MT 125x35/36<br />

MTF 125x20<br />

MTF 125x24/25<br />

MTF 125x30<br />

MTF 125x35/36<br />

Wall thickness d [cm]<br />

b<br />

Concrete cover approx. 25 mm Concrete cove approx. 50 mm<br />

[mm] 20 24/25 30 35/36 24/25 30 35/36 40<br />

– 2 2 2 2<br />

– 2 2 2 2<br />

without water bar without water bar<br />

118 1 1<br />

158 1 1<br />

218 1 1<br />

268 1 1<br />

with water bar<br />

with water bar<br />

118 1 1<br />

158 1 1<br />

218 1 1<br />

268 1 1<br />

– 2 2 2 2<br />

– 2 2 2 2<br />

without water bar without water bar<br />

118 1 1<br />

158 1 1<br />

218 1 1<br />

268 1 1<br />

with water bar<br />

with water bar<br />

118 1 1<br />

158 1 1<br />

218 1 1<br />

268 1 1<br />

23

<strong>DOMINO</strong> <strong>Panel</strong> <strong>Formwork</strong><br />

A13 Concreting Scaffold<br />

Scaffold Bracket DG 85<br />

Concreting scaffold is mounted on the<br />

Domino formwork with the Scaffold<br />

Bracket DG 85.<br />

(Fig. A13.01)<br />

Consisting of:<br />

– Scaffold Bracket DG 85 (63)<br />

– Handrail Post HSGP (66)<br />

Permissible load 1.5 kN/m²<br />

Secure planking.<br />

Decking components and guardrails<br />

must be mounted securely in position<br />

at all times.<br />

With extended formwork units, the<br />

working scaffold is mounted as part of<br />

the pre-assembly process.<br />

Permissible bracket spacing in [m]<br />

for scaffolding platform consisting of<br />

wooden planks or boards<br />

Table 8, DIN 4420 Part 1.<br />

Scaffold group Board or plank width Board or plank thickness<br />

24<br />

1, 2, 3<br />

63<br />

3.0 cm 3.5 cm 4.0 cm 4.5 cm 5.0 cm<br />

20 cm 1.25 1.50 1.75 2.25 2.50<br />

24 / 28 cm<br />

1.25 1.75 2.25 2.50 2.75<br />

66<br />

m<br />

2.50<br />

Fig. A13.01<br />

Assembly Instructions for Standard Configuration<br />

m<br />

> 2.00

<strong>DOMINO</strong> <strong>Panel</strong> <strong>Formwork</strong><br />

A13 Concreting Scaffold<br />

Scaffold Bracket DG 85<br />

Assembly<br />

1. Insert Handrail Post HSGP.<br />

2. Slide back fastening bolts (63.1).<br />

3. Hook in Scaffold Brackets (63) in the<br />

connecting holes of the panel and secure<br />

with the fastening bolts.<br />

(Fig. A13.02)<br />

It is possible to use the horizontal panel<br />

struts.<br />

Visual control of the suspension equipment!<br />

4. Install decking planks from below<br />

across the complete bracket width and<br />

then secure.<br />

5. Install guardrails and secure with<br />

nails.<br />

6. Mount end guardrails, e.g. End Handrail<br />

Frame 55 (64).<br />

(Fig. A13.03)<br />

Fig. A13.02<br />

Fig. A13.03<br />

Assembly Instructions for Standard Configuration<br />

64<br />

63<br />

max. prop spacing 2.0 m<br />

max. width of influence 2.0 m<br />

63.1<br />

25

<strong>DOMINO</strong> <strong>Panel</strong> <strong>Formwork</strong><br />

A13 Concreting Scaffold<br />

Guardrails<br />

Consisting of:<br />

– Handrail Post Holder <strong>DOMINO</strong> (65)<br />

– Handrail Post HSGP (66)<br />

(Fig. A13.04)<br />

With a fall-height > 3.0 m, guardrails<br />

are required on the opposite side of the<br />

concreting scaffiold.<br />

Assembly is carried out horizontally. In<br />

cases of vertical assembly use e.g. a<br />

mobile scaffold.<br />

Secure boards with nails!<br />

Assembly<br />

1. Slide back fastening bolts (63.1) and<br />

hook in Handrail Post Holder <strong>DOMINO</strong><br />

(65) in the connecting holes of the panel.<br />

2. Secure with Cotter Pins.<br />

3. Insert Handrail Post HSGP (66).<br />

4. Install guardrails and secure with<br />

nails.<br />

(Fig. A13.05)<br />

When erecting, make sure that the<br />

guardrails are not damaged by the lifting<br />

gear.<br />

Assembly is only possible on vertical<br />

struts.<br />

With extended formwork units, the<br />

guardrails are mounted as part of the<br />

pre-assembly process.<br />

Dismantling<br />

Do not lay the formwork panel on the<br />

Handrail Post Holder <strong>DOMINO</strong> (65).<br />

26<br />

Fig. A13.04<br />

Fig. A13.05<br />

65<br />

66<br />

max. prop spacing 2.0 m<br />

max. width of influence 2.0 m<br />

63.1<br />

Assembly Instructions for Standard Configuration

<strong>DOMINO</strong> <strong>Panel</strong> <strong>Formwork</strong><br />

A14 Extensions<br />

Extension guidelines for<br />

horizontal pre-assembly up<br />

to h = 5.00 m<br />

Do not exceed permissible load-bearing<br />

capacity of the <strong>DOMINO</strong> Lifting<br />

Hook (500 kg) and crane capacity!<br />

Extension possibilities, number and arrangement<br />

of DRS Alignment Couplers,<br />

DAR 80 Compensation Walers and<br />

formwork anchors are featured on the<br />

<strong>DOMINO</strong> poster.<br />

<strong>Panel</strong> connections:<br />

With one or more horizontal and vertical<br />

panel joints, always use the DRS<br />

Alignment Coupler (20).<br />

(Fig. A14.01 - A14.05)<br />

Pre-assemble extension units horizontally<br />

with the formlining face down.<br />

Place timbers or planks in position as<br />

support. The assembly area must be<br />

flat.<br />

Erection with the crane.<br />

(Fig. A14.06)<br />

Fig. A14.06<br />

Fig.<br />

A14.01<br />

Assembly Instructions for Standard Configuration<br />

25 cm<br />

50 cm<br />

75 cm<br />

50 cm 100 cm<br />

100 cm<br />

20<br />

Fig.<br />

A14.02<br />

Fig.<br />

A14.03<br />

m<br />

≤ 5.0<br />

m<br />

3.75<br />

1.25 m<br />

2.50 m<br />

m<br />

2.50<br />

Fig. A14.04<br />

Fig. A14.05<br />

27

<strong>DOMINO</strong> <strong>Panel</strong> <strong>Formwork</strong><br />

A15 Foundations<br />

Foundation <strong>Formwork</strong><br />

All <strong>DOMINO</strong> panels are suitable for<br />

shuttering foundations.<br />

In addition, <strong>DOMINO</strong> panels with h = 125<br />

have inset tie points and can be used<br />

horizontally without any problems.<br />

(Fig. A15.01)<br />

Foundation Tie Clamp<br />

If the bottom tie positions are missing<br />

in the strip and individual foundations,<br />

the Foundation Tie Spanner DLS together<br />

with the Perforated Foundation Tie<br />

are used.<br />

Required Perforated Foundation Tie<br />

length:<br />

Foundation width + 50 cm.<br />

Assembly<br />

1. Position the panel on the Perforated<br />

Foundation Tie (86).<br />

2. Fix the Foundation Tie Spanner (85)<br />

in the lowest connecting hole by means<br />

of bolts (85.1).<br />

3. Attach the Perforated Foundation Tie<br />

in the tensioning lever (85.2).<br />

4. Tension with ratchet, SW 14. Permissible<br />

tension force: 16 kN (for foundation<br />

formwork).<br />

(Fig. A15.02)<br />

28<br />

Fig. A15.01<br />

85<br />

85.1<br />

85.2<br />

Fig. A15.02<br />

SW 14<br />

86<br />

2.50 m<br />

1.25 m<br />

max.<br />

86<br />

11.7<br />

85<br />

approx.<br />

25 cm<br />

Assembly Instructions for Standard Configuration

<strong>DOMINO</strong> <strong>Panel</strong> <strong>Formwork</strong><br />

A16 <strong>DOMINO</strong> Alu <strong>Panel</strong>s<br />

<strong>Panel</strong>s<br />

When using <strong>DOMINO</strong> Alu elements,<br />

the same formwork guidelines apply as<br />

for the <strong>DOMINO</strong> 250 Steel.<br />

Available panel widths for h = 2.5 m<br />

and 1.25 m:<br />

100 / 75 / DMA 75 cm.<br />

(Fig. A16.01 - A16.06)<br />

– It can be combined with <strong>DOMINO</strong><br />

Steel.<br />

– For extensions in combination with<br />

steel elements, the aluminium panels<br />

are always to be installed at the top.<br />

Assembly Instructions for Standard Configuration<br />

2.50 m<br />

1.25 m<br />

Fig. A16.01<br />

Fig. A16.04<br />

100 cm<br />

75 cm<br />

DMA 75<br />

Fig. A16.02<br />

Fig. A16.05<br />

Fig. A16.03<br />

Fig. A16.06<br />

29

<strong>DOMINO</strong> <strong>Panel</strong> <strong>Formwork</strong><br />

B1 <strong>DOMINO</strong> 275 <strong>Panel</strong>s<br />

Height [cm]<br />

Key<br />

S) <strong>Panel</strong>s with steel frames<br />

(red powder-coated)<br />

A) <strong>Panel</strong>s with aluminium frames<br />

(yellow powder-coated)<br />

N) Standard elements or multi-purpose panels<br />

H) Timber panels<br />

30<br />

275<br />

125<br />

75<br />

100 75 50<br />

Width [cm]<br />

25 75<br />

S) A)<br />

S) S) A) S)<br />

S)<br />

S) A)<br />

S)<br />

S)<br />

S)<br />

Alu panels<br />

When using the Alu panels, the same<br />

formwork guidelines apply as for the<br />

H = 250 connections and extensions.<br />

S)<br />

S)<br />

S)<br />

S) A) N) A) A) A)<br />

S) A) N)<br />

S) N)<br />

DGE DAW DWD DPA<br />

A)<br />

A)<br />

Assembly Instructions for Standard Configuration<br />

A)<br />

A)<br />

A)<br />

A)<br />

H)<br />

H)

<strong>DOMINO</strong> <strong>Panel</strong> <strong>Formwork</strong><br />

B2 <strong>DOMINO</strong> 275<br />

Standard joint<br />

2 x Alignment Coupler DRS (20).<br />

(Fig. B2.01)<br />

External Corner 90°<br />

3 x Alignment Coupler DRS per side.<br />

(Fig. B2.02)<br />

Internal Corner 90°<br />

2 x Alignment Coupler DRS per side.<br />

(Fig. B2.03)<br />

Assembly Instructions for Standard Configuration<br />

20<br />

Fig. B2.02<br />

Fig. B2.03<br />

Fig. B2.01<br />

31

<strong>DOMINO</strong> <strong>Panel</strong> <strong>Formwork</strong><br />

B3 <strong>DOMINO</strong> 275<br />

Internal articulated corner<br />

4 x Alignment Coupler DRS per side.<br />

For 135° corners, additional 2 x Positioning<br />

Pins 135° inside (13.1).<br />

(Fig. B3.01)<br />

External articulated corner<br />

5 x Alignment Coupler DRS per side<br />

and 2 x Compensation Waler DAR 80<br />

(23).<br />

For 135° corners, additional 2 x Positioning<br />

Pins 135° outside (13.1).<br />

(Fig. B3.02)<br />

Stopend formwork with<br />

timber and plywood fillers<br />

For wall thicknesses up to 36.5 cm.<br />

Consisting of:<br />

– 3 x Compensation Waler DAR 80 (24)<br />

– 6 x Stopend Tie DSA (25) with Wingnut<br />

Pivot Plate<br />

– 6 x Top Tie Bracket DAH (55) with<br />

Frame Spanner DW 15<br />

(Fig. B3.03)<br />

32<br />

23<br />

13.1<br />

min. 75°<br />

max.<br />

165°<br />

13.1<br />

55<br />

24<br />

25<br />

Fig. B3.01<br />

Fig. B3.02<br />

Fig. B3.03<br />

Assembly Instructions for Standard Configuration

<strong>DOMINO</strong> <strong>Panel</strong> <strong>Formwork</strong><br />

B4 <strong>DOMINO</strong> 275<br />

Stopend panel reinforcement<br />

with water bar<br />

Consisting of:<br />

– 2 x Outside Pieces AT 3 (56) for approx.<br />

2.5 cm concrete cover or 2 x AT 5 for<br />

approx. 5 cm concrete covering<br />

– 1 x Centre Piece MTF (57)<br />

(Fig. B4.01)<br />

The rubber lip (56.1) allows a continuous<br />

reinforcement thickness of 16 mm.<br />

Assembly without and with water bar<br />

or expandable water bar: see A12.<br />

Installation (Fig. B4.02)<br />

Concrete cover c:<br />

d - b<br />

c = - Ø<br />

2<br />

c<br />

c<br />

b<br />

c<br />

c<br />

b<br />

Reinforcement<br />

d<br />

d<br />

56.1<br />

Fig. B4.01<br />

Assembly Instructions for Standard Configuration<br />

57 MTF<br />

H = 2,75 m<br />

AT 275x3<br />

AT 275x5<br />

56 AT<br />

MT 275x20<br />

MT 275x24/25<br />

MT 275x30<br />

MT 275x35/36<br />

MTF 275x20<br />

MTF 275x24/25<br />

MTF 275x30<br />

MTF 275x35/36<br />

56.1<br />

16 mm<br />

56 57<br />

16 mm<br />

Fig. B4.02<br />

Wall thickness d [cm]<br />

b<br />

Concrete cover approx. 25 mm Concrete cover approx. 50 mm<br />

[mm] 20 24/25 30 35/36 24/25 30 35/36 40<br />

– 2 2 2 2<br />

– 2 2 2 2<br />

without water bar without water bar<br />

118 1 1<br />

158 1 1<br />

218 1 1<br />

268 1 1<br />

with water bar<br />

with water bar<br />

118 1 1<br />

158 1 1<br />

218 1 1<br />

268 1 1<br />

33

<strong>DOMINO</strong> <strong>Panel</strong> <strong>Formwork</strong><br />

B5 <strong>DOMINO</strong> 275<br />

Extension guidelines for<br />

horizontal pre-assembly up<br />

to h = 5.25 m<br />

See also A14 Extensions.<br />

5.25 m<br />

34<br />

2.50 m<br />

2.75 m<br />

25 cm<br />

50 cm<br />

75 cm<br />

5.00 m<br />

25<br />

1.00 m<br />

1.00 m<br />

2.75 m<br />

2.75 m<br />

Assembly Instructions for Standard Configuration

Assembly Instructions for Standard Configuration<br />

35

<strong>DOMINO</strong> <strong>Panel</strong> <strong>Formwork</strong><br />

C1 <strong>DOMINO</strong> 300 <strong>Panel</strong>s<br />

Height [cm]<br />

Key<br />

S) <strong>Panel</strong>s with steel frames<br />

(red powder-coated)<br />

A) <strong>Panel</strong>s with aluminium frames<br />

(yellow powder-coated)<br />

N) Standard elements or multi-purpose panels<br />

H) Timber panels<br />

36<br />

275<br />

125<br />

75<br />

100 75 50<br />

Width [cm]<br />

25 75<br />

S) A)<br />

S) S)<br />

S)<br />

S) A)<br />

S)<br />

S)<br />

S)<br />

S)<br />

Alu panels<br />

When using the Alu panels, the same<br />

formwork guidelines apply as for the<br />

H = 250 connections and extensions.<br />

S)<br />

S)<br />

S)<br />

S) N) A) A) A)<br />

S) A) N)<br />

S) N)<br />

DGE DAW DWD DPA<br />

A)<br />

A)<br />

Assembly Instructions for Standard Configuration<br />

A)<br />

A)<br />

A)<br />

A)<br />

H)<br />

H)

<strong>DOMINO</strong> <strong>Panel</strong> <strong>Formwork</strong><br />

C2 <strong>DOMINO</strong> 300<br />

Standard joint<br />

3 x Alignment Coupler DRS (20).<br />

(Fig. C2.01)<br />

External Corner 90°<br />

3 x Alignment Coupler DRS per side.<br />

(Fig. C2.02)<br />

Internal Corner 90°<br />

3 x Alignment Coupler DRS per side.<br />

(Fig. C2.03)<br />

Fig. C2.02<br />

Assembly Instructions for Standard Configuration<br />

20<br />

Fig. C2.03<br />

Fig. C2.01<br />

37

<strong>DOMINO</strong> <strong>Panel</strong> <strong>Formwork</strong><br />

C3 <strong>DOMINO</strong> 300<br />

Internal articulated corner<br />

4 x Alignment Coupler DRS per side.<br />

For 135° corners, additional 2 x Positioning<br />

Pins 135° inside (13.1).<br />

(Fig. C3.01)<br />

External articulated corner<br />

5 x Alignment Coupler DRS per side<br />

and 2 x Compensation Waler DAR 80<br />

(23).<br />

For 135° corners, additional 2 x Positioning<br />

Pins 135° outside (13.1).<br />

(Fig. C3.02)<br />

38<br />

23<br />

13.1<br />

min. 75°<br />

max. 165°<br />

13.1<br />

Fig. C3.01<br />

Fig. C3.02<br />

Assembly Instructions for Standard Configuration

<strong>DOMINO</strong> <strong>Panel</strong> <strong>Formwork</strong><br />

C4 <strong>DOMINO</strong> 300<br />

Stopend formwork with<br />

timber and plywood fillers<br />

For wall thicknesses up to 36.5 cm.<br />

Consisting of:<br />

– 3 x Compensation Waler DAR 80 (24)<br />

– 6 x Stopend Tie DSA (25) with Wingnut<br />

Pivot Plate<br />

– 6 x Top Tie Bracket DAH (55) with<br />

Frame Spanner DW 15<br />

(Fig. C4.01)<br />

Extension guidelines for<br />

horizontal pre-assembly up<br />

to h = 5.0 m<br />

See also A14 Extensions.<br />

cm<br />

3.0 m<br />

1.25 m<br />

75<br />

Fig. C4.01<br />

25 cm 50 cm<br />

75 cm<br />

1.0 m<br />

3.0 m<br />

Assembly Instructions for Standard Configuration<br />

m<br />

5.0<br />

m<br />

1.0<br />

m<br />

3.0 m<br />

1.0<br />

55<br />

24<br />

25<br />

39

<strong>DOMINO</strong> <strong>Panel</strong> <strong>Formwork</strong><br />

Item no. Weight kg<br />

066020 87,700 <strong>Panel</strong> D 250 x 100<br />

<strong>Panel</strong> with steel frame and formlining 15 mm.<br />

40<br />

066022 71,600 <strong>Panel</strong> D 250 x 75<br />

<strong>Panel</strong> with steel frame and formlining 15 mm.<br />

066025 54,500 <strong>Panel</strong> D 250 x 50<br />

<strong>Panel</strong> with steel frame and formlining 15 mm.<br />

530 1440 530<br />

2500<br />

1000 117<br />

530 1440 530<br />

2500<br />

750 117<br />

530 1440 530<br />

2500<br />

500 117

<strong>DOMINO</strong> <strong>Panel</strong> <strong>Formwork</strong><br />

Item no. Weight kg<br />

066026 37,700 <strong>Panel</strong> D 250 x 25<br />

<strong>Panel</strong> with steel frame and formlining 15 mm.<br />

066021 59,500 <strong>Panel</strong> DA 250 x 100<br />

<strong>Panel</strong> with aluminium frame and formlining 15<br />

mm.<br />

066023 47,500 <strong>Panel</strong> DA 250 x 75<br />

<strong>Panel</strong> with aluminium frame and formlining 15<br />

mm.<br />

530 1440 530<br />

2500<br />

250 117<br />

530 1440 530<br />

2500<br />

1000 117<br />

530 1440 530<br />

2500<br />

750 117<br />

41

<strong>DOMINO</strong> <strong>Panel</strong> <strong>Formwork</strong><br />

Item no. Weight kg<br />

066024<br />

066032<br />

42<br />

76,500<br />

50,200<br />

Multi <strong>Panel</strong>s DM/DMA 250<br />

Multi <strong>Panel</strong> DM 250 x 75<br />

Multi <strong>Panel</strong> DMA 250 x 75<br />

<strong>Panel</strong> Steel/Alu with formlining 15 mm. For oblique<br />

angles, wall connections etc..<br />

066029 39,000 Articulated Corner DGE 250<br />

Made of aluminium. For oblique angles from 75°<br />

for the outside and inside.<br />

066030<br />

101986<br />

7,820<br />

11,600<br />

Wall Thickness Compensations DWD 250<br />

Wall Thickness Compensation DWD 250 x 5<br />

Wall Thickness Compensation DWD 250 x 10<br />

For infills using 21 mm and 27 mm plywood.<br />

Complete with<br />

46 x 030290 Plug Ø 20 mm<br />

530 1440 530<br />

2500<br />

750<br />

45 22 x 30 = 660 45<br />

Complete with<br />

2 x 066100 Corner Locking DEA 90°<br />

530 1440 530<br />

2500<br />

530 1440 530<br />

2500<br />

27 50 27<br />

100<br />

117<br />

250 250 250<br />

117<br />

117<br />

117

<strong>DOMINO</strong> <strong>Panel</strong> <strong>Formwork</strong><br />

Item no. Weight kg<br />

066028 10,500 Outside Corner Angle DAW 250<br />

For panel connections at 90 ° external corners.<br />

066033<br />

066034<br />

4,150<br />

3,920<br />

Filler Supports DPA 250<br />

Filler Support DPA 250<br />

Filler Support DPA 250/27<br />

For infills using 21 mm and 27 mm plywood.<br />

111603 148,000 Shaft <strong>Panel</strong> DSE 275<br />

For lifting complete internal formwork in shafts.<br />

2500<br />

2490<br />

45<br />

117<br />

93 / 87<br />

117<br />

Safety information<br />

Load-bearing point: max. capacity 2.0 t.<br />

2750<br />

500<br />

117<br />

43

<strong>DOMINO</strong> <strong>Panel</strong> <strong>Formwork</strong><br />

Item no. Weight kg<br />

111665 4,360 Spindle Shaft <strong>Panel</strong> DSE<br />

For use with Shaft <strong>Panel</strong> DSE. For spindling back<br />

to the starting position. 1 piece per Shaft <strong>Panel</strong><br />

DSE.<br />

101927<br />

108855<br />

101928<br />

101929<br />

101930<br />

101931<br />

44<br />

16,200<br />

17,900<br />

27,100<br />

31,200<br />

36,000<br />

39,700<br />

Stopend <strong>Panel</strong>s <strong>DOMINO</strong> AT 250<br />

Stopend <strong>Panel</strong> <strong>DOMINO</strong> AT 250 x 3<br />

Stopend <strong>Panel</strong> <strong>DOMINO</strong> AT 250 x 5<br />

Outside Piece for stopend formwork.<br />

Stopend <strong>Panel</strong>s <strong>DOMINO</strong> MTF 250<br />

Stopend <strong>Panel</strong> <strong>DOMINO</strong> MTF 250 x 20<br />

Stopend <strong>Panel</strong> <strong>DOMINO</strong> MTF 250 x 24/25<br />

Stopend <strong>Panel</strong> <strong>DOMINO</strong> MTF 250 x 30<br />

Stopend <strong>Panel</strong> <strong>DOMINO</strong> MTF 250 x 35/36<br />

With expansion joint for stopend formwork.<br />

Complete with<br />

2 x 105822 Pin Ø 20 x 102, galv.<br />

2 x 022230 Cotter Pin 5/1, galv.<br />

Note<br />

Spanner size SW 24.<br />

150<br />

230<br />

SW 24<br />

248<br />

Note<br />

Concrete cover approx. 30 or 50 mm.<br />

2500<br />

B<br />

118<br />

158<br />

218<br />

268<br />

2500<br />

210<br />

117<br />

66<br />

AT 250 x 3 AT 250 x 5<br />

B<br />

120<br />

210<br />

117

<strong>DOMINO</strong> <strong>Panel</strong> <strong>Formwork</strong><br />

Item no. Weight kg<br />

066040 47,300 <strong>Panel</strong> D 125 x 100<br />

<strong>Panel</strong> with steel frame and formlining 15 mm.<br />

066041 38,700 <strong>Panel</strong> D 125 x 75<br />

<strong>Panel</strong> with steel frame and formlining 15 mm.<br />

066043 28,600 <strong>Panel</strong> D 125 x50<br />

<strong>Panel</strong> with steel frame and formlining 15 mm.<br />

066044 18,600 <strong>Panel</strong> D 125 x 25<br />

<strong>Panel</strong> with steel frame and formlining 15 mm.<br />

280 930 40<br />

1250<br />

1000 117<br />

40 240 930 40<br />

1250<br />

750 117<br />

280 930 40<br />

1250<br />

500 117<br />

280 930 40<br />

1250<br />

250 117<br />

45

<strong>DOMINO</strong> <strong>Panel</strong> <strong>Formwork</strong><br />

Item no. Weight kg<br />

066050 31,000 <strong>Panel</strong> DA 125 x 100<br />

<strong>Panel</strong> with aluminium frame and formlining 15<br />

mm.<br />

46<br />

066051 24,800 <strong>Panel</strong> DA 125 x 75<br />

<strong>Panel</strong> with aluminium frame and formlining 15<br />

mm.<br />

066042<br />

066052<br />

43,700<br />

27,300<br />

Multi <strong>Panel</strong>s DM/DMA 125<br />

Multi <strong>Panel</strong> DM 125 x 75<br />

Multi <strong>Panel</strong> DMA 125 x 75<br />

<strong>Panel</strong> Steel/Alu with formlining 15 mm. For oblique<br />

angle, wall connections etc..<br />

066047 21,300 Articulated Corner DGE 125<br />

Made of aluminium. For oblique angles from 75°<br />

for the outside and inside.<br />

1000<br />

40 240 930 40<br />

1250<br />

280 930 40<br />

1250<br />

750 117<br />

117<br />

Complete with<br />

46 x 030290 Plug Ø 20 mm<br />

280 932 38<br />

1250<br />

750<br />

45 22 x 30 = 660 45<br />

Complete with<br />

1 x 066100 Corner Locking DEA 90°<br />

280 930 40<br />

1250<br />

250 250<br />

117<br />

250<br />

117

<strong>DOMINO</strong> <strong>Panel</strong> <strong>Formwork</strong><br />

Item no. Weight kg<br />

066048<br />

101964<br />

4,030<br />

5,940<br />

Wall Thickness Compensators DWD 125<br />

Wall Thickness Compensator DWD 125 x 5<br />

Wall Thickness Compensator DWD 125 x 10<br />

For adaptating to different wall thicknesses.<br />

066046 5,490 Outside Corner Angle DAW 125<br />

For panel connections at 90 ° external corners.<br />

066053<br />

066054<br />

2,070<br />

1,950<br />

Filler Supports DPA 125<br />

Filler Support DPA 125<br />

Filler Support DPA 125/27<br />

For infills using 21 mm and 27 mm plywood.<br />

111655 77,100 Shaft <strong>Panel</strong> DSE 125<br />

For lifting complete internal formwork in shafts.<br />

280 930 40<br />

1250<br />

1250<br />

1240<br />

45<br />

27<br />

117<br />

93 / 87<br />

50<br />

117<br />

117<br />

27<br />

100<br />

117<br />

Safety information<br />

Load-bearing point: max. capacity 2.0 t.<br />

1250<br />

500<br />

117<br />

47

<strong>DOMINO</strong> <strong>Panel</strong> <strong>Formwork</strong><br />

Item no. Weight kg<br />

101934<br />

108856<br />

101935<br />

101936<br />

101937<br />

101940<br />

48<br />

8,140<br />

8,980<br />

14,600<br />

15,200<br />

17,500<br />

19,300<br />

Stopend <strong>Panel</strong>s <strong>DOMINO</strong> AT 125<br />

Stopend <strong>Panel</strong> <strong>DOMINO</strong> AT 125 x 3<br />

Stopend <strong>Panel</strong> <strong>DOMINO</strong> AT 125 x 5<br />

Outside Piece for stopend formwork.<br />

Stopend <strong>Panel</strong>s <strong>DOMINO</strong> MTF 125<br />

Stopend <strong>Panel</strong> <strong>DOMINO</strong> MTF 125 x 20<br />

Stopend <strong>Panel</strong> <strong>DOMINO</strong> MTF 125 x 24/25<br />

Stopend <strong>Panel</strong> <strong>DOMINO</strong> MTF 125 x 30<br />

Stopend <strong>Panel</strong> <strong>DOMINO</strong> MTF 125 x 35/36<br />

With expansion joint for stopend formwork.<br />

066064 12,100 <strong>Panel</strong> D 75 x 25<br />

<strong>Panel</strong> with steel frame and formlining 15 mm.<br />

066063 19,300 <strong>Panel</strong> D 75 x 50<br />

<strong>Panel</strong> with steel frame and formlining 15 mm.<br />

066061 26,600 <strong>Panel</strong> D 75 x 75<br />

<strong>Panel</strong> with steel frame and formlining 15 mm.<br />

Note<br />

Concrete cover approx. 30 or 50 mm.<br />

1250<br />

B<br />

118<br />

158<br />

218<br />

268<br />

1250<br />

280 430 40<br />

750<br />

250 117<br />

500<br />

750<br />

280 430 40<br />

750<br />

AT 125x3 AT 125x5<br />

210<br />

B<br />

117<br />

280 430 40<br />

750<br />

120<br />

117<br />

117<br />

210<br />

117

<strong>DOMINO</strong> <strong>Panel</strong> <strong>Formwork</strong><br />

Item no. Weight kg<br />

066060 32,400 <strong>Panel</strong> D 75 x 100<br />

<strong>Panel</strong> with steel frame and formlining 15 mm.<br />

066062 31,600 Multi <strong>Panel</strong> DM 75 x 75<br />

<strong>Panel</strong> with steel frame and formlining 15 mm. For<br />

oblique angles, wall connections, stopend formwork<br />

etc.<br />

066067 12,800 Articulated Corner DGE 75<br />

Made of aluminium. For oblique angles from 75°<br />

for the outside and inside.<br />

066068 2,520 Wall Thickness Compensator DWD 75 x 5<br />

For adaptating to different wall thicknesses.<br />

066066 3,500 Outside Corner Angle DAW 75<br />

For panel connections at 90 ° external corners.<br />

1000<br />

280 430 40<br />

750<br />

117<br />

Complete with<br />

23 x 030290 Plug Ø 20 mm<br />

280 432 38<br />

750<br />

750<br />

45 22 x 30 = 660 45<br />

Complete with<br />

1 x 066100 Corner Locking DEA 90°<br />

280 430 40<br />

750<br />

750<br />

280 430 40<br />

750<br />

27<br />

117<br />

50<br />

117<br />

117<br />

250 250<br />

117<br />

250<br />

117<br />

49

<strong>DOMINO</strong> <strong>Panel</strong> <strong>Formwork</strong><br />

Item no. Weight kg<br />

066035<br />

066036<br />

066037<br />

066038<br />

066055<br />

066056<br />

066057<br />

066058<br />

066070<br />

066071<br />

066072<br />

066073<br />

50<br />

47,100<br />

44,200<br />

41,000<br />

32,800<br />

24,400<br />

22,600<br />

21,200<br />

16,000<br />

16,100<br />

15,100<br />

14,000<br />

9,900<br />

Column <strong>Panel</strong>s DS 250<br />

Column <strong>Panel</strong> DS 250 x 40<br />

Column <strong>Panel</strong> DS 250 x 35<br />

Column <strong>Panel</strong> DS 250 x 30<br />

Column <strong>Panel</strong> DS 250 x 20<br />

<strong>DOMINO</strong> Column <strong>Panel</strong> without anchor holes.<br />

Column <strong>Panel</strong>s DS 125<br />

Column <strong>Panel</strong> DS 125 x 40<br />

Column <strong>Panel</strong> DS 125 x 35<br />

Column <strong>Panel</strong> DS 125 x 30<br />

Column <strong>Panel</strong> DS 125 x 20<br />

<strong>DOMINO</strong> Column <strong>Panel</strong> without anchor holes.<br />

Column <strong>Panel</strong>s DS 75<br />

Column <strong>Panel</strong> DS 75 x 40<br />

Column <strong>Panel</strong> DS 75 x 35<br />

Column <strong>Panel</strong> DS 75 x 30<br />

Column <strong>Panel</strong> DS 75 x 20<br />

<strong>DOMINO</strong> Column <strong>Panel</strong> without anchor holes.<br />

B<br />

400<br />

350<br />

300<br />

200<br />

2500<br />

B 117<br />

B<br />

400<br />

350<br />

300<br />

200<br />

1250<br />

B 117<br />

B<br />

400<br />

350<br />

300<br />

200<br />

750<br />

B 117

<strong>DOMINO</strong> <strong>Panel</strong> <strong>Formwork</strong><br />

Item no. Weight kg<br />

066088 2,030 Chamfer Strip DSD 250<br />

For <strong>DOMINO</strong> Column <strong>Formwork</strong> and external corners.<br />

066100 1,470 Corner Locking DEA 90°<br />

For 90° inside corners.<br />

066095 1,060 Positioning Pin DGE 135° internal<br />

For 135° internal corners<br />

066097 1,560 Positioning Pin DGE 135° external<br />

For 135° external corners.<br />

2500<br />

141<br />

60<br />

165<br />

141<br />

Complete with<br />

2 x 710224 Hex. Bolt ISO 4017 M12 x 40-8.8, galv.<br />

M 12x40<br />

308<br />

40<br />

Complete with<br />

2 x 710224 Hex. Bolt ISO 4017 M12 x 40-8.8, galv.<br />

M 12x40<br />

470<br />

120<br />

40<br />

120<br />

51

<strong>DOMINO</strong> <strong>Panel</strong> <strong>Formwork</strong><br />

Item no. Weight kg<br />

066080 3,630 Alignment Coupler DRS<br />

For all <strong>DOMINO</strong> panel connections.<br />

Compensations up to 12 cm possible.<br />

52<br />

066081 1,160 Wedge Clamp DKS<br />

For standard <strong>DOMINO</strong> panel connections not<br />

under high load.<br />

066084 8,510 Compensation Waler DAR 80<br />

For length compensations, height extensions,<br />

stopend formwork and special applications for<br />

<strong>DOMINO</strong>. With captive connection components.<br />

066085 6,570 Scaffold Bracket DG 85<br />

For assembly of working and concreting scaffolds<br />

for <strong>DOMINO</strong>.<br />

034580 3,520<br />

Accessories<br />

Handrail Post HSGP<br />

max 173<br />

288<br />

151<br />

790<br />

127<br />

109<br />

40<br />

40<br />

Technical Data<br />

Permissible load 150 kg/m 2 with maximum width<br />

of influence 2.00 m.<br />

1044<br />

25<br />

112<br />

653<br />

133<br />

60<br />

61<br />

259<br />

165<br />

45

<strong>DOMINO</strong> <strong>Panel</strong> <strong>Formwork</strong><br />

Item no. Weight kg<br />

106877 2,730 Handrail Post Holder <strong>DOMINO</strong><br />

For assembly of guardrails on <strong>DOMINO</strong> panels.<br />

034580 3,520<br />

Accessories<br />

Handrail Post HSGP<br />

034580 3,520 Handrail Post HSGP<br />

As guardrail for different systems.<br />

066082 1,040 Push-Pull Prop Connector DRA<br />

For connecting push-pull props and kickers to<br />

<strong>DOMINO</strong> panels.<br />

Complete with<br />

1 x 018060 Cotter Pin 4/1, galv.<br />

Technical Data<br />

Maximum width of influence 2.00 m.<br />

142<br />

65 35<br />

120<br />

440<br />

1050<br />

146<br />

1300<br />

349<br />

Complete with<br />

1 x 027170 Pin Ø 16 x 42, galv.<br />

1 x 018060 Cotter Pin 4/1, galv.<br />

117<br />

Ø16x42<br />

120 98<br />

68<br />

28<br />

213<br />

53

<strong>DOMINO</strong> <strong>Panel</strong> <strong>Formwork</strong><br />