Modern Plastics Worldwide - July/August 2009 - dae uptlax

Modern Plastics Worldwide - July/August 2009 - dae uptlax

Modern Plastics Worldwide - July/August 2009 - dae uptlax

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

PROCESSING TECHNOLOGY<br />

MATERIAL THOUGHTS<br />

Technology drives new<br />

class of elastomers<br />

Eliminating the oils and plasticizers typically used to soften the<br />

materials, a new class of elastomers claims to offer higher performance<br />

for longer durations at more temperature extremes.<br />

Wayne Rodrigue, CEO Exousia Advanced Materials, told<br />

MPW his company’s RPA thermoplastic olefin (TPO) also<br />

eliminates exposure to hydrogen peroxide as a manufacturing<br />

step with a proprietary process that results in covalent bonding<br />

between the crosslinked rubber and its olefin matrix.<br />

Coming to market with 14 formulations, Exousia has<br />

spent the last two years developing commercial applications<br />

for the technology and proving its viability. This work<br />

included testing with General Motors to the have the resin<br />

validated for use in automotive components. Exousia says<br />

theses tests proved the material dimensionally stable from<br />

-40°F to 140°F. While oils and plasticizers can bleach out<br />

New HDPE, PP grades<br />

boost fi lm properties<br />

The latest additions to the Alathon<br />

family of film resins include two new<br />

medium-molecular-weight (MMW), highdensity<br />

polyethylene (HDPE) materials,<br />

which promise moisture barrier, low<br />

gels, and excellent organoleptic properties.<br />

Alathon M6010 and Alathon M5010<br />

have improved moisture barrier for dryfood<br />

packaging applications like cereal,<br />

snack crackers, and cake-mix box liners.<br />

An MI homopolymer, LyondellBasell says<br />

lab tests have shown that Alathon M6010<br />

increased moisture barrier vs. benchmark<br />

grades by approximately 30% without<br />

affecting processability, tear, and impact.<br />

The material also offers oxygen barrier.<br />

Alathon M5010 is a 1 MI copolymer<br />

resin designed to improve toughness for a<br />

variety of films, including mono- and multilayer<br />

structures. LyondellBasell says the tear<br />

performance of film made from the material<br />

has been increased 20%, while high-speed<br />

puncture resistance was boosted by 40%.<br />

Alathon M6010 and Alathon M5010 are<br />

currently manufactured in the U.S. and<br />

available for export.<br />

In blown polypropylene (PP) films,<br />

LyondellBasell has launched a grade based<br />

on its proprietary Catalloy technology<br />

that offers a combination of transparency<br />

and impact, puncture, and tear resistance.<br />

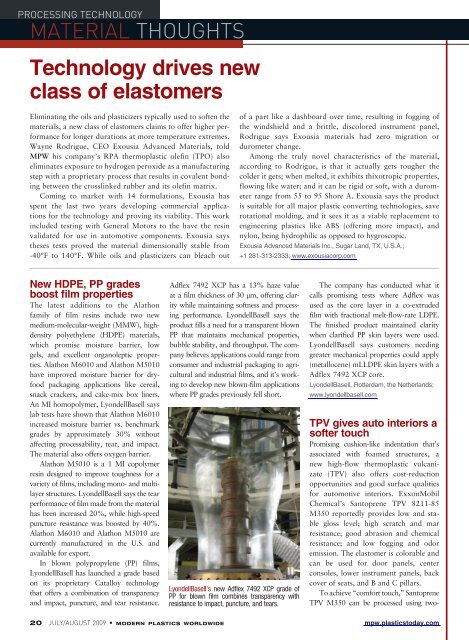

Adflex 7492 XCP has a 13% haze value<br />

at a film thickness of 30 μm, offering clarity<br />

while maintaining softness and processing<br />

performance. LyondellBasell says the<br />

product fills a need for a transparent blown<br />

PP that maintains mechanical properties,<br />

bubble stability, and throughput. The company<br />

believes applications could range from<br />

consumer and industrial packaging to agricultural<br />

and industrial films, and it’s working<br />

to develop new blown-film applications<br />

where PP grades previously fell short.<br />

LyondellBasell’s new Adflex 7492 XCP grade of<br />

PP for blown film combines transparency with<br />

resistance to impact, puncture, and tears.<br />

of a part like a dashboard over time, resulting in fogging of<br />

the windshield and a brittle, discolored instrument panel,<br />

Rodrigue says Exousia materials had zero migration or<br />

durometer change.<br />

Among the truly novel characteristics of the material,<br />

according to Rodrigue, is that it actually gets tougher the<br />

colder it gets; when melted, it exhibits thixotropic properties,<br />

flowing like water; and it can be rigid or soft, with a durometer<br />

range from 55 to 95 Shore A. Exousia says the product<br />

is suitable for all major plastic converting technologies, save<br />

rotational molding, and it sees it as a viable replacement to<br />

engineering plastics like ABS (offering more impact), and<br />

nylon, being hydrophilic as opposed to hygroscopic.<br />

Exousia Advanced Materials Inc., Sugar Land, TX, U.S.A.;<br />

+1 281-313-2333; www.exousiacorp.com<br />

The company has conducted what it<br />

calls promising tests where Adflex was<br />

used as the core layer in a co-extruded<br />

film with fractional melt-flow-rate LDPE.<br />

The finished product maintained clarity<br />

when clarified PP skin layers were used.<br />

LyondellBasell says customers needing<br />

greater mechanical properties could apply<br />

(metallocene) mLLDPE skin layers with a<br />

Adflex 7492 XCP core.<br />

LyondellBasell, Rotterdam, the Netherlands;<br />

www.lyondellbasell.com<br />

TPV gives auto interiors a<br />

softer touch<br />

Promising cushion-like indentation that’s<br />

associated with foamed structures, a<br />

new high-flow thermoplastic vulcanizate<br />

(TPV) also offers cost-reduction<br />

opportunities and good surface qualities<br />

for automotive interiors. ExxonMobil<br />

Chemical’s Santoprene TPV 8211-85<br />

M350 reportedly provides low and stable<br />

gloss level; high scratch and mar<br />

resistance; good abrasion and chemical<br />

resistance; and low fogging and odor<br />

emission. The elastomer is colorable and<br />

can be used for door panels, center<br />

consoles, lower instrument panels, back<br />

cover of seats, and B and C pillars.<br />

To achieve “comfort touch,” Santoprene<br />

TPV M350 can be processed using two-<br />

20 JULY/AUGUST <strong>2009</strong> • MODERN PLASTICS WORLDWIDE mpw.plasticstoday.com