Modern Plastics Worldwide - July/August 2009 - dae uptlax

Modern Plastics Worldwide - July/August 2009 - dae uptlax

Modern Plastics Worldwide - July/August 2009 - dae uptlax

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

WORLD TOUR<br />

EUROPE<br />

Business, Strategies & Markets<br />

Innovation key to future for Serbian<br />

processors<br />

By Robert Colvin<br />

Barrier-film processor Spektar (Gornji<br />

Milanovac), after installing a 7-layer,<br />

biaxially oriented, blown shrink-wrap line<br />

from Kuhne Anlagebau (Sankt <strong>August</strong>in,<br />

Germany) five years ago (April 2004<br />

MPW, p. 45), has embarked on a project<br />

offering even higher barrier. The<br />

processor was named 2007 Exporter of<br />

the Year by the government for its innovative<br />

packaging products, which are<br />

sent to markets throughout Europe, the<br />

surrounding Balkan states of the former<br />

Yugoslavia, Russia/CIS countries, and<br />

even North America, where the processor<br />

is eager to find a distributor.<br />

Spektar owner Zoran Dordevic,<br />

together with his two sons, has opted<br />

for a 9-layer, triple bubble system, producing<br />

web in 25-100-μm tolerances, on<br />

a line delivered from Kuhne but with its<br />

design based on Spektar’s 5- and 7-layer<br />

production experience, he says. The new<br />

unit allows up to 50%<br />

better shrink properties<br />

for packaging of meats<br />

and cheese.<br />

Son Petar Dordevic<br />

says the unit will complement<br />

the company’s<br />

offering since 7-layer<br />

film (40-100 μm) produced<br />

there provides<br />

better puncture resistance<br />

for packaging<br />

such things as fresh<br />

meat with sharp bones.<br />

“We want to be able<br />

to offer customers the<br />

optimum choice of film<br />

structures to match<br />

their products,” he<br />

says.<br />

Petar Dordevic adds<br />

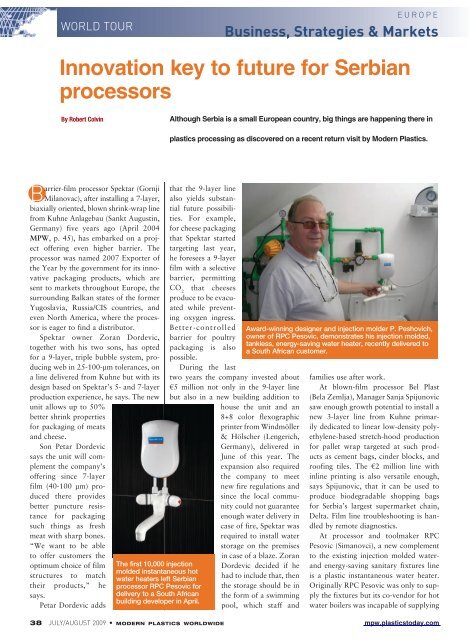

The first 10,000 injection<br />

molded instantaneous hot<br />

water heaters left Serbian<br />

processor RPC Pesovic for<br />

delivery to a South African<br />

building developer in April.<br />

Although Serbia is a small European country, big things are happening there in<br />

plastics processing as discovered on a recent return visit by <strong>Modern</strong> <strong>Plastics</strong>.<br />

that the 9-layer line<br />

also yields substantial<br />

future possibilities.<br />

For example,<br />

for cheese packaging<br />

that Spektar started<br />

targeting last year,<br />

he foresees a 9-layer<br />

film with a selective<br />

barrier, permitting<br />

CO 2 that cheeses<br />

produce to be evacuated<br />

while preventing<br />

oxygen ingress.<br />

Better-controlled<br />

barrier for poultry<br />

packaging is also<br />

possible.<br />

During the last<br />

two years the company invested about<br />

€5 million not only in the 9-layer line<br />

but also in a new building addition to<br />

house the unit and an<br />

8+8 color flexographic<br />

printer from Windmöller<br />

& Hölscher (Lengerich,<br />

Germany), delivered in<br />

June of this year. The<br />

expansion also required<br />

the company to meet<br />

new fire regulations and<br />

since the local community<br />

could not guarantee<br />

enough water delivery in<br />

case of fire, Spektar was<br />

required to install water<br />

storage on the premises<br />

Award-winning designer and injection molder P. Peshovich,<br />

owner of RPC Pesovic, demonstrates his injection molded,<br />

tankless, energy-saving water heater, recently delivered to<br />

a South African customer.<br />

in case of a blaze. Zoran<br />

Dordevic decided if he<br />

had to include that, then<br />

the storage should be in<br />

the form of a swimming<br />

pool, which staff and<br />

families use after work.<br />

At blown-film processor Bel Plast<br />

(Bela Zemlja), Manager Sanja Spijunovic<br />

saw enough growth potential to install a<br />

new 3-layer line from Kuhne primarily<br />

dedicated to linear low-density polyethylene-based<br />

stretch-hood production<br />

for pallet wrap targeted at such products<br />

as cement bags, cinder blocks, and<br />

roofing tiles. The €2 million line with<br />

inline printing is also versatile enough,<br />

says Spijunovic, that it can be used to<br />

produce biodegradable shopping bags<br />

for Serbia’s largest supermarket chain,<br />

Delta. Film line troubleshooting is handled<br />

by remote diagnostics.<br />

At processor and toolmaker RPC<br />

Pesovic (Simanovci), a new complement<br />

to the existing injection molded water-<br />

and energy-saving sanitary fixtures line<br />

is a plastic instantaneous water heater.<br />

Originally RPC Pesovic was only to supply<br />

the fixtures but its co-vendor for hot<br />

water boilers was incapable of supplying<br />

38 JULY/AUGUST <strong>2009</strong> • MODERN PLASTICS WORLDWIDE mpw.plasticstoday.com