Controls Start-Up, Operation, Service, and ... - Climayoreo

Controls Start-Up, Operation, Service, and ... - Climayoreo

Controls Start-Up, Operation, Service, and ... - Climayoreo

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

RETURN<br />

FLUID<br />

RETURN<br />

FLUID<br />

To configure the two chillers for operation, follow the<br />

example shown in Tables 24A <strong>and</strong> 24B. The master chiller will<br />

be configured with a slave chiller at address 2. Also in this example,<br />

the master chiller will be configured to use Lead/Lag<br />

Balance to even out the chiller runtimes weekly. The Lag <strong>Start</strong><br />

Delay feature will be set to 10 minutes. The chillers will be<br />

configured for parallel fluid flow. The master <strong>and</strong> slave chillers<br />

cannot have the same CCN address (CCNA, Configuration<br />

mode under OPT2). In addition, the chillers must be connected<br />

together on the same CCN bus. Connections can be made to<br />

the CCN screw terminals on TB3 in both chillers. The master<br />

chiller will determine which chiller will be Lead <strong>and</strong> which<br />

will be Lag. The master chiller controls the slave chiller by<br />

forcing the slave chiller ON <strong>and</strong> OFF, <strong>and</strong> forcing the control<br />

RUN<br />

STATUS<br />

SERVICE<br />

TEST<br />

TEMPERATURES PRESSURES<br />

Auto Manual<br />

Unit<br />

Ckt A<br />

Display Mode Temperatures Pressures<br />

(VIEW) On/Off<br />

(TEST)<br />

(UNIT) (PRC.A)<br />

Machine Ckt A/B Ckt A<br />

Ckt B<br />

Hours/<strong>Start</strong>s Outputs Temperatures Pressures<br />

(RUN) (OUTS) (CIR.A) (PRC.B)<br />

Compressor Compressor Ckt B<br />

Run Hours Tests Temperatures<br />

(HOUR) (COMP) (CIR.B)<br />

Compressor<br />

<strong>Start</strong>s<br />

(STRT)<br />

Software<br />

Version<br />

(VERS)<br />

LEGEND<br />

Ckt — Circuit<br />

SLAVE<br />

CHILLER<br />

MASTER<br />

CHILLER<br />

SLAVE<br />

CHILLER<br />

MASTER<br />

CHILLER<br />

LEAVING<br />

FLUID<br />

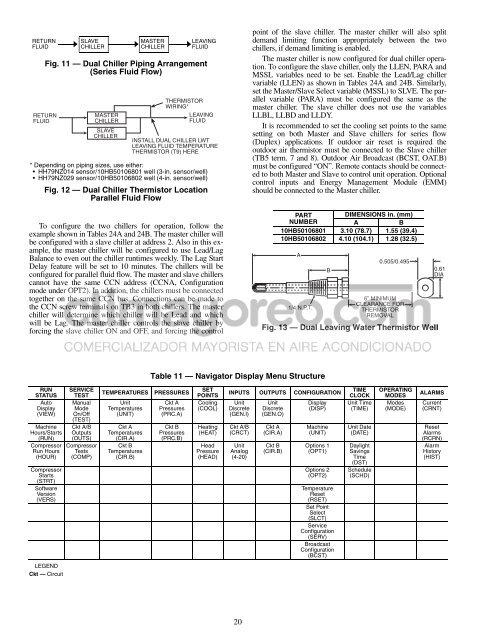

Fig. 11 — Dual Chiller Piping Arrangement<br />

(Series Fluid Flow)<br />

THERMISTOR<br />

WIRING*<br />

LEAVING<br />

FLUID<br />

INSTALL DUAL CHILLER LWT<br />

LEAVING FLUID TEMPERATURE<br />

THERMISTOR (T9) HERE<br />

* Depending on piping sizes, use either:<br />

HH79NZ014 sensor/10HB50106801 well (3-in. sensor/well)<br />

HH79NZ029 sensor/10HB50106802 well (4-in. sensor/well)<br />

Fig. 12 — Dual Chiller Thermistor Location<br />

Parallel Fluid Flow<br />

Table 11 — Navigator Display Menu Structure<br />

SET<br />

POINTS<br />

Cooling<br />

(COOL)<br />

Heating<br />

(HEAT)<br />

Head<br />

Pressure<br />

(HEAD)<br />

20<br />

point of the slave chiller. The master chiller will also split<br />

dem<strong>and</strong> limiting function appropriately between the two<br />

chillers, if dem<strong>and</strong> limiting is enabled.<br />

The master chiller is now configured for dual chiller operation.<br />

To configure the slave chiller, only the LLEN, PARA <strong>and</strong><br />

MSSL variables need to be set. Enable the Lead/Lag chiller<br />

variable (LLEN) as shown in Tables 24A <strong>and</strong> 24B. Similarly,<br />

set the Master/Slave Select variable (MSSL) to SLVE. The parallel<br />

variable (PARA) must be configured the same as the<br />

master chiller. The slave chiller does not use the variables<br />

LLBL, LLBD <strong>and</strong> LLDY.<br />

It is recommended to set the cooling set points to the same<br />

setting on both Master <strong>and</strong> Slave chillers for series flow<br />

(Duplex) applications. If outdoor air reset is required the<br />

outdoor air thermistor must be connected to the Slave chiller<br />

(TB5 term. 7 <strong>and</strong> 8). Outdoor Air Broadcast (BCST, OAT.B)<br />

must be configured “ON”. Remote contacts should be connected<br />

to both Master <strong>and</strong> Slave to control unit operation. Optional<br />

control inputs <strong>and</strong> Energy Management Module (EMM)<br />

should be connected to the Master chiller.<br />

INPUTS OUTPUTS CONFIGURATION<br />

Unit<br />

Discrete<br />

(GEN.I)<br />

Ckt A/B<br />

(CRCT)<br />

Unit<br />

Analog<br />

(4-20)<br />

Unit<br />

Discrete<br />

(GEN.O)<br />

Ckt A<br />

(CIR.A)<br />

Ckt B<br />

(CIR.B)<br />

PART<br />

DIMENSIONS in. (mm)<br />

NUMBER<br />

A B<br />

10HB50106801 3.10 (78.7) 1.55 (39.4)<br />

10HB50106802 4.10 (104.1) 1.28 (32.5)<br />

A<br />

1/4 N.P.T.<br />

Display<br />

(DISP)<br />

Machine<br />

(UNIT)<br />

B<br />

Options 1<br />

(OPT1)<br />

Options 2<br />

(OPT2)<br />

Temperature<br />

Reset<br />

(RSET)<br />

Set Point<br />

Select<br />

(SLCT)<br />

<strong>Service</strong><br />

Configuration<br />

(SERV)<br />

Broadcast<br />

Configuration<br />

(BCST)<br />

TIME<br />

CLOCK<br />

Unit Time<br />

(TIME)<br />

Unit Date<br />

(DATE)<br />

Daylight<br />

Savings<br />

Time<br />

(DST)<br />

Schedule<br />

(SCHD)<br />

0.505/0.495<br />

6” MINIMUM<br />

CLEARANCE FOR<br />

THERMISTOR<br />

REMOVAL<br />

Fig. 13 — Dual Leaving Water Thermistor Well<br />

OPERATING<br />

MODES<br />

Modes<br />

(MODE)<br />

0.61<br />

DIA<br />

ALARMS<br />

Current<br />

(CRNT)<br />

Reset<br />

Alarms<br />

(RCRN)<br />

Alarm<br />

History<br />

(HIST)