Controls Start-Up, Operation, Service, and ... - Climayoreo

Controls Start-Up, Operation, Service, and ... - Climayoreo

Controls Start-Up, Operation, Service, and ... - Climayoreo

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

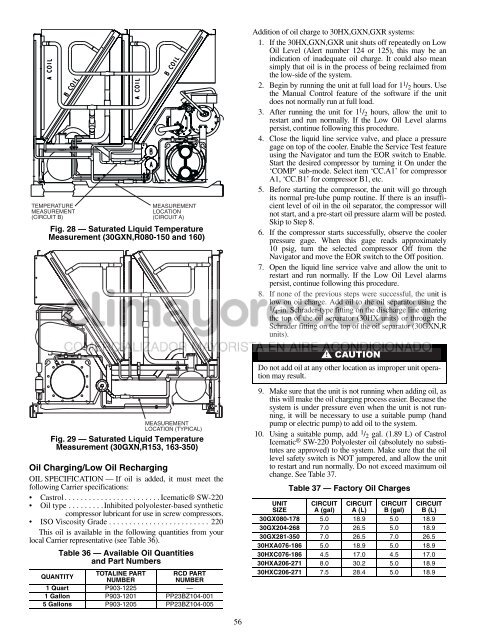

TEMPERATURE<br />

MEASUREMENT<br />

(CIRCUIT B)<br />

MEASUREMENT<br />

LOCATION<br />

(CIRCUIT A)<br />

Fig. 28 — Saturated Liquid Temperature<br />

Measurement (30GXN,R080-150 <strong>and</strong> 160)<br />

MEASUREMENT<br />

LOCATION (TYPICAL)<br />

Fig. 29 — Saturated Liquid Temperature<br />

Measurement (30GXN,R153, 163-350)<br />

Oil Charging/Low Oil Recharging<br />

OIL SPECIFICATION — If oil is added, it must meet the<br />

following Carrier specifications:<br />

Castrol........................Icematic®SW-220<br />

Oil type . . . . . . . . .Inhibited polyolester-based synthetic<br />

compressor lubricant for use in screw compressors.<br />

ISOViscosityGrade.........................220<br />

This oil is available in the following quantities from your<br />

local Carrier representative (see Table 36).<br />

Table 36 — Available Oil Quantities<br />

<strong>and</strong> Part Numbers<br />

QUANTITY<br />

TOTALINE PART<br />

NUMBER<br />

RCD PART<br />

NUMBER<br />

1 Quart P903-1225 —<br />

1Gallon P903-1201 PP23BZ104-001<br />

5Gallons P903-1205 PP23BZ104-005<br />

56<br />

Addition of oil charge to 30HX,GXN,GXR systems:<br />

1. If the 30HX,GXN,GXR unit shuts off repeatedly on Low<br />

Oil Level (Alert number 124 or 125), this may be an<br />

indication of inadequate oil charge. It could also mean<br />

simply that oil is in the process of being reclaimed from<br />

the low-side of the system.<br />

2. Begin by running the unit at full load for 1 1/ 2 hours. Use<br />

the Manual Control feature of the software if the unit<br />

does not normally run at full load.<br />

3. After running the unit for 1 1/ 2 hours, allow the unit to<br />

restart <strong>and</strong> run normally. If the Low Oil Level alarms<br />

persist, continue following this procedure.<br />

4. Close the liquid line service valve, <strong>and</strong> place a pressure<br />

gage on top of the cooler. Enable the <strong>Service</strong> Test feature<br />

using the Navigator <strong>and</strong> turn the EOR switch to Enable.<br />

<strong>Start</strong> the desired compressor by turning it On under the<br />

‘COMP’ sub-mode. Select item ‘CC.A1’ for compressor<br />

A1, ‘CC.B1’ for compressor B1, etc.<br />

5. Before starting the compressor, the unit will go through<br />

its normal pre-lube pump routine. If there is an insufficient<br />

level of oil in the oil separator, the compressor will<br />

not start, <strong>and</strong> a pre-start oil pressure alarm will be posted.<br />

Skip to Step 8.<br />

6. If the compressor starts successfully, observe the cooler<br />

pressure gage. When this gage reads approximately<br />

10 psig, turn the selected compressor Off from the<br />

Navigator <strong>and</strong> move the EOR switch to the Off position.<br />

7. Open the liquid line service valve <strong>and</strong> allow the unit to<br />

restart <strong>and</strong> run normally. If the Low Oil Level alarms<br />

persist, continue following this procedure.<br />

8. If none of the previous steps were successful, the unit is<br />

low on oil charge. Add oil to the oil separator using the<br />

1 /4-in. Schrader-type fitting on the discharge line entering<br />

the top of the oil separator (30HX units) or through the<br />

Schrader fitting on the top of the oil separator (30GXN,R<br />

units).<br />

Do not add oil at any other location as improper unit operation<br />

may result.<br />

9. Make sure that the unit is not running when adding oil, as<br />

this will make the oil charging process easier. Because the<br />

system is under pressure even when the unit is not running,<br />

it will be necessary to use a suitable pump (h<strong>and</strong><br />

pump or electric pump) to add oil to the system.<br />

10. Using a suitable pump, add 1 /2 gal.(1.89L)ofCastrol<br />

Icematic ® SW-220 Polyolester oil (absolutely no substitutes<br />

are approved) to the system. Make sure that the oil<br />

level safety switch is NOT jumpered, <strong>and</strong> allow the unit<br />

to restart <strong>and</strong> run normally. Do not exceed maximum oil<br />

change. See Table 37.<br />

Table 37 — Factory Oil Charges<br />

UNIT CIRCUIT CIRCUIT CIRCUIT CIRCUIT<br />

SIZE A(gal) A(L) B(gal) B(L)<br />

30GX080-178 5.0 18.9 5.0 18.9<br />

30GX204-268 7.0 26.5 5.0 18.9<br />

30GX281-350 7.0 26.5 7.0 26.5<br />

30HXA076-186 5.0 18.9 5.0 18.9<br />

30HXC076-186 4.5 17.0 4.5 17.0<br />

30HXA206-271 8.0 30.2 5.0 18.9<br />

30HXC206-271 7.5 28.4 5.0 18.9