Controls Start-Up, Operation, Service, and ... - Climayoreo

Controls Start-Up, Operation, Service, and ... - Climayoreo

Controls Start-Up, Operation, Service, and ... - Climayoreo

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

different colored wires. At each system element, the shields of<br />

its communication bus cables must be tied together. If the communication<br />

bus is entirely within one building, the resulting<br />

continuous shield must be connected to a ground at one point<br />

only. If the communication bus cable exits from one building<br />

<strong>and</strong> enters another, the shields must be connected to grounds at<br />

the lightning suppressor in each building where the cable<br />

enters or exits the building (one point per building only).<br />

To connect the unit to the network:<br />

1. Turn off power to the control box.<br />

2. Cut the CCN wire <strong>and</strong> strip the ends of the red (+), white<br />

(ground), <strong>and</strong> black (–) conductors. (Substitute appropriate<br />

colors for different colored cables.)<br />

3. Connect the red wire to (+) terminal on TB3, the white<br />

wire to COM terminal, <strong>and</strong> the black wire to the<br />

(–) terminal.<br />

4. The RJ-14 CCN connector on TB3 can also be used, but<br />

is only intended for temporary connection (for example: a<br />

laptop computer running <strong>Service</strong> Tool).<br />

Table 1 — Unit Mode from Control/Enable/Off/<br />

Remote Contact <strong>and</strong> CCN State<br />

SWITCH REMOTE<br />

CCN<br />

CCN UNIT<br />

POSITION CONTACTS CONFIGURATION STATE MODE<br />

DISABLE NR LOCAL ON<br />

ENABLE NR<br />

ENABLE<br />

RUN<br />

STOP<br />

CCN ON<br />

CCN OFF<br />

OFF NR NR NR LOCAL OFF<br />

OPEN NR NR LOCAL OFF<br />

REMOTE<br />

DISABLE NR LOCAL ON<br />

CONTACT CLOSED<br />

LEGEND<br />

ENABLE<br />

RUN<br />

STOP<br />

CCN ON<br />

CCN OFF<br />

CCN — Carrier Comfort Network<br />

NR — Input Not Read by Processor<br />

NOTE: If the unit is configured for a clock, then the unit is under clock control if<br />

it is in an ON mode.<br />

OPERATION DATA<br />

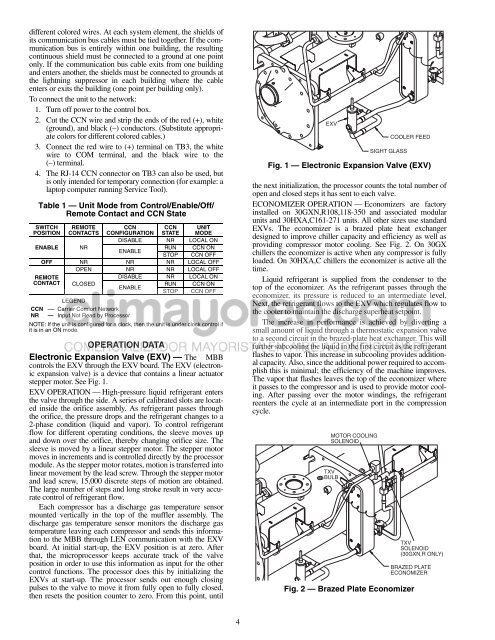

Electronic Expansion Valve (EXV) — The MBB<br />

controls the EXV through the EXV board. The EXV (electronic<br />

expansion valve) is a device that contains a linear actuator<br />

stepper motor. See Fig. 1.<br />

EXV OPERATION — High-pressure liquid refrigerant enters<br />

the valve through the side. A series of calibrated slots are located<br />

inside the orifice assembly. As refrigerant passes through<br />

the orifice, the pressure drops <strong>and</strong> the refrigerant changes to a<br />

2-phase condition (liquid <strong>and</strong> vapor). To control refrigerant<br />

flow for different operating conditions, the sleeve moves up<br />

<strong>and</strong> down over the orifice, thereby changing orifice size. The<br />

sleeve is moved by a linear stepper motor. The stepper motor<br />

moves in increments <strong>and</strong> is controlled directly by the processor<br />

module. As the stepper motor rotates, motion is transferred into<br />

linear movement by the lead screw. Through the stepper motor<br />

<strong>and</strong> lead screw, 15,000 discrete steps of motion are obtained.<br />

The large number of steps <strong>and</strong> long stroke result in very accurate<br />

control of refrigerant flow.<br />

Each compressor has a discharge gas temperature sensor<br />

mounted vertically in the top of the muffler assembly. The<br />

discharge gas temperature sensor monitors the discharge gas<br />

temperature leaving each compressor <strong>and</strong> sends this information<br />

to the MBB through LEN communication with the EXV<br />

board. At initial start-up, the EXV position is at zero. After<br />

that, the microprocessor keeps accurate track of the valve<br />

position in order to use this information as input for the other<br />

control functions. The processor does this by initializing the<br />

EXVs at start-up. The processor sends out enough closing<br />

pulses to the valve to move it from fully open to fully closed,<br />

then resets the position counter to zero. From this point, until<br />

4<br />

EXV<br />

SIGHT GLASS<br />

COOLER FEED<br />

Fig. 1 — Electronic Expansion Valve (EXV)<br />

the next initialization, the processor counts the total number of<br />

open <strong>and</strong> closed steps it has sent to each valve.<br />

ECONOMIZER OPERATION — Economizers are factory<br />

installed on 30GXN,R108,118-350 <strong>and</strong> associated modular<br />

units <strong>and</strong> 30HXA,C161-271 units. All other sizes use st<strong>and</strong>ard<br />

EXVs. The economizer is a brazed plate heat exchanger<br />

designed to improve chiller capacity <strong>and</strong> efficiency as well as<br />

providing compressor motor cooling. See Fig. 2. On 30GX<br />

chillers the economizer is active when any compressor is fully<br />

loaded. On 30HXA,C chillers the economizer is active all the<br />

time.<br />

Liquid refrigerant is supplied from the condenser to the<br />

top of the economizer. As the refrigerant passes through the<br />

economizer, its pressure is reduced to an intermediate level.<br />

Next, the refrigerant flows to the EXV which regulates flow to<br />

the cooler to maintain the discharge superheat setpoint.<br />

The increase in performance is achieved by diverting a<br />

small amount of liquid through a thermostatic expansion valve<br />

to a second circuit in the brazed-plate heat exchanger. This will<br />

further subcooling the liquid in the first circuit as the refrigerant<br />

flashes to vapor. This increase in subcooling provides additional<br />

capacity. Also, since the additional power required to accomplish<br />

this is minimal; the efficiency of the machine improves.<br />

The vapor that flashes leaves the top of the economizer where<br />

it passes to the compressor <strong>and</strong> is used to provide motor cooling.<br />

After passing over the motor windings, the refrigerant<br />

reenters the cycle at an intermediate port in the compression<br />

cycle.<br />

MOTOR COOLING<br />

SOLENOID<br />

TXV<br />

BULB<br />

TXV<br />

SOLENOID<br />

(30GXN,R ONLY)<br />

BRAZED PLATE<br />

ECONOMIZER<br />

Fig. 2 — Brazed Plate Economizer