steam jet ejector - Main Press

steam jet ejector - Main Press

steam jet ejector - Main Press

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Can a<br />

<strong>steam</strong> <strong>jet</strong> <strong>ejector</strong><br />

fit your vacuum process?<br />

by Frank Moerman, MSc., EHEDG Belgium and Nico Desanghere, MSc., Sterling SIHI<br />

Vacuum is widely applied in the<br />

chemical and food processing<br />

industry, because it permits to<br />

perform processes that cannot<br />

otherwise be done under atmospheric<br />

conditions.<br />

The most well-known sub-atmospheric<br />

application is vacuum distilation,<br />

where vacuum is used to lower the<br />

boiling point of a solvent or other chemical<br />

compound in order to perform a separation<br />

or purification of a high-boiling-point or<br />

thermal sensitive product with minimal input<br />

of heat. Vacuum processing is the solution<br />

for the increasing high-purity requirements<br />

for a growing number of materials in a large<br />

variety of applications. The costs of rejected,<br />

off-specification product and the rising energy<br />

costs are the main incentives to apply vacuum<br />

as a process aid.<br />

Applications in the food and<br />

chemical industry<br />

Other vacuum applications in the chemical<br />

industry are vacuum filtration, vacuum drying,<br />

vacuum evaporation, evaporative cooling,<br />

degassing, etc. Common vacuum applications<br />

in the food industry are given in Table 1.<br />

Keep up your vacuum with a<br />

<strong>steam</strong> <strong>jet</strong> <strong>ejector</strong><br />

Frequently, food and chemical plants find<br />

it less costly to obtain vacuum by means of<br />

<strong>steam</strong> <strong>jet</strong> <strong>ejector</strong>s. Especially the chemical<br />

industry makes largely use of <strong>steam</strong> <strong>jet</strong> <strong>ejector</strong>s<br />

to generate the vacuum required in many<br />

distillation processes. Table 2 gives an overview<br />

of some advantages and disadvantages<br />

of <strong>steam</strong> <strong>jet</strong> <strong>ejector</strong>s.<br />

Steam <strong>jet</strong> <strong>ejector</strong>s (usually multi-stage) are<br />

especially used for wet processes that require<br />

vacuum levels ranging from 15 mbar down<br />

to 0.1 mbar vacuum absolute. Water ring<br />

pumps are not capable to generate such a deep<br />

vacuum. Moreover, when <strong>steam</strong> <strong>jet</strong> <strong>ejector</strong>s<br />

are used to produce the required vacuum for<br />

distillation, evaporation or drying processes,<br />

the same <strong>steam</strong> <strong>ejector</strong>s can act as condenser<br />

for the water or solvent vapours drawn from<br />

these processes along with the air. A cold wall<br />

vapour condenser upstream of the <strong>steam</strong> <strong>jet</strong><br />

<strong>ejector</strong> may not be required, except where a<br />

engineeringnet.be<br />

PrOcess tecHNOlOGY<br />

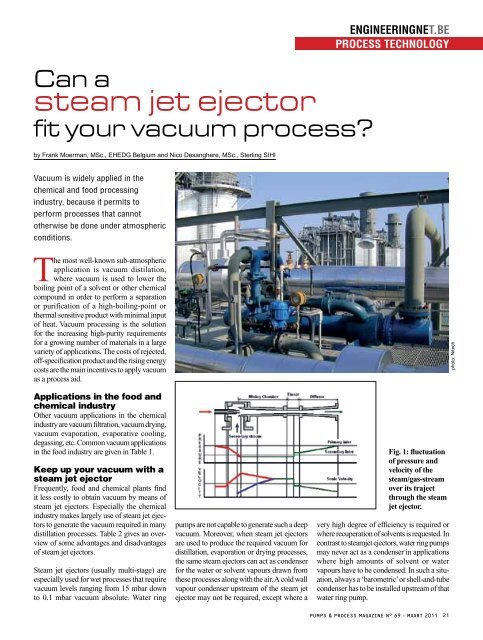

Fig. 1: fluctuation<br />

of pressure and<br />

velocity of the<br />

<strong>steam</strong>/gas-stream<br />

over its traject<br />

through the <strong>steam</strong><br />

<strong>jet</strong> <strong>ejector</strong>.<br />

very high degree of efficiency is required or<br />

where recuperation of solvents is requested. In<br />

contrast to <strong>steam</strong><strong>jet</strong> <strong>ejector</strong>s, water ring pumps<br />

may never act as a condenser in applications<br />

where high amounts of solvent or water<br />

vapours have to be condensed. In such a situation,<br />

always a ‘barometric’ or shell-and-tube<br />

condenser has to be installed upstream of that<br />

water ring pump.<br />

PUMPS & PROCESS MAGAZINE N° 69 - MAARt 2011 21<br />

photo: Nitech

Application Vacuum Absolute<br />

(mbar)<br />

Function<br />

engineeringnet.be<br />

PrOcess tecHNOlOGY<br />

‘Sous-vide’ cooking 50 - 250 To preserve the freshness and nutritional quality of the<br />

minimal processed food.<br />

Evisceration (poultry, fish, etc.) 100 - 150 To remove the bowels.<br />

De-aeration of vegetable oil<br />

50<br />

To remove oxygen that may oxidize unsaturated fatty<br />

acids.<br />

Deodorization of vegetable oil<br />

1 - 3<br />

To strip compounds that affect flavour, odour, stability and<br />

colour from the vegetable oil.<br />

Fractional distillation of vegetable oil<br />

Fractional distillation of essential oils<br />

10<br />

10<br />

To separate fatty acids or their esters from edible oils.<br />

Isolation of flavours and fragrances that otherwise may<br />

decompose and polymerize in the presence of to much<br />

heat.<br />

Freezing drying 20 - 50 Applied to prolong the shelf life of food and to maintain<br />

the basic nutrients in herbs, spices, coffee, fruit, vegetables,<br />

etc.<br />

UHT treatment - vacuum flash cooling of<br />

milk<br />

50 - 100 Milk is heated up to 140-145°C in as few as 3-5 s, contained<br />

in a holding tube for a few seconds, and then fastly<br />

cooled down to 75-80°C due to evaporative cooling as a<br />

consequence of a sudden reduction in pressure.<br />

Vacuum filtration (e.g. yeast) 300 - 600 On a rotary dum dryer a filter cake of yeast can be<br />

sucked dry by means of vacuum.<br />

Vacuum drying 20 - 50 (begin)<br />

1 - 4 (end)<br />

Water evaporates more quickly from food under vacuum.<br />

By vacuum drying, food can become crispy, puffed and<br />

may have a stable colour. Vacuum drying is biologically<br />

desirable since some enzymes that cause oxidation of<br />

food become active during normal air drying. These<br />

enzymes do not appear to be active under vacuum drying<br />

conditions. The speed and the fact that it happens at room<br />

temperature guarantees that taste, colour and nutritional<br />

value of the food are preserved. Also the fibers are fully<br />

preserved, so after reconstitution with water, vacuum dried<br />

fruit and vegetables will reproduce the original texture of<br />

the fresh fruit and vegetables. The drying process can be<br />

accelerated when assisted with micro-wave heating.<br />

Vacuum evaporation of milk 50 To concentrate heat-sensitive products (milk, sugar juices,<br />

etc.) that are prone to discolouration and formation of<br />

cooking favours under the impact of heat.<br />

De-aeration of water 50 Removal of air of the process water used in the preparation<br />

of soft drinks, sparkling and mineral water.<br />

Bottling of beer, soft drinks, mineral and<br />

sparkling water<br />

Vacuum packaging of food in plastic<br />

bags<br />

Modified atmospheric packaging 100<br />

(to remove the air)<br />

50 - 60 Removal of air (oxygen) and dust particles from the bottles<br />

to fill.<br />

100 To remove oxygen that may impair the nutritional quality<br />

by oxidation and that may promote microbial growth of<br />

spoiling bacteria and food pathogens.<br />

In modified atmospheric packaging, the air is first removed<br />

from the packaging by means of vacuum, to be finally<br />

replaced by a modified atmosphere.<br />

Table 1: vacuum applications in the food industry (Note: with vacuum absolute, we allude to the cacuum pressure measure relative to absolute perfect zero vacuum).<br />

How a <strong>steam</strong> <strong>jet</strong> <strong>ejector</strong><br />

works<br />

A <strong>steam</strong> <strong>jet</strong> <strong>ejector</strong> is in fact based on the<br />

principles of a water aspirator, that produces<br />

a vacuum by means of a venturi-effect and<br />

which is the oldest known method of vacuum<br />

generation. In a <strong>steam</strong> <strong>jet</strong> <strong>ejector</strong>, however, the<br />

water is replaced by <strong>steam</strong> as motive fluid.<br />

The motive <strong>steam</strong> fluid is expanded, after<br />

passing through a motive nozzle, where the<br />

pressure energy is transformed into kinetic<br />

energy. This energy stream impinges with<br />

and withdraws gases, air and water vapour<br />

from an application where a sub-atmospheric<br />

pressure (vacuum) must be established or<br />

maintained. The <strong>steam</strong> vapour accelerates into<br />

the inlet cone of the mixing nozzle. After passing<br />

through the throat of the mixing nozzle,<br />

into the diffuser, the kinetic energy of the<br />

mixed vapour stream is gradually converted<br />

back into potential energy, i.e. the medium is<br />

PUMPS & PROCESS MAGAZINE N° 69 - MAARt 2011 23

engineeringnet.be<br />

PrOcess tecHNOlOGY<br />

Fig. 2: three-stage <strong>steam</strong> <strong>jet</strong> <strong>ejector</strong> with<br />

two barometric intercondensers and one<br />

barometric aftercondenser.<br />

compressed to a higher discharge pressure.<br />

Fig. 1 demonstrates how the pressure and<br />

24<br />

Steam-<strong>jet</strong><br />

type<br />

1-stage<br />

2-stage<br />

3-stage<br />

4-stage<br />

Max.<br />

absolute<br />

vacuum<br />

(mbar)<br />

66<br />

5-15<br />

1-1.5<br />

0.1-0.3<br />

PUMPS & PROCESS MAGAZINE N° 69 - MAARt 2011<br />

velocity of the <strong>steam</strong>/<br />

gas-stream fluctuates<br />

over its traject through<br />

the <strong>steam</strong> <strong>jet</strong> <strong>ejector</strong>.<br />

Basic<br />

components<br />

of a <strong>steam</strong> <strong>jet</strong><br />

<strong>ejector</strong><br />

A single stage <strong>steam</strong><br />

<strong>ejector</strong> can produce<br />

only a limited vacuum<br />

(cfr. Table 2). Multistage<br />

<strong>steam</strong> <strong>ejector</strong>s<br />

(Fig. 2) are used when<br />

an application requires<br />

a pressure lower than<br />

what single-stage <strong>ejector</strong>s<br />

can develop, as the<br />

first can develop a greater suction pressure.<br />

With more stages added to the system, the<br />

pressure of the first stage becomes lesser<br />

and lesser, generating a deeper vacuum. The<br />

<strong>ejector</strong> which the entrained gases enter first,<br />

is called the first stage and subsequent stages<br />

Advantages Disadvantages<br />

- High achievable vacuum<br />

- High suction capacities and gas flow<br />

- Controlable over a wide range of vacuum<br />

and flow rates<br />

- Excellent to handle condensable corrosive<br />

and contaminated loads<br />

- Excellent to handle liquid slugs and solid<br />

particles<br />

- Reliable and robust in arduous and<br />

corrosive conditions<br />

- Simple design<br />

- Designed in many materials of construction<br />

- Mountable in any position<br />

- Low investment cost<br />

- No moving parts, less failure risk<br />

- Less susceptible to wear, and trouble-freeoperation<br />

- Long life-span<br />

- Simple repair & maintenance<br />

- No heat emission<br />

Table 2: advantages and disadvantages of <strong>steam</strong> <strong>jet</strong> <strong>ejector</strong>s.<br />

are numbered in succession.<br />

It is desirable to connect a condenser to<br />

the discharge of each <strong>steam</strong> <strong>jet</strong> <strong>ejector</strong> to<br />

bring all <strong>steam</strong> and condensable gases to<br />

the liquid state, reducing the load to the succeeding<br />

<strong>ejector</strong> stage and thus imposing on<br />

subsequent stages the work of compressing<br />

only those gases that are non-condensable.<br />

The condensers so em-ployed are known as<br />

intercondensers. A condenser connected to the<br />

diffuser dis-charge of the final stage is known<br />

as an aftercondenser, that is used to prevent the<br />

discharge of motive <strong>steam</strong> and condensable<br />

process vapours into atmosphere.<br />

An intercondenser operates at pressures<br />

less than atmospheric (under vacuum). It<br />

is therefore necessary to provide means for<br />

draining the mixture of condensing water<br />

and condensed <strong>steam</strong>/condensable vapours<br />

from a barometric intercondenser, or the<br />

condensed <strong>steam</strong>/condensable vapours only<br />

from a shell-and-tube inter-condenser. The<br />

non-condensable vapours are withdrawn from<br />

the top of each intercondenser by the vacuum<br />

of the subsequent <strong>steam</strong> <strong>ejector</strong>. The after-<br />

- Consumption of large amounts of <strong>steam</strong> as<br />

pressurized motive fluid<br />

- High energy consumption<br />

- Low thermal efficiency<br />

- Requires a <strong>steam</strong> infrastructure<br />

- Need for high quality <strong>steam</strong> produced from<br />

soft-demineralised water<br />

- Steam must be dry or should have less than<br />

2% moisture, because wet <strong>steam</strong> may cause<br />

the <strong>ejector</strong> vacuum to break or fluctuate, and<br />

can erode the nozzle and diffusers.<br />

- Needs inter-condensers and after-condensed<br />

and large amounts of cooling fluid to<br />

condense the mixture of motive and process<br />

vapour<br />

- Contamination of the motive fluid<br />

- Large amounts of contaminated <strong>steam</strong> condensate<br />

(waste water)<br />

- Load specific and very sensitive to variations<br />

in process conditions and pressure<br />

- Noisy, requires silencers or sound insulation

condenser operates at atmospheric<br />

pressure and is provided<br />

with a vent to finally allow air<br />

and non-condensable gases to<br />

escape in the atmosphere.<br />

‘Barometric’<br />

condensers<br />

A ‘barometric condenser’ (also<br />

called direct contact condenser)<br />

is a vertical vessel where<br />

withdrawn process vapours are<br />

cooled and condensed by direct<br />

contact with downward flowing<br />

cold water injected into the top<br />

of the vessel. Since the operating<br />

pressure of the condenser<br />

is sub-atmospheric (under<br />

vacuum), collected condensate<br />

(effluent cooling water and condensed <strong>steam</strong>/<br />

vapours) must be continuously removed. That<br />

condensate is normally dropped into a receiver<br />

tank that is often vented to atmosphere<br />

or a low pressure vent system. This creates<br />

a situation where the condensate is under<br />

vacuum in the condenser and is trying to<br />

move toward the receiver tank that is under<br />

positive pressure. To overcome this pressure<br />

differential, the condenser must be located<br />

higher than the receiver tank (the bottom of<br />

the condenser should be at least 10.4 meters<br />

above the ground) to create a tall ‘barometric<br />

leg’ (10.4 m long pipe) in which a static<br />

column of liquid balances the atmospheric<br />

pressure. The condensate must flow by gravity<br />

through this long sealed vertical tail pipe into<br />

Fig. 3: if tail pipe must change in direction,<br />

it should form at least a 45° angle<br />

from the horizontal plane; the horizontal<br />

piping (right drawing) is vulnerable to<br />

gas accumulation.<br />

a ‘hot-well’ (drainage basin provided with an<br />

overflow or pump) or a sealed condensate tank<br />

(provided with fluid-level control and condensate<br />

pump). The ‘barometric leg’ allows the<br />

effluent coolant and condensed vapours in the<br />

barometric condenser to exit no matter what<br />

its vacuum is, finally preventing the condenser<br />

from flooding under normal operation.<br />

In the receiver tank, the tail pipe must be<br />

submerged enough (not less than 28 cm). If<br />

this seal is broken, air will be drawn into the<br />

engineeringnet.be<br />

PrOcess tecHNOlOGY<br />

tailpipe, increasing the risk<br />

for flooding the condenser<br />

and hence affecting the<br />

performance of the downstream<br />

vacuum source and<br />

the upstream vacuum process.<br />

The drainage lines or<br />

tailpipes should be preferably<br />

installed vertically.<br />

Horizontal drain leg runs are<br />

not recommended, because<br />

they are susceptible to gas<br />

pockets. The mixture of<br />

cooling water plus condensed<br />

<strong>steam</strong>/condensable<br />

vapours always contain air<br />

or other non-condensable<br />

gases which cling to upper<br />

pipe surfaces. All types of<br />

pipe contain a certain amount of internal<br />

roughness and, because of this, gases tend to<br />

start clinging and building up in the smallest<br />

crevice. In addition, every flanged joint has<br />

a slight crack where a gasket is located, thus<br />

permitting another place for gases to collect.<br />

As these gases accumulate, they form tiny<br />

bubbles, growing into larger ones that eventually<br />

become big enough to partially or completely<br />

block off piping at that point. In that<br />

case, the condensate cannot flow downwards<br />

and soon its level rises, flooding the condenser.<br />

If piping changes direction, it must form at<br />

least a 45° angle from the horizontal (Fig. 3).<br />

With this amount of sloping, gases will either<br />

slide back up the pipe or continue downward<br />

with the thrust of the flowing water. The 45°<br />

Fig. 4: (a) with barometric condensers, it is important to note that condensate is splashing down the barometric walls and could run<br />

down the vapour inlet and back into the upstream vacuum process, unless the inlet is protected by a dam or series of elbows; (b)<br />

Degradation of the absolute vacuum pressure of an upstream process due to the pooling of liquid in pockets located in the vapour<br />

inlet or outlet piping. Pocket-free designs, however, may maintain the required absolute vacuum pressures.<br />

PUMPS & PROCESS MAGAZINE N° 69 - MAARt 2011 25

end may only installed at no less than 5 pipe diameters away from the<br />

condenser outlet flange. Where there is insufficient height to construct<br />

a proper barometric leg, a low-level, condensate-removal system can<br />

be added. This consists of a receiver equipped with a level controller<br />

and a condensate pump. As a condensate pump removes condensate at<br />

a constant rate, a mechanical level controller opens and closes a valve,<br />

to control the flow of cooling water to the condenser. However, if either<br />

pump or controller fails, there is a risk of flooding the vacuum system.<br />

Direct-contact condensers are easily to design, relatively inexpensive,<br />

and make multi-stage <strong>steam</strong> <strong>jet</strong> <strong>ejector</strong> designs less vulnerable to<br />

damage or fouling resulting from carryover of entrained solids. The<br />

major disadvantage of direct contact condensers is the large quantity<br />

of water that passes through once and goes to disposal, increasing the<br />

cost of wastewater and the environmental impact.<br />

Shell-and-tube condensers<br />

Surface-type condensers (that can be provided with supplementary<br />

mechanical refrigeration) are more complex and more expensive;<br />

but the amount of waste water to be treated decreases and valuable<br />

compounds can be recycled. In the case that a shell-and-tube surface<br />

condenser is used, this condenser must also be installed to allow for<br />

complete condensate drainage. The condensate may not flood the<br />

lower tubes of the condenser, otherwise they will not be able to remove<br />

heat effectively.<br />

Measures to protect the upstream process<br />

With barometric condensers, it is important to note that condensate is<br />

splashing down the barometric walls and could run down the vapour<br />

inlet and back into the vacuum process equipment, unless the inlet is<br />

protected by a dam or series of elbows (Fig. 4a).<br />

Condensable vapours flowing in the inlet or outlet vapour pipeline will<br />

naturally condense since the pipe is usually cooler than the saturation<br />

temperature of the vapour it contains. Vapour piping entering and<br />

leaving a barometric condenser (or a shell-and-tube condenser) may<br />

not contain any pockets (Fig. 4b) where this liquid can accumulate.<br />

The liquid pooling in these pockets, will completely seal off the line,<br />

which finally results in a downgrading of the vacuum. The absolute<br />

vacuum pressure up-stream of a pocket will rise dramatically.