Wire Rope Hoists _ Operating and Maintenance ... - STAHL-POLSKA

Wire Rope Hoists _ Operating and Maintenance ... - STAHL-POLSKA

Wire Rope Hoists _ Operating and Maintenance ... - STAHL-POLSKA

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

6 Inspection <strong>and</strong> maintenance<br />

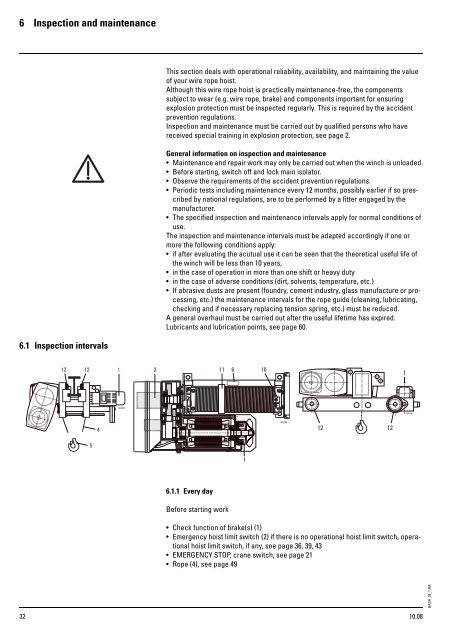

6.1 Inspection intervals<br />

32<br />

12<br />

12<br />

5<br />

4<br />

W0789<br />

2<br />

This section deals with operational reliability, availability, <strong>and</strong> maintaining the value<br />

of your wire rope hoist.<br />

Although this wire rope hoist is practically maintenance-free, the components<br />

subject to wear (e.g. wire rope, brake) <strong>and</strong> components important for ensuring<br />

explosion protection must be inspected regularly. This is required by the accident<br />

prevention regulations.<br />

Inspection <strong>and</strong> maintenance must be carried out by qualified persons who have<br />

received special training in explosion protection, see page 2.<br />

General information on inspection <strong>and</strong> maintenance<br />

<strong>Maintenance</strong> <strong>and</strong> repair work may only be carried out when the winch is unloaded.<br />

Before starting, switch off <strong>and</strong> lock main isolator.<br />

Observe the requirements of the accident prevention regulations.<br />

Periodic tests including maintenance every 12 months, possibly earlier if so prescribed<br />

by national regulations, are to be performed by a fitter engaged by the<br />

manufacturer.<br />

The specified inspection <strong>and</strong> maintenance intervals apply for normal conditions of<br />

use.<br />

The inspection <strong>and</strong> maintenance intervals must be adapted accordingly if one or<br />

more the following conditions apply:<br />

if after evaluating the acutual use it can be seen that the theoretical useful life of<br />

the winch will be less than 10 years,<br />

in the case of operation in more than one shift or heavy duty<br />

in the case of adverse conditions (dirt, solvents, temperature, etc.)<br />

If abrasive dusts are present (foundry, cement industry, glass manufacture or processing,<br />

etc.) the maintenance intervals for the rope guide (cleaning, lubricating,<br />

checking <strong>and</strong> if necessary replacing tension spring, etc.) must be reduced.<br />

A general overhaul must be carried out after the useful lifetime has expired.<br />

Lubricants <strong>and</strong> lubrication points, see page 60.<br />

6.1.1 Every day<br />

Before starting work<br />

11 6 10<br />

1<br />

W0790<br />

Check function of brake(s) (1)<br />

Emergency hoist limit switch (2) if there is no operational hoist limit switch, operational<br />

hoist limit switch, if any, see page 36, 39, 43<br />

EMERGENCY STOP, crane switch, see page 21<br />

<strong>Rope</strong> (4), see page 49<br />

12<br />

12<br />

1<br />

W0791<br />

10.08<br />

BASH_02_1.FM