RADIANT HEATING WITH INFRARED - Watlow

RADIANT HEATING WITH INFRARED - Watlow

RADIANT HEATING WITH INFRARED - Watlow

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Note: The spacing between source<br />

and load can also affect uniformity.<br />

Generally, the closer the heater is to<br />

the load, the more pronounced will<br />

be the effects of heater nonuniformity.<br />

Increased distance allows<br />

the radiant energy to “spread” and<br />

become less focused, but at the<br />

possible loss of efficiency due to<br />

greater edge losses.<br />

32<br />

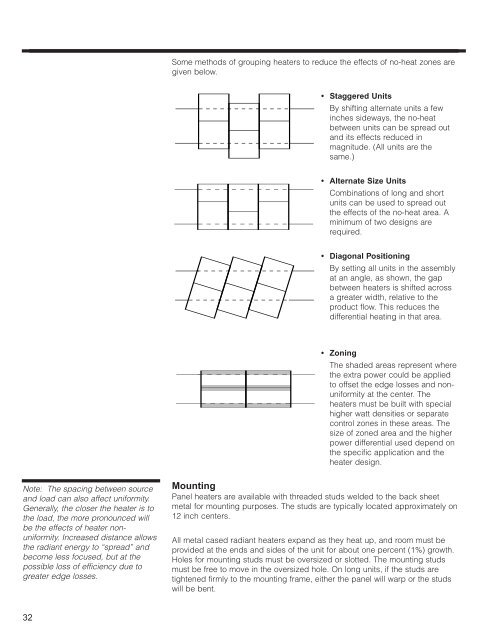

Some methods of grouping heaters to reduce the effects of no-heat zones are<br />

given below.<br />

• Staggered Units<br />

By shifting alternate units a few<br />

inches sideways, the no-heat<br />

between units can be spread out<br />

and its effects reduced in<br />

magnitude. (All units are the<br />

same.)<br />

• Alternate Size Units<br />

Combinations of long and short<br />

units can be used to spread out<br />

the effects of the no-heat area. A<br />

minimum of two designs are<br />

required.<br />

• Diagonal Positioning<br />

By setting all units in the assembly<br />

at an angle, as shown, the gap<br />

between heaters is shifted across<br />

a greater width, relative to the<br />

product flow. This reduces the<br />

differential heating in that area.<br />

• Zoning<br />

The shaded areas represent where<br />

the extra power could be applied<br />

to offset the edge losses and nonuniformity<br />

at the center. The<br />

heaters must be built with special<br />

higher watt densities or separate<br />

control zones in these areas. The<br />

size of zoned area and the higher<br />

power differential used depend on<br />

the specific application and the<br />

heater design.<br />

Mounting<br />

Panel heaters are available with threaded studs welded to the back sheet<br />

metal for mounting purposes. The studs are typically located approximately on<br />

12 inch centers.<br />

All metal cased radiant heaters expand as they heat up, and room must be<br />

provided at the ends and sides of the unit for about one percent (1%) growth.<br />

Holes for mounting studs must be oversized or slotted. The mounting studs<br />

must be free to move in the oversized hole. On long units, if the studs are<br />

tightened firmly to the mounting frame, either the panel will warp or the studs<br />

will be bent.