Important Placement Instructions Enclosed See Lifting - Haas ...

Important Placement Instructions Enclosed See Lifting - Haas ...

Important Placement Instructions Enclosed See Lifting - Haas ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

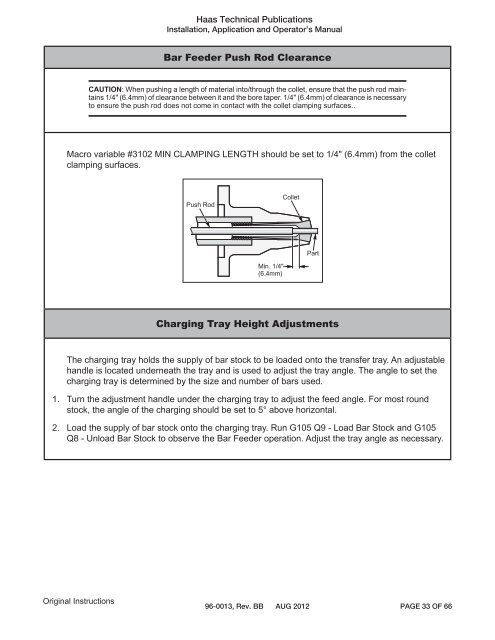

Bar Feeder Push Rod Clearance<br />

CAUTION: When pushing a length of material into/through the collet, ensure that the push rod maintains<br />

1/4" (6.4mm) of clearance between it and the bore taper. 1/4" (6.4mm) of clearance is necessary<br />

to ensure the push rod does not come in contact with the collet clamping surfaces..<br />

Macro variable #3102 MIN CLAMPING LENGTH should be set to 1/4" (6.4mm) from the collet<br />

clamping surfaces.<br />

Push Rod<br />

Min. 1/4"<br />

(6.4mm)<br />

Collet<br />

Part<br />

Charging Tray Height Adjustments<br />

The charging tray holds the supply of bar stock to be loaded onto the transfer tray. An adjustable<br />

handle is located underneath the tray and is used to adjust the tray angle. The angle to set the<br />

charging tray is determined by the size and number of bars used.<br />

1. Turn the adjustment handle under the charging tray to adjust the feed angle. For most round<br />

stock, the angle of the charging should be set to 5° above horizontal.<br />

2. Load the supply of bar stock onto the charging tray. Run G105 Q9 - Load Bar Stock and G105<br />

Q8 - Unload Bar Stock to observe the Bar Feeder operation. Adjust the tray angle as necessary.<br />

Original <strong>Instructions</strong><br />

<strong>Haas</strong> Technical Publications<br />

Installation, Application and Operator’s Manual<br />

96-0013, Rev. BB Aug 2012<br />

PAgE 33 OF 66