Instructions for web - Gifkins Dovetail Jig

Instructions for web - Gifkins Dovetail Jig

Instructions for web - Gifkins Dovetail Jig

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

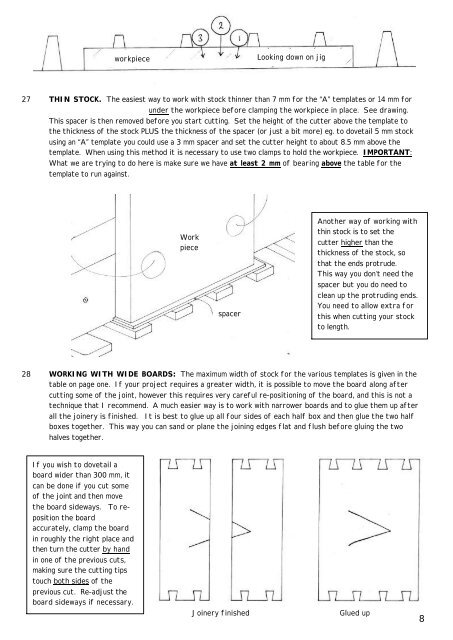

27 THIN STOCK. The easiest way to work with stock thinner than 7 mm <strong>for</strong> the “A” templates or 14 mm <strong>for</strong><br />

under the workpiece be<strong>for</strong>e clamping the workpiece in place. See drawing.<br />

This spacer is then removed be<strong>for</strong>e you start cutting. Set the height of the cutter above the template to<br />

the thickness of the stock PLUS the thickness of the spacer (or just a bit more) eg. to dovetail 5 mm stock<br />

using an “A” template you could use a 3 mm spacer and set the cutter height to about 8.5 mm above the<br />

template. When using this method it is necessary to use two clamps to hold the workpiece. IMPORTANT:<br />

What we are trying to do here is make sure we have at least 2 mm of bearing above the table <strong>for</strong> the<br />

template to run against.<br />

28 WORKING WITH WIDE BOARDS: The maximum width of stock <strong>for</strong> the various templates is given in the<br />

table on page one. If your project requires a greater width, it is possible to move the board along after<br />

cutting some of the joint, however this requires very careful re-positioning of the board, and this is not a<br />

technique that I recommend. A much easier way is to work with narrower boards and to glue them up after<br />

all the joinery is finished. It is best to glue up all four sides of each half box and then glue the two half<br />

boxes together. This way you can sand or plane the joining edges flat and flush be<strong>for</strong>e gluing the two<br />

halves together.<br />

If you wish to dovetail a<br />

board wider than 300 mm, it<br />

can be done if you cut some<br />

of the joint and then move<br />

the board sideways. To re-<br />

position the board<br />

accurately, clamp the board<br />

workpiece<br />

in roughly the right place and<br />

then turn the cutter by hand<br />

in one of the previous cuts,<br />

making sure the cutting tips<br />

touch both sides of the<br />

previous cut. Re-adjust the<br />

board sideways if necessary.<br />

Work<br />

piece<br />

spacer<br />

Looking down on jig<br />

Another way of working with<br />

thin stock is to set the<br />

cutter higher than the<br />

thickness of the stock, so<br />

that the ends protrude.<br />

This way you don’t need the<br />

spacer but you do need to<br />

clean up the protruding ends.<br />

You need to allow extra <strong>for</strong><br />

this when cutting your stock<br />

to length.<br />

Joinery finished Glued up<br />

8