Minor millets in South Asia: learnings from IFAD-NUS project in India ...

Minor millets in South Asia: learnings from IFAD-NUS project in India ...

Minor millets in South Asia: learnings from IFAD-NUS project in India ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

30 m<strong>in</strong>or <strong>millets</strong> <strong>in</strong> south asia<br />

and INR 2,733 <strong>in</strong> the case of pure f<strong>in</strong>ger millet crop. In the case of little millet<br />

and foxtail millet, the additional<br />

<strong>in</strong>come generated <strong>from</strong> improved<br />

agronomic package of practices<br />

were 53% and 40.8%, respectively.<br />

In actual terms, the additional<br />

average net <strong>in</strong>come generated<br />

by the improved practices <strong>in</strong><br />

the little millet-based <strong>in</strong>tercrop<br />

was INR 4,605/ha, while the<br />

same <strong>in</strong> the foxtail millet-based<br />

<strong>in</strong>tercrop was INR 3,512/ha. In<br />

terms of strengthen<strong>in</strong>g of food<br />

security aris<strong>in</strong>g <strong>from</strong> <strong>in</strong>creased<br />

nutritious millet gra<strong>in</strong> productivity<br />

contributed by improved agronomic<br />

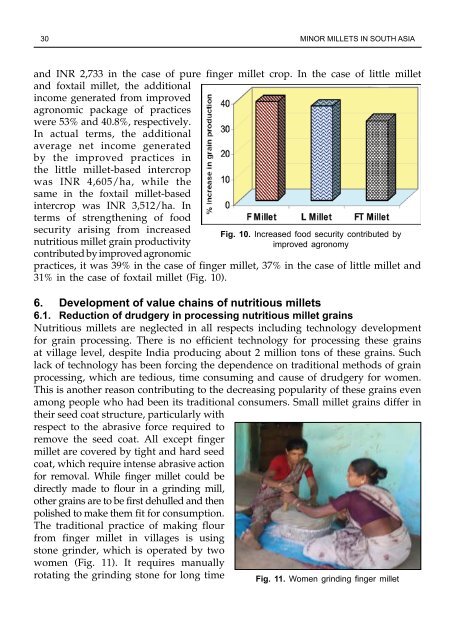

Fig. 10. <strong>in</strong>creased food security contributed by<br />

improved agronomy<br />

practices, it was 39% <strong>in</strong> the case of f<strong>in</strong>ger millet, 37% <strong>in</strong> the case of little millet and<br />

31% <strong>in</strong> the case of foxtail millet (Fig. 10).<br />

6. Development of value cha<strong>in</strong>s of nutritious <strong>millets</strong><br />

6.1. Reduction of drudgery <strong>in</strong> process<strong>in</strong>g nutritious millet gra<strong>in</strong>s<br />

Nutritious <strong>millets</strong> are neglected <strong>in</strong> all respects <strong>in</strong>clud<strong>in</strong>g technology development<br />

for gra<strong>in</strong> process<strong>in</strong>g. There is no efficient technology for process<strong>in</strong>g these gra<strong>in</strong>s<br />

at village level, despite <strong>India</strong> produc<strong>in</strong>g about 2 million tons of these gra<strong>in</strong>s. Such<br />

lack of technology has been forc<strong>in</strong>g the dependence on traditional methods of gra<strong>in</strong><br />

process<strong>in</strong>g, which are tedious, time consum<strong>in</strong>g and cause of drudgery for women.<br />

This is another reason contribut<strong>in</strong>g to the decreas<strong>in</strong>g popularity of these gra<strong>in</strong>s even<br />

among people who had been its traditional consumers. Small millet gra<strong>in</strong>s differ <strong>in</strong><br />

their seed coat structure, particularly with<br />

respect to the abrasive force required to<br />

remove the seed coat. All except f<strong>in</strong>ger<br />

millet are covered by tight and hard seed<br />

coat, which require <strong>in</strong>tense abrasive action<br />

for removal. While f<strong>in</strong>ger millet could be<br />

directly made to flour <strong>in</strong> a gr<strong>in</strong>d<strong>in</strong>g mill,<br />

other gra<strong>in</strong>s are to be first dehulled and then<br />

polished to make them fit for consumption.<br />

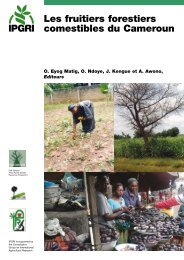

The traditional practice of mak<strong>in</strong>g flour<br />

<strong>from</strong> f<strong>in</strong>ger millet <strong>in</strong> villages is us<strong>in</strong>g<br />

stone gr<strong>in</strong>der, which is operated by two<br />

women (Fig. 11). It requires manually<br />

rotat<strong>in</strong>g the gr<strong>in</strong>d<strong>in</strong>g stone for long time Fig. 11. Women gr<strong>in</strong>d<strong>in</strong>g f<strong>in</strong>ger millet