You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

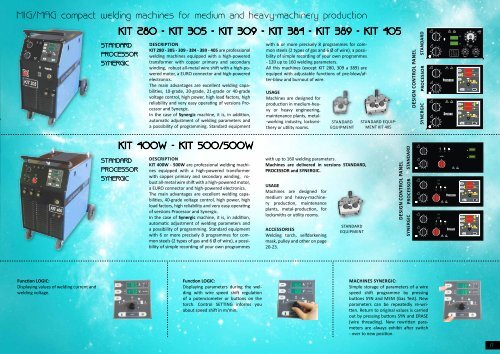

mIG/mAG compact welding machines for medium and heavy-machinery production<br />

Function LOGIC:<br />

Displaying values of welding current and<br />

welding voltage.<br />

KIt 280 - KIt 305 - KIt 309 - KIt 384 - KIt 389 - KIt 405<br />

StANDArD<br />

PrOCeSSOr<br />

SYNerGIC<br />

descrIptIon<br />

KIT 280 - 305 - 309 - 384 - 389 - 405 are professional<br />

welding machines equipped with a high-powered<br />

transformer with copper primary and secondary<br />

winding, robust all-metal wire shift with a high-powered<br />

motor, a EURO connector and high-powered<br />

electronics.<br />

The main advantages are excellent welding capabilities,<br />

10-grade, 20-grade, 21-grade or 40-grade<br />

voltage control, high power, high load factors, high<br />

reliability and very easy operating of versions Processor<br />

and Synergic.<br />

In the case of Synergic machine, it is, in addition,<br />

automatic adjustment of welding parameters and<br />

a possibility of programming. Standard equipment<br />

KIt 400W - KIt 500/500W<br />

StANDArD<br />

PrOCeSSOr<br />

SYNerGIC<br />

descrIptIon<br />

KIT 400W - 500W are professional welding machines<br />

equipped with a high-powered transformer<br />

with copper primary and secondary winding, robust<br />

all-metal wire shift with a high-powered motor,<br />

a EURO connector and high-powered electronics.<br />

The main advantages are excellent welding capabilities,<br />

40-grade voltage control, high power, high<br />

load factors, high reliability and very easy operating<br />

of versions Processor and Synergic.<br />

In the case of Synergic machine, it is, in addition,<br />

automatic adjustment of welding parameters and<br />

a possibility of programming. Standard equipment<br />

with 6 or more precisely 8 programmes for common<br />

steels (2 types of gas and 6 Ø of wire), a possibility<br />

of simple recording of your own programmes<br />

Function LOGIC:<br />

Displaying parameters during the welding<br />

with wire speed shift regulation<br />

of a potenciometer or buttons on the<br />

torch. Control SETTING informs you<br />

about speed shift in m/min.<br />

with 6 or more precisely 8 programmes for common<br />

steels (2 types of gas and 6 Ø of wire), a possibility<br />

of simple recording of your own programmes<br />

- 120 up to 160 welding parameters.<br />

All this machines (except KIT 280, 309 a 389) are<br />

equiped with adjustable functions of pre-blow/after-blow<br />

and burnout of wire.<br />

UsaGe<br />

Machines are designed for<br />

production in medium-heavy<br />

or heavy engineering,<br />

maintenance plants, metal-<br />

-working industry, locksmithery<br />

or utility rooms.<br />

with up to 160 welding parameters.<br />

Machines are delivered in versions STANDARD,<br />

PROCESSOR and SYNERGIC.<br />

UsaGe<br />

Machines are designed for<br />

medium and heavy-machinery<br />

production, maintenance<br />

plants, metal-production, for<br />

locksmiths or utility rooms.<br />

accessorIes<br />

Welding torch, selfdarkening<br />

mask, pulley and other on page<br />

20-23.<br />

STANDARD<br />

EQUIPMENT<br />

STANDARD<br />

EQUIPMENT<br />

STANDARD EQUIP-<br />

MENT KIT 405<br />

desIGn control panel<br />

synerGIc processor standard<br />

desIGn control panel<br />

synerGIc processor standard<br />

machInes synerGIc:<br />

Simple storage of parameters of a wire<br />

speed shift programme by pressing<br />

buttons SYN and MEM (Gas Test). New<br />

parameters can be repeatedly re-written.<br />

Return to original values is carried<br />

out by pressing buttons SYN and ERASE<br />

(wire threading). New rewritten parameters<br />

are always exhibit after switch<br />

- over to new position.<br />

17