You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

4<br />

Single phase undervoltage portable inverter machines for welding with stick electrode and tIG method<br />

new<br />

FéNIx 160 - 200<br />

Designed and<br />

manufactured<br />

in Kühtreiber<br />

descrIptIon<br />

FéNIx 160 - 200 are compact, portable low-voltage<br />

MMA and TIG welding machines. Design is based<br />

on inverter-microcontroller technology using a planar<br />

transformer.<br />

fénIx machines are designed with energy-saving<br />

inverter technology, high-level microprocessor by<br />

using planar transformer. Show excellent results<br />

either in normal operation or in use on generator<br />

and also on long extension cables. The ideal characteristic<br />

of arc ensures its excellent stability even<br />

if fluctuating voltage in connections or while using<br />

long network cable (up to 200 m length). Machine<br />

controls are integrated into the keyboard button,<br />

which increases the accuracy and reliability of the<br />

machine control.<br />

Further advantages of fénIx machine is high performance<br />

and efficiency, easy to understand controls<br />

and the possibility of connection of remote<br />

control.<br />

FÉNIX 160 - FÉNIX 200 - FÉNIX 200 PFC<br />

characterIstIcs and eQUIpment<br />

• May be used with power generator with min.<br />

output of 3.5 kVA (with A.V.R. feature).<br />

• Optional use of up to 200m (2.5mm 2 cross-section)<br />

extension cable.<br />

• Enables welding when network voltage drops<br />

by as much as 40% (from 140 V) using electrode<br />

1.6; 2.0; 2.5.<br />

• Connection of a remote control to regulate<br />

welding current<br />

• Thermal protection with light indicator<br />

• Undervoltage / over-voltage indicators<br />

• MMA Method<br />

o Function HOT START feature enables easier<br />

ignition of coated electrodes.<br />

o Function ANTI STICK feature prevents adhesion<br />

of coated electrode.<br />

o Function ARC FORCE feature ensures arc stability.<br />

o V.R.D. = feature = MMA safety system; 15 V at<br />

output terminals in resting state.<br />

o Function SOFT START MMA (prevents hair<br />

breakers).<br />

• TIG Method<br />

o Manual arc ignition using - LIFT ARC.<br />

o Function PULSE.<br />

o DOWN SLOPE (deceleration time on end current).<br />

o END CURRENT.<br />

FéNIx 200 PFC<br />

descrIptIon<br />

fénIx 200 PFC is a compacted, portable undervoltage<br />

welding machine for MMA and TIG welding,<br />

which is equipped with PFC (Power Factor Correction).<br />

fénIx is constructed by using energy-saving inverter<br />

microprocessor technology PFC highest levels<br />

with the using of a planar transformer, which<br />

modulates the input stream so that it has an almost<br />

ideal sinusoidal waveform, which provides up to<br />

92% efficiency of the machine.<br />

PFC technology ensures stable welding process<br />

with fluctuating voltage el. network, even when<br />

using long extension cords and use electric genera-<br />

tors, without any apparent difference in the arc.<br />

The machine is able to operate from 90 V in el. Network.<br />

FéNIx 200 PFC is able to work of the same<br />

protection from the network and to get against conventional<br />

welding machines up to 40% more power<br />

(eg where the machine ejects the fuse at 150 A,<br />

FéNIx 200 PFC welded without problems on current<br />

of 200 A).<br />

The machine has a function to limit the output current<br />

by which one can work with the machine in<br />

low protection in the network. fénIx pfc is predestined<br />

for use on generator, long extension cord and<br />

using the weak breakers.<br />

FéNIx 200 PFC provides excellent arc stability, simple<br />

and easy to understand controls, remote control<br />

options, performance and equipment.<br />

Machine controls are integrated into the keyboard<br />

button, which increases the accuracy and reliability<br />

of the machine control. Welding machine fénIx<br />

200 PFC is designed for the most demanding users.<br />

characterIstIcs and eQUIpment<br />

• May be used with power generator with min.<br />

output of 3.5 kVA (with A.V.R. feature).<br />

• Optional use of up to 200m (2.5mm 2 cross-section)<br />

extension cable.<br />

• It is possible to weld while 60% (from 90 V)<br />

voltage decline (even with continuos decline) in<br />

network - with electrode 1,6; 2,0; 2,5; 3,2; 4,0.<br />

• Connection of a remote control to regulate<br />

welding current.<br />

• Thermal protection with light indicator.<br />

• MMA Method<br />

o Function HOT START feature enables easier<br />

ignition of coated electrodes.<br />

o Function ANTI STICK feature prevents adhesion<br />

of coated electrode.<br />

o Function ARC FORCE feature ensures arc stability.<br />

o V.R.D. = feature = MMA safety system; 15 V at<br />

output terminals in resting state.<br />

o Function of limiting the output/input current<br />

to prevent loss of circuit breakers (option of<br />

simulation of any protection from 5 to 50 A).<br />

o Function SOFT START MMA (prevents hair<br />

breakers).<br />

• TIG Method<br />

o Manual arc ignition using - LIFT ARC.<br />

o Function PULSE.<br />

o DOWN SLOPE (deceleration time on end current).<br />

o END CURRENT.<br />

o Function to limit the output current.<br />

UsaGe<br />

High performance, excellent welding properties a<br />

ability to cope with 40 %, actually 60 % (FéNIx 200<br />

pfc) under voltage machines are ideal for use in assembly,<br />

in maintenance operations, repairs, heavy<br />

industry, but also for domestic use.<br />

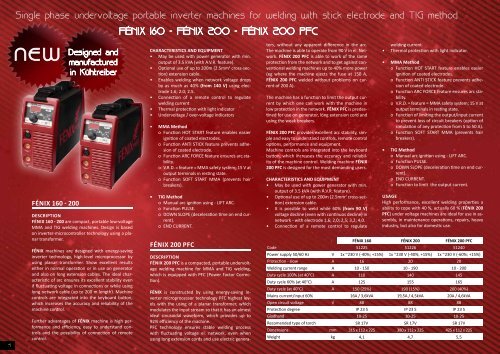

FéNIx 160 FéNIx 200 FéNIx 200 PFC<br />

Code 51225 51226 51240<br />

Power supply 50/60 Hz V 1x ~230 V (-40%; +15%) 1x ~230 V (-40%; +15%) 1x ~230 V (-60%; +15%)<br />

Protection - slow A 16 20 20<br />

Welding current range A 10 - 150 10 - 190 10 - 200<br />

Duty cycle 100% (at 40°C) A 110 140 145<br />

Duty cycle 60% (at 40°C) A 125 155 165<br />

Duty cycle (at 40°C) A 150 (25%) 190 (15%) 200 (40%)<br />

Mains current/input 60% 16A / 3,6kVA 19,5A / 4,5kVA 20A / 4,6kVA<br />

Open circuit voltage V 88 88 88<br />

Protection degree IP 23 S IP 23 S IP 23 S<br />

Gladhand 10-25 10-25 10-25<br />

Recomended type of torch SR 17V SR 17V SR 17V<br />

Dimensions mm 315 x 112 x 225 380 x 112 x 225 425 x 112 x 225<br />

Weight kg 4,1 4,7 5,5