You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

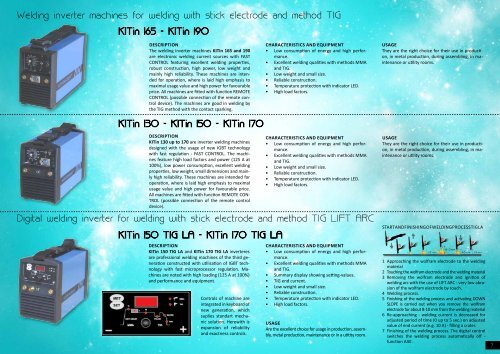

Welding inverter machines for welding with stick electrode and method tIG<br />

KItin 165 - KItin 190<br />

descrIptIon<br />

The welding inverter machines KITin 165 and 190<br />

are electronic welding current sources with FAST<br />

CONTROL featuring excellent welding properties,<br />

robust construction, high power, low weight and<br />

mainly high reliability. These machines are intended<br />

for operation, where is laid high emphasis to<br />

maximal usage value and high power for favourable<br />

price. All machines are fitted with function REMOTE<br />

CONTROL (possible connection of the remote control<br />

device). The machines are good in welding by<br />

the TIG method with the contact sparking.<br />

KItin 130 - KItin 150 - KItin 170<br />

descrIptIon<br />

KITin 130 up to 170 are inverter welding machines<br />

designed with the usage of new IGBT technology<br />

with fast regulation - FAST CONTROL. The machines<br />

feature high load factors and power (125 A at<br />

100%), low power consumption, excellent welding<br />

properties, low weight, small dimensions and mainly<br />

high reliability. These machines are intended for<br />

operation, where is laid high emphasis to maximal<br />

usage value and high power for favourable price.<br />

All machines are fitted with function REMOTE CON-<br />

TROL (possible connection of the remote control<br />

device).<br />

Digital welding inverter for welding with stick electrode and method tIG LIFt ArC<br />

KItin 150 tIG LA - KItin 170 tIG LA<br />

descrIptIon<br />

KITin 150 TIG LA and KITin 170 TIG LA inverteres<br />

are professional welding machines of the third generation<br />

constructed with utilisation of IGBT technology<br />

with fast microprocessor regulation. Machines<br />

are noted with high loading (125 A at 100%)<br />

and performance and equipment.<br />

Controls of machine are<br />

integrated in keyboard of<br />

new generation, which<br />

suplies standart mechanic<br />

solution. Herewith is<br />

expansion of reliability<br />

and exactness controls.<br />

characterIstIcs and eQUIpment<br />

• Low consumption of energy and high performance.<br />

• Excellent welding qualities with methods MMA<br />

and TIG.<br />

• Low weight and small size.<br />

• Reliable construction.<br />

• Temperature protection with indicator LED.<br />

• High load factors.<br />

characterIstIcs and eQUIpment<br />

• Low consumption of energy and high performance.<br />

• Excellent welding qualities with methods MMA<br />

and TIG.<br />

• Low weight and small size.<br />

• Reliable construction.<br />

• Temperature protection with indicator LED.<br />

• High load factors.<br />

characterIstIcs and eQUIpment<br />

• Low consumption of energy and high performance.<br />

• Excellent welding qualities with methods MMA<br />

and TIG.<br />

• Summary display showing setting-values.<br />

• TIG end current.<br />

• Low weight and small size.<br />

• Reliable construction.<br />

• Temperature protection with indicator LED.<br />

• High load factors.<br />

UsaGe<br />

Are the excellent choice for usage in production, assembly,<br />

metal production, maintenance or in a utitity room.<br />

UsaGe<br />

They are the right choice for their use in production,<br />

in metal production, during assembling, in maintenance<br />

or utility rooms.<br />

UsaGe<br />

They are the right choice for their use in production,<br />

in metal production, during assembling, in maintenance<br />

or utility rooms.<br />

START AND FINISHING OF WELDING PROCESS TIG LA<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

Approaching the wolfram electrode to the welding<br />

material<br />

Touching the wolfram electrode and the welding material<br />

Removing the wolfram electrode and ignition of<br />

welding arc with the use of LIFT ARC - very low abrasion<br />

of the wolfram electrode by touch.<br />

Welding process.<br />

Finishing of the welding process and activating DOWN<br />

SLOPE is carried out when you remove the wolfram<br />

electrode for about 8-10 mm from the welding material<br />

Re-approaching - welding current is decreased for<br />

adjusted period of time (0 up to 5 sec.) on adjusted<br />

value of end current (e.g. 10 A) - filling a crater.<br />

Finishing of the welding process. The digital control<br />

switches the welding process automatically off -<br />

function AAE.<br />

7