You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

8<br />

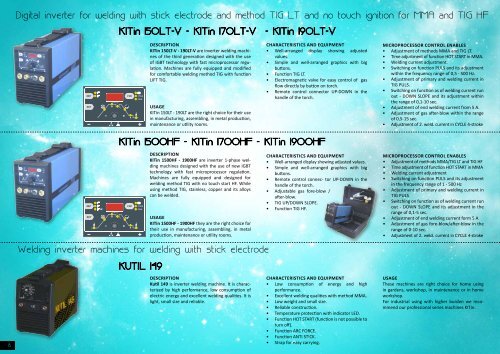

Digital inverter for welding with stick electrode and method tIG Lt and no touch ignition for mmA and tIG hF<br />

KItin 150Lt-V - KItin 170Lt-V - KItin 190Lt-V<br />

descrIptIon<br />

KITin 150LT-V - 190LT-V are inverter welding machines<br />

of the third generation designed with the use<br />

of IGBT technology with fast microprocessor regulation.<br />

Machines are fully equipped and modified<br />

for comfortable welding method TIG with function<br />

LIFT TIG.<br />

UsaGe<br />

KITin 150LT - 190LT are the right choice for their use<br />

in manufacturing, assembling, in metal production,<br />

maintenance or utility rooms.<br />

KItin 1500hF - KItin 1700hF - KItin 1900hF<br />

descrIptIon<br />

KITin 1500HF - 1900HF are inverter 1-phase welding<br />

machines designed with the use of new IGBT<br />

technology with fast microprocessor regulation.<br />

Machines are fully equipped and designed for<br />

welding method TIG with no touch start HF. While<br />

using method TIG, stainless, copper and its alloys<br />

can be welded.<br />

UsaGe<br />

KITin 1500HF - 1900HF they are the right choice for<br />

their use in manufacturing, assembling, in metal<br />

production, maintenance or utility rooms.<br />

Welding inverter machines for welding with stick electrode<br />

KUTIL 149<br />

descrIptIon<br />

Kutil 149 is inverter welding machine. It is characterized<br />

by high performance, low consumption of<br />

electric energy and excellent welding qualities. It is<br />

light, small size and reliable.<br />

characterIstIcs and eQUIpment<br />

• Well-arranged display showing adjusted<br />

values.<br />

• Simple and well-arranged graphics with big<br />

buttons.<br />

• Function TIG LT.<br />

• Electromagnetic valve for easy control of gas<br />

flow directly by button on torch.<br />

• Remote control connector UP-DOWN in the<br />

handle of the torch.<br />

characterIstIcs and eQUIpment<br />

• Well-arranged display showing adjusted values.<br />

• Simple and well-arranged graphics with big<br />

buttons.<br />

• Remote control connec- tor UP-DOWN in the<br />

handle of the torch.<br />

• Adjustable gas fore-blow /<br />

after-blow.<br />

• TIG UP/DOWN SLOPE.<br />

• Function TIG HF.<br />

characterIstIcs and eQUIpment<br />

• Low consumption of energy and high<br />

performance.<br />

• Excellent welding qualities with method MMA.<br />

• Low weight and small size.<br />

• Reliable construction.<br />

• Temperature protection with indicator LED.<br />

• Function HOT START (function is not possible to<br />

turn off).<br />

• Function ARC FORCE.<br />

• Function ANTI STICK.<br />

• Strap for easy carrying.<br />

mIcroprocessor control enables<br />

• Adjustment of methods MMA and TIG LT.<br />

• Time adjustment of function HOT START in MMA.<br />

• Welding current adjustment.<br />

• Switching on function PULS and its adjustment<br />

within the frequency range of 0,5 - 500 Hz.<br />

• Adjustment of primary and welding current in<br />

TIG PULS.<br />

• Switching on function as of welding current run<br />

out - DOWN SLOPE and its adjustment within<br />

the range of 0,1-10 sec.<br />

• Adjustment of end welding current from 5 A.<br />

• Adjustment of gas after-blow within the range<br />

of 0,5-15 sec.<br />

• Adjustment of 2. weld. current in CYCLE 4-stroke<br />

mIcroprocessor control enables<br />

• Adjustment of methods MMA/TIG LT and TIG HF<br />

• Time adjustment of function HOT START in MMA<br />

• Welding current adjustment<br />

• Switching on function PULS and its adjustment<br />

in the frequency range of 1 - 500 Hz<br />

• Adjustment of primary and welding current in<br />

TIG PULS<br />

• Switching on function as of welding current run<br />

out - DOWN SLOPE and its adjustment in the<br />

range of 0,1-5 sec.<br />

• Adjustment of end welding current form 5 A<br />

• Adjustment of gas fore-blow/after-blow in the<br />

range of 0-10 sec.<br />

• Adjustment of 2. weld. current in CYCLE 4-stroke<br />

UsaGe<br />

These machines are right choice for home using<br />

in gardens, workshop, in maintenance or in home<br />

workshop.<br />

For industrial using with higher burden we recommend<br />

our professional series machines KITin.