Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

18<br />

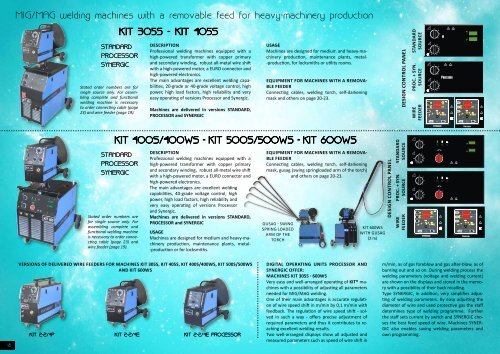

mIG/mAG welding machines with a removable feed for heavy-machinery production<br />

KIt 305S - KIt 405S<br />

StANDArD<br />

PrOCeSSOr<br />

SYNerGIC<br />

Stated order numbers are for<br />

single source only. For assembling<br />

complete and functional<br />

welding machine is necessary<br />

to order connecting cable (page<br />

23) and wire feeder (page 19).<br />

descrIptIon<br />

Professional welding machines equipped with a<br />

high-powered transformer with copper primary<br />

and secondary winding, robust all-metal wire shift<br />

with a high-powered motor, a EURO connector and<br />

high-powered electronics.<br />

The main advantages are excellent welding capabilities,<br />

20-grade or 40-grade voltage control, high<br />

power, high load factors, high reliability and very<br />

easy operating of versions Processor and Synergic.<br />

Machines are delivered in versions STANDARD,<br />

PROCESSOR and SYNERGIC<br />

KIt 400S/400WS - KIt 500S/500WS - KIt 600WS<br />

StANDArD<br />

PrOCeSSOr<br />

SYNerGIC<br />

Stated order numbers are<br />

for single source only. For<br />

assembling complete and<br />

functional welding machine<br />

is necessary to order connecting<br />

cable (page 23) and<br />

wire feeder (page 19).<br />

descrIptIon<br />

Professional welding machines equipped with a<br />

high-powered transformer with copper primary<br />

and secondary winding, robust all-metal wire shift<br />

with a high-powered motor, a EURO connector and<br />

high-powered electronics.<br />

The main advantages are excellent welding<br />

capabilities, 40-grade voltage control, high<br />

power, high load factors, high reliability and<br />

very easy operating of versions Processor<br />

and Synergic.<br />

Machines are delivered in versions STANDARD,<br />

PROCESSOR and SYNERGIC<br />

UsaGe<br />

Machines are designed for medium and heavy-machinery<br />

production, maintenance plants, metal-<br />

-production or for locksmiths.<br />

VERSIONS OF DELIVERED WIRE FEEDERS FOR MACHINES KIT 305S, KIT 405S, KIT 400S/400WS, KIT 500S/500WS<br />

AND KIT 600WS<br />

KIt 2-2/4P KIt 2-2/4e<br />

KIt 2-2/4e PrOCeSSOr<br />

UsaGe<br />

Machines are designed for medium and heavy-machinery<br />

production, maintenance plants, metal-<br />

-production, for locksmiths or utility rooms.<br />

eQUIpment for machInes WIth a removable<br />

feeder<br />

Connecting cables, welding torch, self-darkening<br />

mask and others on page 20-23.<br />

eQUIpment for machInes WIth a removable<br />

feeder<br />

Connecting cables, welding torch, self-darkening<br />

mask, gusag (swing springloaded arm of the torch)<br />

and others on page 20-23.<br />

GUSAG - SWING<br />

SPRING LOADED<br />

ARM OF THE<br />

TORCH<br />

dIGItal operatInG UnIts processor and<br />

synerGIc offer:<br />

MACHINES KIT 305S - 600WS<br />

Very easy and well-arranged operating of KIt® machines<br />

with a possibility of adjusting all parameters<br />

needed for MIG/MAG welding.<br />

One of their main advantages is accurate regulation<br />

of wire speed shift in m/min by 0,1 m/min with<br />

feedback. The regulation of wire speed shift - solved<br />

in such a way - offers precise adjustment of<br />

required parameters and thus it contributes to reaching<br />

excellent welding results.<br />

Two well-arranged displays show all adjusted and<br />

measured parameters such as speed of wire shift in<br />

KIT 600WS<br />

WITH GUSAG<br />

(2 m)<br />

desIGn control panel<br />

desIGn control panel<br />

standard<br />

soUrce<br />

proc. + syn.<br />

soUrce<br />

WIre<br />

feeder<br />

standard<br />

soUrce<br />

proc. + syn.<br />

soUrce<br />

WIre<br />

feeder<br />

m/min, as of gas foreblow and gas after-blow, as of<br />

burning out and so on. During welding process the<br />

welding parameters (voltage and welding current)<br />

are shown on the displays and stored in the memory<br />

with a possibility of their back recalling.<br />

Type SYNERGIC, in addition, very simplifies adjusting<br />

of welding parameters. By easy adjusting the<br />

diameter of wire and used protective gas the staff<br />

determines type of welding programme. Further<br />

the staff sets current by switch and SYNERGIC choses<br />

the best feed speed of wire. Machines SYNER-<br />

GIC also enables saving welding parameters and<br />

own programming.