Instructions - Rittal

Instructions - Rittal

Instructions - Rittal

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

6 Commissioning<br />

The recooling unit does not have its own main<br />

switch to switch the recooling unit on and off. It must<br />

be switched on and off by the higher-level controller.<br />

6.1 Antifreeze<br />

As standard, the units are not suitable for operation<br />

below the specified minimum temperature (see<br />

chapter 11). The units are always to be used with a<br />

water-glycol mixture for the coolant with a maximum<br />

glycol content of between 20 and 30% by volume.<br />

The recommended antifreeze is Antifrogen N or our<br />

<strong>Rittal</strong> Rifrost.<br />

Other types of antifreeze are possible in specific<br />

cases, however only in consultation with the manufacturer.<br />

Note!<br />

Only use distilled or de-ionised water in<br />

recooling units specified for such use (see<br />

chapter 11).<br />

Caution!<br />

Risk of damage for pipes and seals!<br />

Other additives may damage the pipes<br />

and the seal on the cooling medium<br />

pump and are therefore not allowed.<br />

To prevent problems in the cooling medium circuit<br />

(also water-cooled units), it is imperative that the<br />

VEB Cooling Medium Guidelines (VGB-R 455 P) are<br />

observed.<br />

You can read and determine the correct glycol content<br />

with the aid of a refractometer, available from<br />

the following supplier: Georg Pforr -gefo- GmbH &<br />

Co. KG, Holterkamp 16, D-40880 Ratingen, Germany.<br />

http://www.gefo.de.<br />

6.2 Filling the recooling system with<br />

cooling medium<br />

The composition of the cooling medium is described<br />

in chapter 8.<br />

For commissioning, proceed as follows:<br />

Ensure that any shut-off valves installed in the cooling<br />

medium circuit are open.<br />

1<br />

6 Commissioning<br />

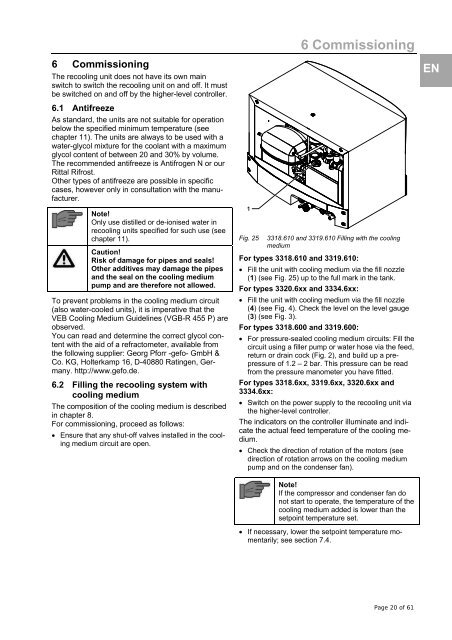

Fig. 25 3318.610 and 3319.610 Filling with the cooling<br />

medium<br />

For types 3318.610 and 3319.610:<br />

Fill the unit with cooling medium via the fill nozzle<br />

(1) (see Fig. 25) up to the full mark in the tank.<br />

For types 3320.6xx and 3334.6xx:<br />

Fill the unit with cooling medium via the fill nozzle<br />

(4) (see Fig. 4). Check the level on the level gauge<br />

(3) (see Fig. 3).<br />

For types 3318.600 and 3319.600:<br />

For pressure-sealed cooling medium circuits: Fill the<br />

circuit using a filler pump or water hose via the feed,<br />

return or drain cock (Fig. 2), and build up a prepressure<br />

of 1.2 – 2 bar. This pressure can be read<br />

from the pressure manometer you have fitted.<br />

For types 3318.6xx, 3319.6xx, 3320.6xx and<br />

3334.6xx:<br />

Switch on the power supply to the recooling unit via<br />

the higher-level controller.<br />

The indicators on the controller illuminate and indicate<br />

the actual feed temperature of the cooling medium.<br />

Check the direction of rotation of the motors (see<br />

direction of rotation arrows on the cooling medium<br />

pump and on the condenser fan).<br />

Note!<br />

If the compressor and condenser fan do<br />

not start to operate, the temperature of the<br />

cooling medium added is lower than the<br />

setpoint temperature set.<br />

If necessary, lower the setpoint temperature momentarily;<br />

see section 7.4.<br />

Page 20 of 61<br />

EN