CITY OF PINOLE Sewer Rehabilitation Program FY 07 – 08 PHASE 2

CITY OF PINOLE Sewer Rehabilitation Program FY 07 – 08 PHASE 2

CITY OF PINOLE Sewer Rehabilitation Program FY 07 – 08 PHASE 2

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

The Contractor must provide proof of successful installation of CIPP rehabilitation<br />

projects on line sizes similar to this project in the state of California. In addition the<br />

Contractor & Manufacturer must have experience installing a minimum of 50,000 feet of<br />

cured-in-place product in wastewater collection systems. Installer’s project managers<br />

must have a minimum of 2 years experience of CIPP installation and must be on-site<br />

during the installation of the CIPP products. The person in charge of operating the<br />

remote control cutting operations to reinstate laterals shall have performed a minimum of<br />

fifty (50) successful remote cutting operations on 6-inch pipelines.<br />

MATERIALS<br />

All pipe shall be handled and stored as recommended by the manufacturer to maintain<br />

integrity. The Contractor shall submit the manufacturer’s recommendations to the<br />

Engineer for approval. All materials deemed damaged by the Engineer shall be removed<br />

from the project site and all expensed incurred shall be paid for by the Contractor.<br />

The tube shall be a material compatible with the resin system (designed for use in a<br />

wastewater environment) used to allow the tube to reach its full strength and size<br />

capacity. The tube shall be properly sized to fit tightly against the inner wall of the host<br />

pipe. The resin and pipe shall meet the structural and chemical resistance requirements in<br />

applicable sections of ASTM F1216/F1743.<br />

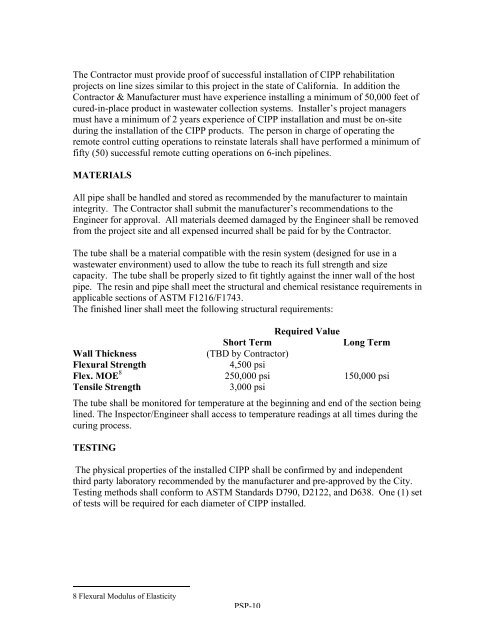

The finished liner shall meet the following structural requirements:<br />

Required Value<br />

Short Term Long Term<br />

Wall Thickness (TBD by Contractor)<br />

Flexural Strength 4,500 psi<br />

Flex. MOE 8<br />

250,000 psi 150,000 psi<br />

Tensile Strength 3,000 psi<br />

The tube shall be monitored for temperature at the beginning and end of the section being<br />

lined. The Inspector/Engineer shall access to temperature readings at all times during the<br />

curing process.<br />

TESTING<br />

The physical properties of the installed CIPP shall be confirmed by and independent<br />

third party laboratory recommended by the manufacturer and pre-approved by the City.<br />

Testing methods shall conform to ASTM Standards D790, D2122, and D638. One (1) set<br />

of tests will be required for each diameter of CIPP installed.<br />

8 Flexural Modulus of Elasticity<br />

PSP-10