CITY OF PINOLE Sewer Rehabilitation Program FY 07 – 08 PHASE 2

CITY OF PINOLE Sewer Rehabilitation Program FY 07 – 08 PHASE 2

CITY OF PINOLE Sewer Rehabilitation Program FY 07 – 08 PHASE 2

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

The Contractor shall be responsible for all costs associated with the chemical<br />

resistance tests.<br />

Proof of meeting these requirements shall be provided to the engineer for<br />

approval at least seven (7) days prior to commencement of work.<br />

2.04 COMPONENT PROPERTIES<br />

A. FIBERGLASS TUBING<br />

The fiberglass tubing shall be made of non-corrosion material in Advantex<br />

(ECR) quality and shall be free from tears, holes, cuts, foreign materials and<br />

other surface defects.<br />

B. RESINS<br />

The physical properties quoted in Section 2.06 apply to CIPP manufactured<br />

polyester or vinylester resin. Resins should be appropriate for conditions<br />

encountered.<br />

2.05 FINISHED AND CURED CIPP LINER PROPERTIES<br />

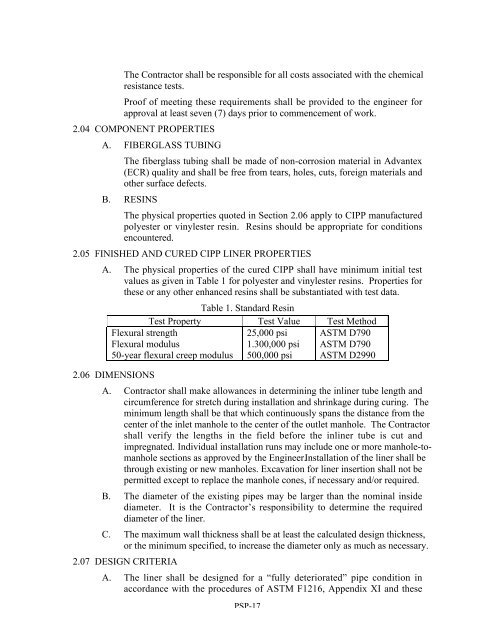

A. The physical properties of the cured CIPP shall have minimum initial test<br />

values as given in Table 1 for polyester and vinylester resins. Properties for<br />

these or any other enhanced resins shall be substantiated with test data.<br />

Table 1. Standard Resin<br />

Test Property Test Value Test Method<br />

Flexural strength<br />

Flexural modulus<br />

50-year flexural creep modulus<br />

25,000 psi<br />

1.300,000 psi<br />

500,000 psi<br />

2.06 DIMENSIONS<br />

A. Contractor shall make allowances in determining the inliner tube length and<br />

circumference for stretch during installation and shrinkage during curing. The<br />

minimum length shall be that which continuously spans the distance from the<br />

center of the inlet manhole to the center of the outlet manhole. The Contractor<br />

shall verify the lengths in the field before the inliner tube is cut and<br />

impregnated. Individual installation runs may include one or more manhole-tomanhole<br />

sections as approved by the Engineer. Installation of the liner shall be<br />

through existing or new manholes. Excavation for liner insertion shall not be<br />

permitted except to replace the manhole cones, if necessary and/or required.<br />

B. The diameter of the existing pipes may be larger than the nominal inside<br />

diameter. It is the Contractor’s responsibility to determine the required<br />

diameter of the liner.<br />

C. The maximum wall thickness shall be at least the calculated design thickness,<br />

or the minimum specified, to increase the diameter only as much as necessary.<br />

2.<strong>07</strong> DESIGN CRITERIA<br />

A. The liner shall be designed for a “fully deteriorated” pipe condition in<br />

accordance with the procedures of ASTM F1216, Appendix XI and these<br />

PSP-17<br />

ASTM D790<br />

ASTM D790<br />

ASTM D2990