CITY OF PINOLE Sewer Rehabilitation Program FY 07 – 08 PHASE 2

CITY OF PINOLE Sewer Rehabilitation Program FY 07 – 08 PHASE 2

CITY OF PINOLE Sewer Rehabilitation Program FY 07 – 08 PHASE 2

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

ASTM F1743 whichever is applicable) for all formula calculations.<br />

6. Manhole connection details.<br />

PART 2 <strong>–</strong> PRODUCTS<br />

2.01 GENERAL<br />

A. All materials and installation procedures provided by the Contractor for use in<br />

the CIPP installation process shall be equal to or exceed the requirements of<br />

Sections 5 and 7 of ASTM F1216 or ASTM F2019 Section 5 and 6, as is<br />

applicable.<br />

B. Wrinkles in the finished liner pipe which cause a backwater of one (1) inch or<br />

more or reduce the hydraulic capacity of the pipe (wrinkles which exceed five<br />

(5) percent of the pipe diameter) are unacceptable and shall be removed or<br />

repaired by the Contractor at no additional cost to the Owner. Wrinkles in the<br />

finished liner pipe that reduce the structural stability of the pipe are<br />

unacceptable. If a void between the wrinkle and the pipe exists, the Contractor<br />

shall repair or replace that section of the pipe at no additional cost to the<br />

Owner. Methods of repair shall be proposed by the Contractor and submitted<br />

to the Engineer for review.<br />

C. Contractor shall be responsible for control of all material and process variables<br />

to provide a finished CIPP possessing the minimum properties specified in<br />

ASTM F1216 or ASTM F2019, as is applicable and supplemented herein.<br />

2.02 MANUFACTURERS<br />

A. Approved CIPP liner manufacturers are LightStream by International Pipe<br />

Lining Technologies.<br />

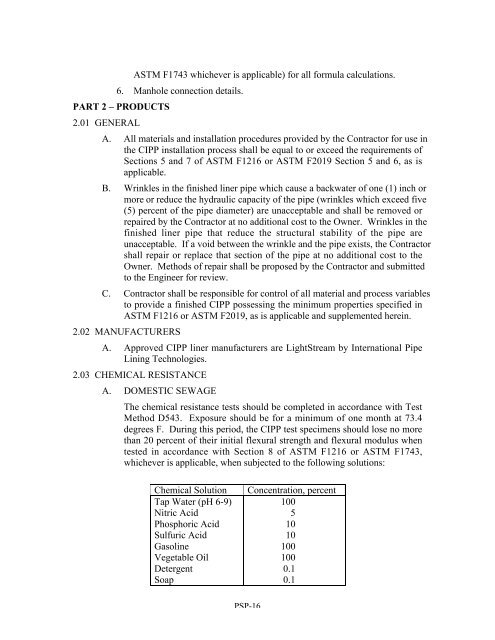

2.03 CHEMICAL RESISTANCE<br />

A. DOMESTIC SEWAGE<br />

The chemical resistance tests should be completed in accordance with Test<br />

Method D543. Exposure should be for a minimum of one month at 73.4<br />

degrees F. During this period, the CIPP test specimens should lose no more<br />

than 20 percent of their initial flexural strength and flexural modulus when<br />

tested in accordance with Section 8 of ASTM F1216 or ASTM F1743,<br />

whichever is applicable, when subjected to the following solutions:<br />

Chemical Solution Concentration, percent<br />

Tap Water (pH 6-9)<br />

Nitric Acid<br />

Phosphoric Acid<br />

Sulfuric Acid<br />

Gasoline<br />

Vegetable Oil<br />

Detergent<br />

Soap<br />

PSP-16<br />

100<br />

5<br />

10<br />

10<br />

100<br />

100<br />

0.1<br />

0.1