- Page 1 and 2:

TRANSITION METAL-CATALYZED REACTION

- Page 3 and 4:

Transition Metal-Catalyzed Reaction

- Page 5 and 6:

List of Abbreviations Ac acetyl AcO

- Page 7 and 8:

Table of Contents 1.0 Introduction.

- Page 9 and 10:

Appendix A : X-ray crystal structur

- Page 11 and 12:

Table 4.8 Rh(I)-catalyzed cyclocarb

- Page 13 and 14:

List of Schemes Scheme 1.1 Three fo

- Page 15 and 16:

Scheme 3.24 Preparation of amide-te

- Page 17 and 18:

Scheme 4.16 Formation of bicyclo[5.

- Page 19 and 20:

1.0 Introduction 1.1 The Role of Di

- Page 21 and 22:

According to these guidelines, the

- Page 23 and 24:

Scheme 1.1 Three forms of diversity

- Page 25 and 26:

Another example from the Schreiber

- Page 27 and 28:

1.1.1 Transition Metal-Catalyzed Re

- Page 29 and 30:

37, , such reactions include transi

- Page 31 and 32:

the proximal olefin of allenyne 38

- Page 33 and 34: 2.0 Design and Synthesis of the Piv

- Page 35 and 36: The allenic amino acid derivatives

- Page 37 and 38: This protocol proved particularly u

- Page 39 and 40: ZnCl2, which results in a Zn-chelat

- Page 41 and 42: Scheme 2.7 Synthesis of trisubstitu

- Page 43 and 44: THF), the yield was increased from

- Page 45 and 46: the terminus of the alkyne led to d

- Page 47 and 48: N-Alkylation of the glycine-derived

- Page 49 and 50: circumvent this issue, variants suc

- Page 51 and 52: BINAP as a chiral ligand to obtain

- Page 53 and 54: stereochemistry of the exocyclic ol

- Page 55 and 56: 3.2 Rhodium(I)-Catalyzed Allenic Cy

- Page 57 and 58: exocyclic olefin geometry is not re

- Page 59 and 60: 3.2.1 Preparation of Enol-ether Tri

- Page 61 and 62: Scheme 3.15 Synthesis of cycloisome

- Page 63 and 64: Scheme 3.17 Cycloisomerization of a

- Page 65 and 66: Scheme 3.19 Tandem cycloadditions o

- Page 67 and 68: Scheme 3.21 Intermolecular Diels-Al

- Page 69 and 70: attractive, since additional functi

- Page 71 and 72: increased yield of the triene (47%)

- Page 73 and 74: as an isobutyl-amide 155b was prepa

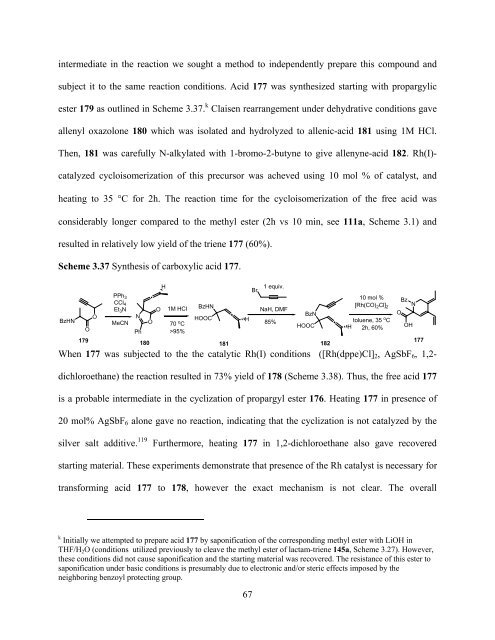

- Page 75 and 76: group) demonstrated that this cyclo

- Page 77 and 78: in 1M HCl/dioxane (1 : 1) for 1h, t

- Page 79 and 80: ppm (dd, J = 7.1, 4.6 Hz, 1H) assig

- Page 81 and 82: http://ccc.chem.pitt.edu/). Using f

- Page 83: Notably, exclusive cycloisomerizati

- Page 87 and 88: epulsive dipole interactions (Schem

- Page 89 and 90: Table 3.4 Diels-Alder reactions of

- Page 91 and 92: allenic Alder-ene reaction, ene-all

- Page 93 and 94: Figure 3.4 Examples of natural prod

- Page 95 and 96: species onto the proximal double bo

- Page 97 and 98: Scheme 3.49 Rh(I)-catalyzed ene rea

- Page 99 and 100: y Magnus 144 and it involves the in

- Page 101 and 102: usually is DMSO. Heating to 100 ºC

- Page 103 and 104: that require high pressures of CO.

- Page 105 and 106: In contrast to the Mo(CO)6-mediated

- Page 107 and 108: Scheme 4.15 Rh(I)-catalyzed allenic

- Page 109 and 110: 4.2 Rhodium(I)-Catalyzed Cyclocarbo

- Page 111 and 112: lack of double bond selectivity, si

- Page 113 and 114: Table 4.2 Cyclocarbonylation reacti

- Page 115 and 116: Notably, the allenic cyclocarbonyla

- Page 117 and 118: Scheme 4.22 Cyclocarbonylation reac

- Page 119 and 120: neat or in solution. This decomposi

- Page 121 and 122: the newly synthesized fulvenes (e.g

- Page 123 and 124: stereocenters and mixture of E/Z is

- Page 125 and 126: proximal double bond to give α-alk

- Page 127 and 128: the methyl ester and Ha are syn. Sc

- Page 129 and 130: that the major diastereomer in the

- Page 131 and 132: We were motivated to first examine

- Page 133 and 134: Scheme 4.42 Synthesis of pyrrole 29

- Page 135 and 136:

periodic acid (H5IO6). 209 These hi

- Page 137 and 138:

eaction failed to go to completion,

- Page 139 and 140:

4.5.2 Synthesis of a Library of Tri

- Page 141 and 142:

diketones 312{1-3,1-2} in yields ra

- Page 143 and 144:

Figure 4.2 Distribution for physico

- Page 145 and 146:

tricyclic pyrrole 314{3,2,26} (Figu

- Page 147 and 148:

4.6 Synthesis of α-Alkylidene Cycl

- Page 149 and 150:

anched and linear carboxylic acid i

- Page 151 and 152:

eactivity of the species prepared i

- Page 153 and 154:

considerably lower than the ratio o

- Page 155 and 156:

diastereomer. Next, allenyne 328 wa

- Page 157 and 158:

Conclusions In summary, we have dem

- Page 159 and 160:

Experimental Section General Method

- Page 161 and 162:

General procedure A for esterificat

- Page 163 and 164:

F Bz N H 56f 2-Benzoylamino-3-(4-fl

- Page 165 and 166:

MeO2C Bz N H 58c 2-Benzoylamino-2-m

- Page 167 and 168:

MeO MeO2C Bz N H 58e 2-Benzoylamino

- Page 169 and 170:

mL) and MeOH (10 mL) instead of sat

- Page 171 and 172:

hexanes-EtOAc, 19 : 1 to 4 : 1, v/v

- Page 173 and 174:

which was immediately used in the C

- Page 175 and 176:

Boc TMS N H Bn 64f tert-Butyl-1-((4

- Page 177 and 178:

MeI (38 µL, 0.62 mmol). Yield 65a

- Page 179 and 180:

with brine and concentrated under v

- Page 181 and 182:

H MeO 2C • H Bn NHBoc tert-Butyl-

- Page 183 and 184:

TMS MeO 2C • 70 H H NHBoc 2-tert-

- Page 185 and 186:

185 (10), 141 (21), 57 (100); EI-HR

- Page 187 and 188:

dispersion in mineral oil, 1.0 mmol

- Page 189 and 190:

EI-HRMS calcd for C30H26NO3 m/z [M-

- Page 191 and 192:

CbzN MeO 2C Me 73h 2-[Benzyloxycarb

- Page 193 and 194:

CbzN MeO 2C Me 2-(Benzyloxycarbonyl

- Page 195 and 196:

dispersion in mineral oil, 3.85 mmo

- Page 197 and 198:

completion of the addition, the rea

- Page 199 and 200:

BzN MeO 2C S 74h 2-(Benzoylprop-2-y

- Page 201 and 202:

BzN MeO 2C Bn 75b 2-(Allylbenzoylam

- Page 203 and 204:

BzN MeO 2C TBSO 75e 2-(Benzoylbut-2

- Page 205 and 206:

Hz, 1H), 5.85 (s, 1H), 5.52 (dd, J

- Page 207 and 208:

1H), 3.69 (s, 3H), 1.58 (d, J = 7.1

- Page 209 and 210:

µmol), [Rh(CO)2Cl]2 (1 mg, 3 µmol

- Page 211 and 212:

1.25 (m, 6H), 0.88 (t, J = 6.9 Hz,

- Page 213 and 214:

6.72 (d, J = 7.6 Hz, 0.5H), 6.68 (d

- Page 215 and 216:

BzN MeO2C Bn 122a Methyl-2-(N-(but-

- Page 217 and 218:

Bz N MeO2C Bn 1-Benzoyl-2-benzyl-4-

- Page 219 and 220:

13.9, 5.3 Hz, 1H), 2.51-2.47 (m, 1H

- Page 221 and 222:

15 min the solvent was removed unde

- Page 223 and 224:

Benzoyl chloride (0.169 mL, 1.46 mm

- Page 225 and 226:

mg, 0.11 mmol), [Rh(CO)2Cl]2 (4 mg,

- Page 227 and 228:

mL). kk The aqueous layer was extra

- Page 229 and 230:

ºC. After quenching the reaction b

- Page 231 and 232:

129.8, 129.0, 128.7, 128.4, 126.2,

- Page 233 and 234:

MeO 2C O O O N H N R 1 O N Ph [10c-

- Page 235 and 236:

The crude residue was purified by f

- Page 237 and 238:

14.4 Hz, 1H), 3.49-3.39 (m, 2H), 3.

- Page 239 and 240:

1H), 5.49 (dd, J = 17.3, 1.8 Hz, 1H

- Page 241 and 242:

was stirred at rt for 1 h when it w

- Page 243 and 244:

BzN HOOC 2-(N-(but-2-ynyl)benzamido

- Page 245 and 246:

°C and DIBAL-H (0.440 mL of a 1.0M

- Page 247 and 248:

129 (62), 91 (100); EI-HRMS calcula

- Page 249 and 250:

(d, J = 18.0 Hz, 1H), 4.14 (d, J =

- Page 251 and 252:

4.98 (dt, J = 7.7, 5.1 Hz, 1H), 4.1

- Page 253 and 254:

N Bz MeO2C OTBS 214 1-Benzoyl-2-(te

- Page 255 and 256:

270a (major diastereomer-eluting fi

- Page 257 and 258:

CDCl3): δ 7.42-7.17 (m, 13H), 7.04

- Page 259 and 260:

18.6 Hz, 1H), 4.34 (d, J = 18.0 Hz,

- Page 261 and 262:

Bz N MeO2C 2-Benzoyl-3,7-dimethyl-6

- Page 263 and 264:

v/v) afforded a mixture of compound

- Page 265 and 266:

(435 mg, 1.21 mmol), DMSO (429 µL,

- Page 267 and 268:

4.02 (s, 1H), 3.88 (s, 3H), 1.82 (s

- Page 269 and 270:

(207 mg, 96%) consisting of 287e (7

- Page 271 and 272:

procedure O, using: 74f (110 mg, 0.

- Page 273 and 274:

Bz N O H CO2Me BocN 287i 3-(2-Benzo

- Page 275 and 276:

4.17 (d, J = 15.0 Hz, 1H), 4.10 (d,

- Page 277 and 278:

137.1, 136.9, 130.4, 129.8, 128.5,

- Page 279 and 280:

H BzN MeO2C Bn H N C3H7 298b CO 2Me

- Page 281 and 282:

NMR (75 MHz, CDCl3): δ 172.3, 169.

- Page 283 and 284:

following the general procedure Q,

- Page 285 and 286:

H BzN MeO2C Bn H 5-Benzoyl-1,4-dibe

- Page 287 and 288:

119.9, 114.1, 109.9, 108.6, 73.0, 5

- Page 289 and 290:

4.11 (m, 1H), 4.07-3.98 (m, 1H), 3.

- Page 291 and 292:

126.8, 126.2, 109.0, 72.9, 58.7, 56

- Page 293 and 294:

NMR (75 MHz, CDCl3): δ 172.2, 169.

- Page 295 and 296:

3.0 Hz, 1H), 5.82-5.80 (m, 1H), 5.2

- Page 297 and 298:

87%). The diastereomeric ratio (288

- Page 299 and 300:

APPENDIX A: X-ray crystal structure

- Page 301 and 302:

APPENDIX B: X-ray crystal structure

- Page 303 and 304:

APPENDIX C: X-ray crystal structure

- Page 305 and 306:

APPENDIX D: X-ray crystal structure

- Page 307 and 308:

APPENDIX E: X-ray crystal structure

- Page 309 and 310:

APPENDIX F: QikProp property predic

- Page 311 and 312:

1 H and 13 C NMRs of 74b 293

- Page 313 and 314:

1 H and 13 C NMRs of 111a 295

- Page 315 and 316:

1 H and 13 C NMRs of 155a 297

- Page 317 and 318:

1 H and 13 C NMRs of 156a 299

- Page 319 and 320:

1 H and 13 C NMRs of 186b 301

- Page 321 and 322:

1 H and 13 C NMRs of 270h 303

- Page 323 and 324:

1 H and 13 C NMRs of 287b 305

- Page 325 and 326:

1 H and 13 C NMRs of 307 307

- Page 327 and 328:

1 H and 13 C NMRs of 308n 309

- Page 329 and 330:

10. (a) Burke, M. D.; Schreiber, S.

- Page 331 and 332:

Hu, Y. J. Comb. Chem. 2006, 8, 286.

- Page 333 and 334:

49. For reviews on reactions of all

- Page 335 and 336:

69. (a) Trost, B. M.; Lautens, M.;

- Page 337 and 338:

containing cross-conjugated trienes

- Page 339 and 340:

Vaillancourt, J.; Rasper, D. M.; Ta

- Page 341 and 342:

130. Oppolzer, W.; Snieckus, V. Ang

- Page 343 and 344:

149. (a) Hicks, F. A.; Buchwald, S.

- Page 345 and 346:

Maiese, W. M. J. Antibiot. 2000, 53

- Page 347 and 348:

192. The mechanism of decomposition

- Page 349 and 350:

Boger, D. L.; Boyce, C. W.; Labroli

- Page 351:

Generated Inhibitors of Human Mitog