SCEBs - University of Colorado Boulder

SCEBs - University of Colorado Boulder

SCEBs - University of Colorado Boulder

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

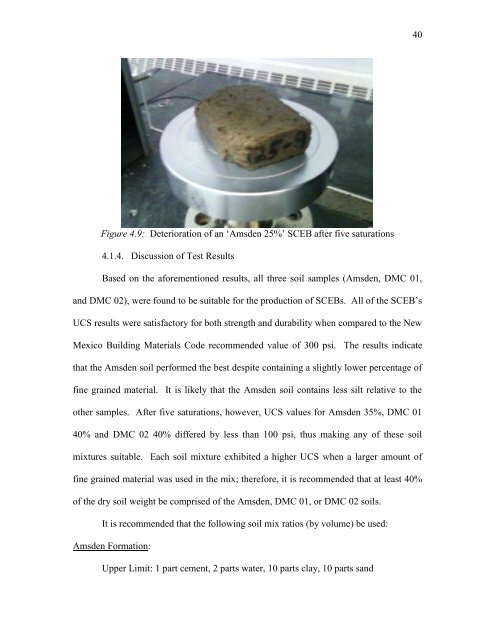

Figure 4.9: Deterioration <strong>of</strong> an „Amsden 25%‟ SCEB after five saturations<br />

4.1.4. Discussion <strong>of</strong> Test Results<br />

Based on the aforementioned results, all three soil samples (Amsden, DMC 01,<br />

and DMC 02), were found to be suitable for the production <strong>of</strong> <strong>SCEBs</strong>. All <strong>of</strong> the SCEB‟s<br />

UCS results were satisfactory for both strength and durability when compared to the New<br />

Mexico Building Materials Code recommended value <strong>of</strong> 300 psi. The results indicate<br />

that the Amsden soil performed the best despite containing a slightly lower percentage <strong>of</strong><br />

fine grained material. It is likely that the Amsden soil contains less silt relative to the<br />

other samples. After five saturations, however, UCS values for Amsden 35%, DMC 01<br />

40% and DMC 02 40% differed by less than 100 psi, thus making any <strong>of</strong> these soil<br />

mixtures suitable. Each soil mixture exhibited a higher UCS when a larger amount <strong>of</strong><br />

fine grained material was used in the mix; therefore, it is recommended that at least 40%<br />

<strong>of</strong> the dry soil weight be comprised <strong>of</strong> the Amsden, DMC 01, or DMC 02 soils.<br />

It is recommended that the following soil mix ratios (by volume) be used:<br />

Amsden Formation:<br />

Upper Limit: 1 part cement, 2 parts water, 10 parts clay, 10 parts sand<br />

40