A cArbon cApture And storAge network for yorkshire And humber

A cArbon cApture And storAge network for yorkshire And humber

A cArbon cApture And storAge network for yorkshire And humber

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Table 3.1 Definition of Tier emitter classifications<br />

Figure 1.2 shows the location of the larger<br />

emitters (over 1mtCO2/year) in the study<br />

area. Large thermal power plants are<br />

indicated by red squares and blue dots,<br />

whilst the purple squares represent possible<br />

future projects. Non-energy producers<br />

of CO2 are shown in orange. Yellow dots<br />

shown indicate potential export points;<br />

both shown are Easington (northerly) and<br />

Theddlethorpe (southerly). Although the<br />

existing pipelines and gas export facilities<br />

will not be utilised, it was assumed that it<br />

would be easier to obtain planning consent<br />

if the proposed pipelines crossed the coast<br />

at the same point.<br />

3.3 TIERED SOURCES<br />

3.3.1 Division by emitter flow<br />

Emitters can be ranked by their allowances<br />

allocated under the EU-ETS. This allows<br />

the consideration of an area in terms of not<br />

only size of emitter but also the capability<br />

and economic ability of an emitter to join<br />

a transmission <strong>network</strong>. This methodology<br />

was previously used in a project <strong>for</strong> the<br />

International Energy Agency (IEA GHG)<br />

[14] to test a <strong>network</strong> design and costing<br />

programme. Table 3.1 shows the definitions<br />

applying to the classification of an emitter by<br />

size, and a detailed list of emitters can be<br />

found in Appendix B.<br />

Carbon Capture and Storage Network 9<br />

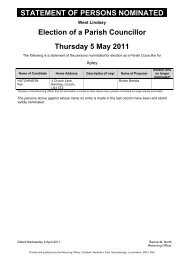

Tier Classification Emitter Size Emitter Range Typical Emitter Types<br />

(Generalisation) Tonnes CO2/year<br />

0 Large +1 million Coal fired power station<br />

Major hydrocarbon refinery<br />

Major steel works<br />

Large CCGT power station<br />

1 Medium 50,000 to 1 million Chemical, glass, food processors,<br />

large CHP & power stations<br />

CCGT power station<br />

2 Small 1,000 to 50,000 CHP units, hospitals,<br />

Varied Industrial process<br />

In considering a <strong>network</strong> and how emitters<br />

can connect to it a number of factors<br />

must be considered including the size of<br />

the emitter, the capacity to capture and<br />

transmit CO2, and the location of the site.<br />

Small emitters such as hospitals will not<br />

necessarily have the technical capability to<br />

operate complex compression equipment<br />

<strong>for</strong> example. By applying tiers to the<br />

emitters in any area a simple but coarse<br />

measure can be applied and some sources,<br />

even whole tiers can be discounted.<br />

It may be more appropriate <strong>for</strong> Tier 1 and<br />

2 sources to be part of a suction system,<br />

transmitting low pressure CO2 to a central<br />

collection point such as larger capable<br />

Tier 0 or Tier 1 sites.<br />

A map of the location of the emitters in<br />

the region is included in figure 3.1 and<br />

Appendix A.<br />

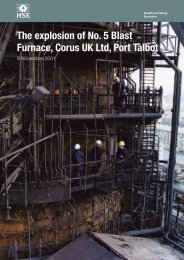

3.3.2 Tier 0 sources<br />

Sources with volumes of CO2 greater than<br />

1mt/year are categorized as Tier 0 sources.<br />

Sources of this magnitude in this area are<br />

power stations, refineries and steel works.<br />

Carbon capture and storage is most<br />

economical in Tier 0 sources due to large<br />

amounts of CO2 available <strong>for</strong> capture, as well<br />

as the availability of land at these sites <strong>for</strong><br />

extraction units. There are 12 such sources<br />

<strong>for</strong> this study.<br />

3.3.3 Tier 1 sources<br />

Sources with volumes of CO2 ranging from<br />

0.05mt/year to 1mt/year are categorized<br />

as Tier 1. These include power and CHP<br />

plants, chemical producers, cement & lime<br />

works, large food & drink producers and<br />

glassworks. Extraction and conditioning<br />

of CO2 from most of these sources is<br />

considered less economic and there is less<br />

drive to reduce CO2 emissions below Best<br />

Available Techniques (BAT).<br />

3.3.4 Tier 2 sources<br />

Those ranging from 1kt CO2/year to<br />

0.5mt CO2/year are Tier 2 sources.<br />

These smaller emitters include local small<br />

power generators, services, hospitals, food<br />

& drink manufacturers as well as small<br />

chemical producers. The relatively small<br />

amounts of CO2 produced at these sites<br />

make them uneconomic or unpractical<br />

<strong>for</strong> CCS, furthermore most are scattered<br />

throughout the area, or located in densely<br />

populated areas, making transportation<br />

of the gas problematic.<br />

3.3.5 proportion of emissions<br />

Emissions taken from the EU-ETS have<br />

resulted in the following proportions shown<br />

in the chart below. The current bulk of the<br />

emissions, 92%, are from Tier 0 sources<br />

and only 8% from combined Tier 1 and<br />

Tier 2 sources, figure 3.4a. Adding future<br />

proposed programmes changes this<br />

proportion to 95.4% <strong>for</strong> Tier 0, figure 3.4b.<br />

This suggests that the trunk line could be<br />

sized to accommodate the Tier 0 emitters,<br />

as there is little impact from smaller emitters<br />

joining the <strong>network</strong>.