S.N.A.K.E.: A Dynamically Reconfigurable Artificial Sensate Skin ...

S.N.A.K.E.: A Dynamically Reconfigurable Artificial Sensate Skin ...

S.N.A.K.E.: A Dynamically Reconfigurable Artificial Sensate Skin ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

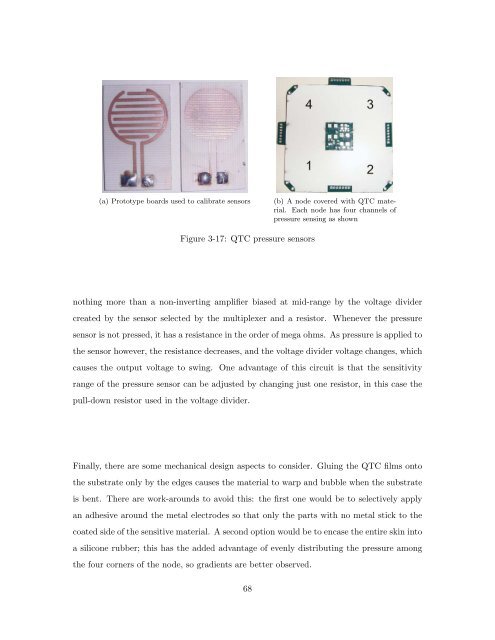

(a) Prototype boards used to calibrate sensors (b) A node covered with QTC material.<br />

Each node has four channels of<br />

pressure sensing as shown<br />

Figure 3-17: QTC pressure sensors<br />

nothing more than a non-inverting amplifier biased at mid-range by the voltage divider<br />

created by the sensor selected by the multiplexer and a resistor. Whenever the pressure<br />

sensor is not pressed, it has a resistance in the order of mega ohms. As pressure is applied to<br />

the sensor however, the resistance decreases, and the voltage divider voltage changes, which<br />

causes the output voltage to swing. One advantage of this circuit is that the sensitivity<br />

range of the pressure sensor can be adjusted by changing just one resistor, in this case the<br />

pull-down resistor used in the voltage divider.<br />

Finally, there are some mechanical design aspects to consider. Gluing the QTC films onto<br />

the substrate only by the edges causes the material to warp and bubble when the substrate<br />

is bent. There are work-arounds to avoid this: the first one would be to selectively apply<br />

an adhesive around the metal electrodes so that only the parts with no metal stick to the<br />

coated side of the sensitive material. A second option would be to encase the entire skin into<br />

a silicone rubber; this has the added advantage of evenly distributing the pressure among<br />

the four corners of the node, so gradients are better observed.<br />

68